Piezoresistive Pressure Sensor

Φ19x11.5mm

0bar~0.35bar…1000bar

Constant Voltage Supply

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM288SA

Used For

Gas and Liquid Pressure Measuring, Level Measurement, Flow Meter Companion Device

Leave a MessageMPM288SA voltage output pressure sensor is a pressure sensitive element with a standard voltage output signal. The product PCBA circuit board consists of a dedicated conditioning chip (ASIC). Dual-channel 24-bit ADC ensures signal high resolution. The pressure measuring device can be assembled or welded to various pressure connections. The shape, assembly dimensions, and sealing method of MPM288SA analog pressure sensor are highly interchangeable with similar international products.

Feature

• φ19mm standard outer diameter

• Mature production technology and signal conditioning technology

• Suitable for on-site pressure measurement instruments

• High interchangeability

Image:

MPM288SA voltage output pressure sensor is a pressure sensitive element with a standard voltage output signal. The product PCBA circuit board consists of a dedicated conditioning chip (ASIC). Dual-channel 24-bit ADC ensures signal high resolution. The pressure measuring device can be assembled or welded to various pressure connections. The shape, assembly dimensions, and sealing method of MPM288SA analog pressure sensor are highly interchangeable with similar international products.

Feature

• φ19mm standard outer diameter

• Mature production technology and signal conditioning technology

• Suitable for on-site pressure measurement instruments

• High interchangeability

Φ19x11.5mm

Pressure range -1bar…0bar~0.07bar… 1000bar

Silicone/Fluorocarbon oil filling options

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

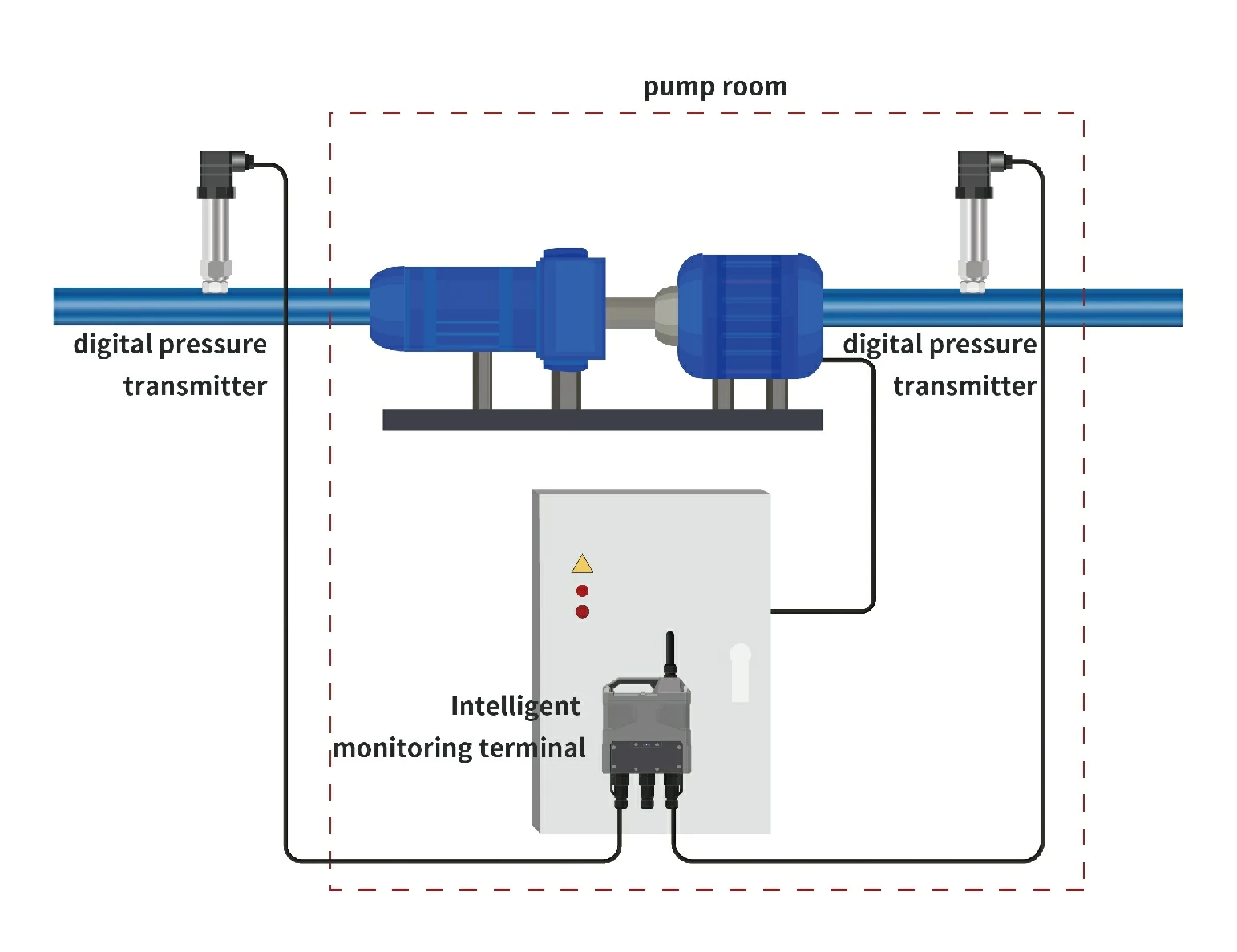

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

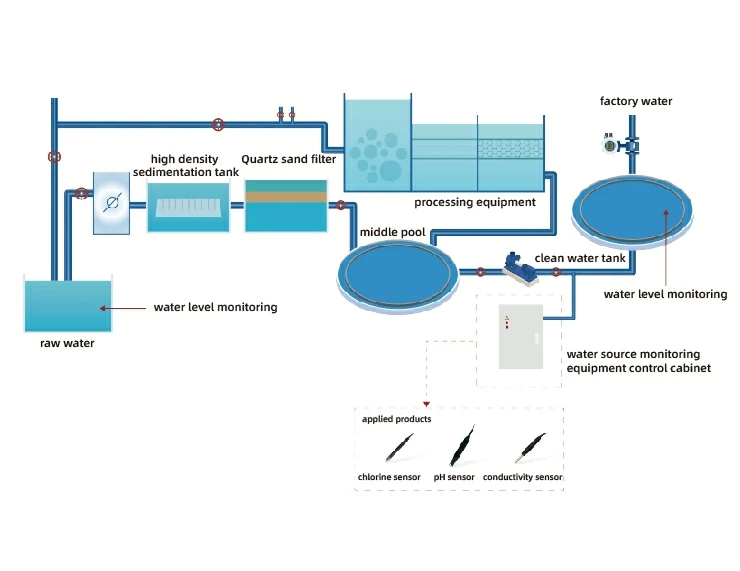

Pressure, flow, and level measuring instruments are deployed in water tanks, pipelines, and water inlets/outlets. This helps to manage the macro-control of production data in the water plant. Measuring instruments ensure smooth operation and normal production.

more info...

