Hygienic Pressure Sensor

Φ32mm

0bar~0.35bar...35bar

Standard DN25 Clamp Connection

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM281

Used For

General Industrial, Pressure Checking Meter, Pressure Calibrator, Liquid pressure system and Switch, Medical Equipment

Leave a MessageThe MPM281 high-stable pressure sensor is an isolated, precision-compensated OEM piezoresistive pressure measurement element. The pressure sensing elements use patented high-stability diffused silicon components. The MPM281 is packaged in a 316L all-stainless steel structure with an outer diameter of Ф19mm. After precision trimming, the temperature compensation and zero point deviation correction of the imported chips are carried out in a wide temperature range through the thick film circuit. The wide temperature compensation range can reach -10℃~80℃. The MPM281 pressure sensor is used in various measuring instruments to realize the precise conversion of pressure to electrical signals. It can also be used in petrochemical pipeline monitoring, inkjet printer pressure monitoring, flowmeter pressure compensation, medical equipment, and other fields. It is also suitable for industrial automation fields where the site temperature changes greatly, such as oil field sites exposed to the outdoors for a long time.

Features

• Φ19mm standard OEM pressure sensitive element

• High sensitivity, large signal

• Wide temperature compensation, precise conversion

• Multi-medium measurement compatibility

• Long-term stability up to ±0.1%FS/year

Image:

The MPM281 high-stable pressure sensor is an isolated, precision-compensated OEM piezoresistive pressure measurement element. The pressure sensing elements use patented high-stability diffused silicon components. The MPM281 is packaged in a 316L all-stainless steel structure with an outer diameter of Ф19mm. After precision trimming, the temperature compensation and zero point deviation correction of the imported chips are carried out in a wide temperature range through the thick film circuit. The wide temperature compensation range can reach -10℃~80℃. The MPM281 pressure sensor is used in various measuring instruments to realize the precise conversion of pressure to electrical signals. It can also be used in petrochemical pipeline monitoring, inkjet printer pressure monitoring, flowmeter pressure compensation, medical equipment, and other fields. It is also suitable for industrial automation fields where the site temperature changes greatly, such as oil field sites exposed to the outdoors for a long time.

Features

• Φ19mm standard OEM pressure sensitive element

• High sensitivity, large signal

• Wide temperature compensation, precise conversion

• Multi-medium measurement compatibility

• Long-term stability up to ±0.1%FS/year

Range: -1bar…-0.35bar ~ 0bar ~0.35bar…700bar

No need for re-calibration for users, high precision

Customizable dimensions

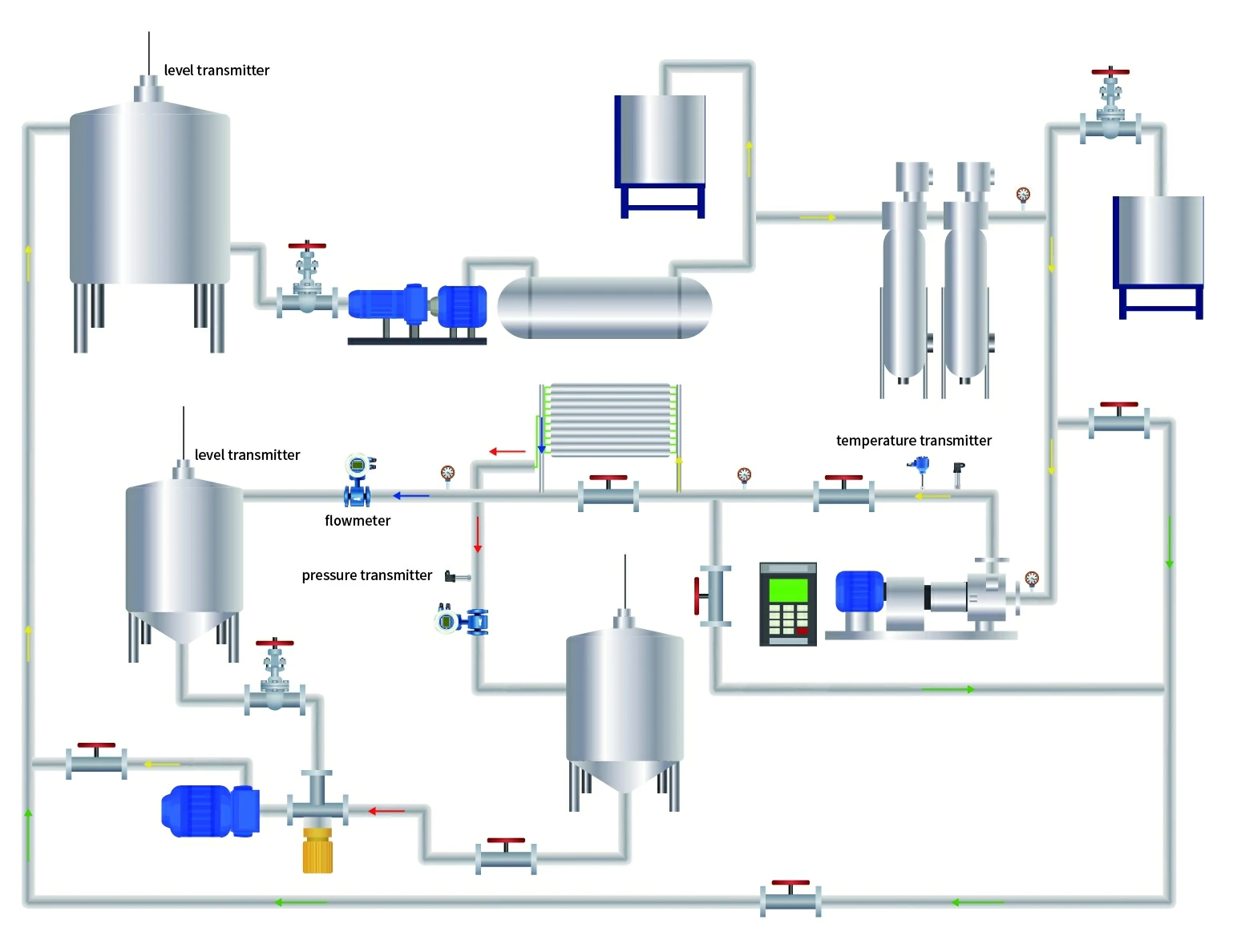

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...