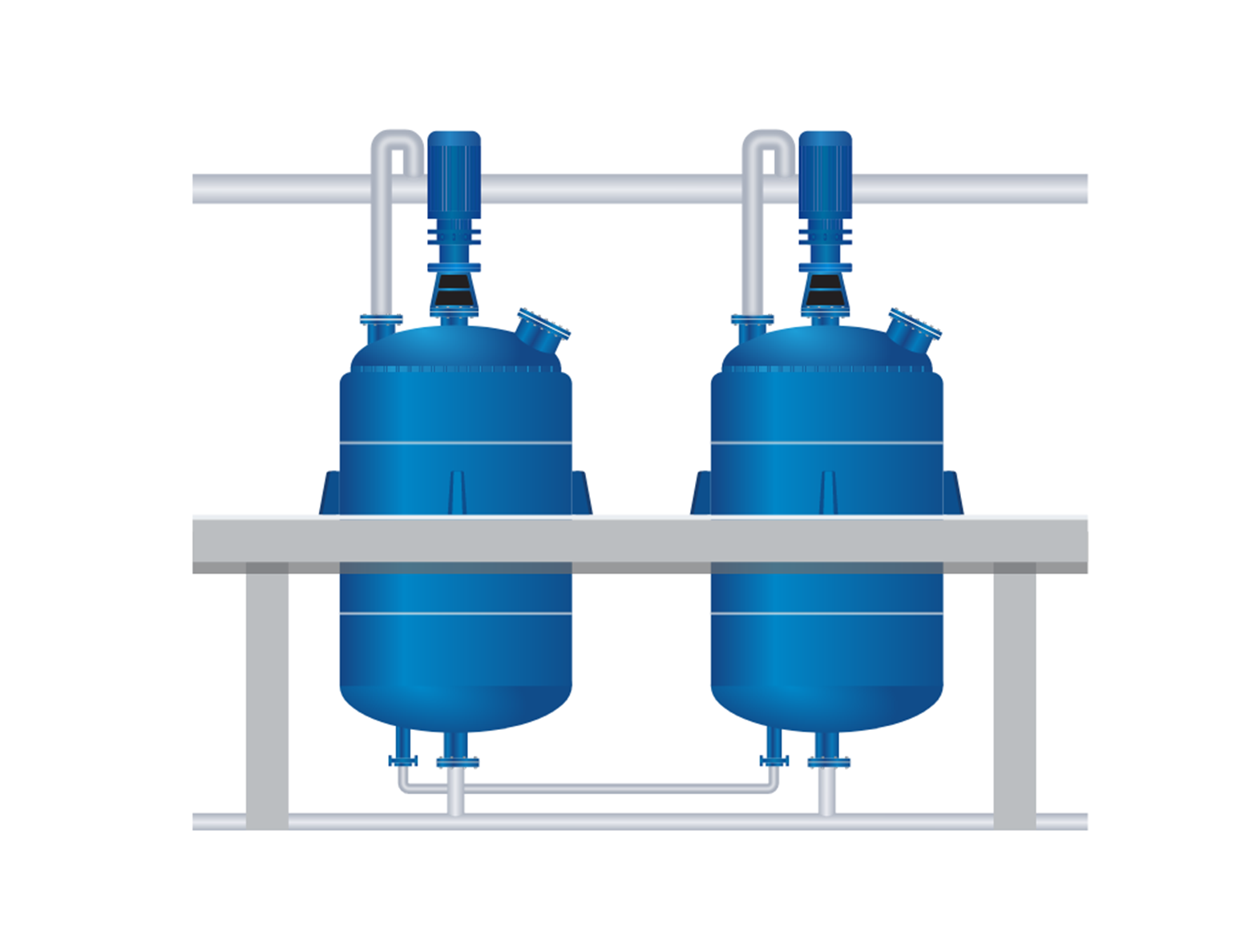

During machine downtime or product changes, the press rolls are cleaned and coated with a specialist solution to protect against adhesions and deposits, hence avoiding paper difficulties. The 50°C coating mixture is pushed through the machine. To maintain automated functioning, the tank's level and filter status must be continuously monitored.

more info...

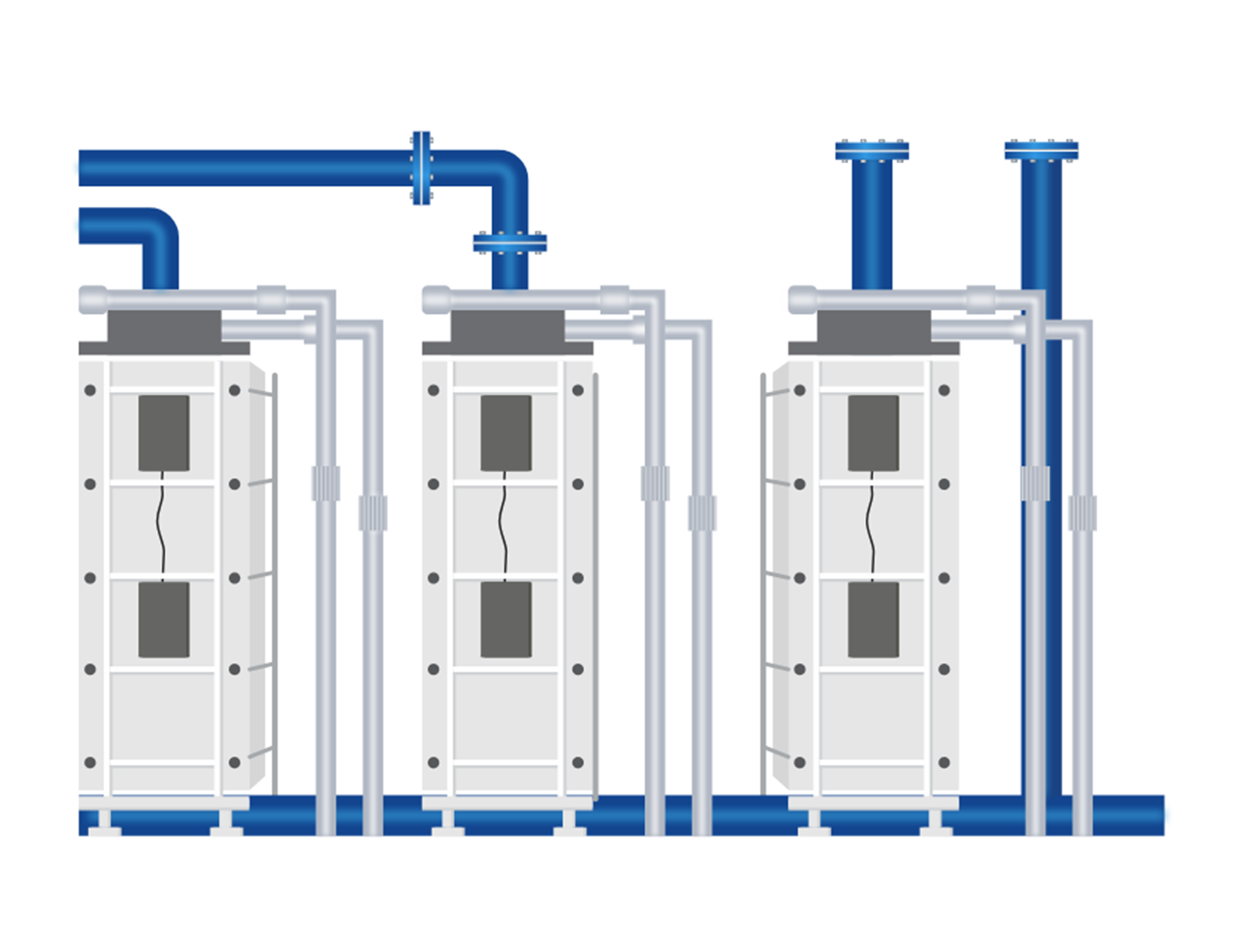

In the paper industry, the alkali recovery system is an essential part that operates under harsh conditions. The system needs strong pressure, temperature, and flow instrumentation to handle high temperatures, high pressures, and corrosive media.

more info...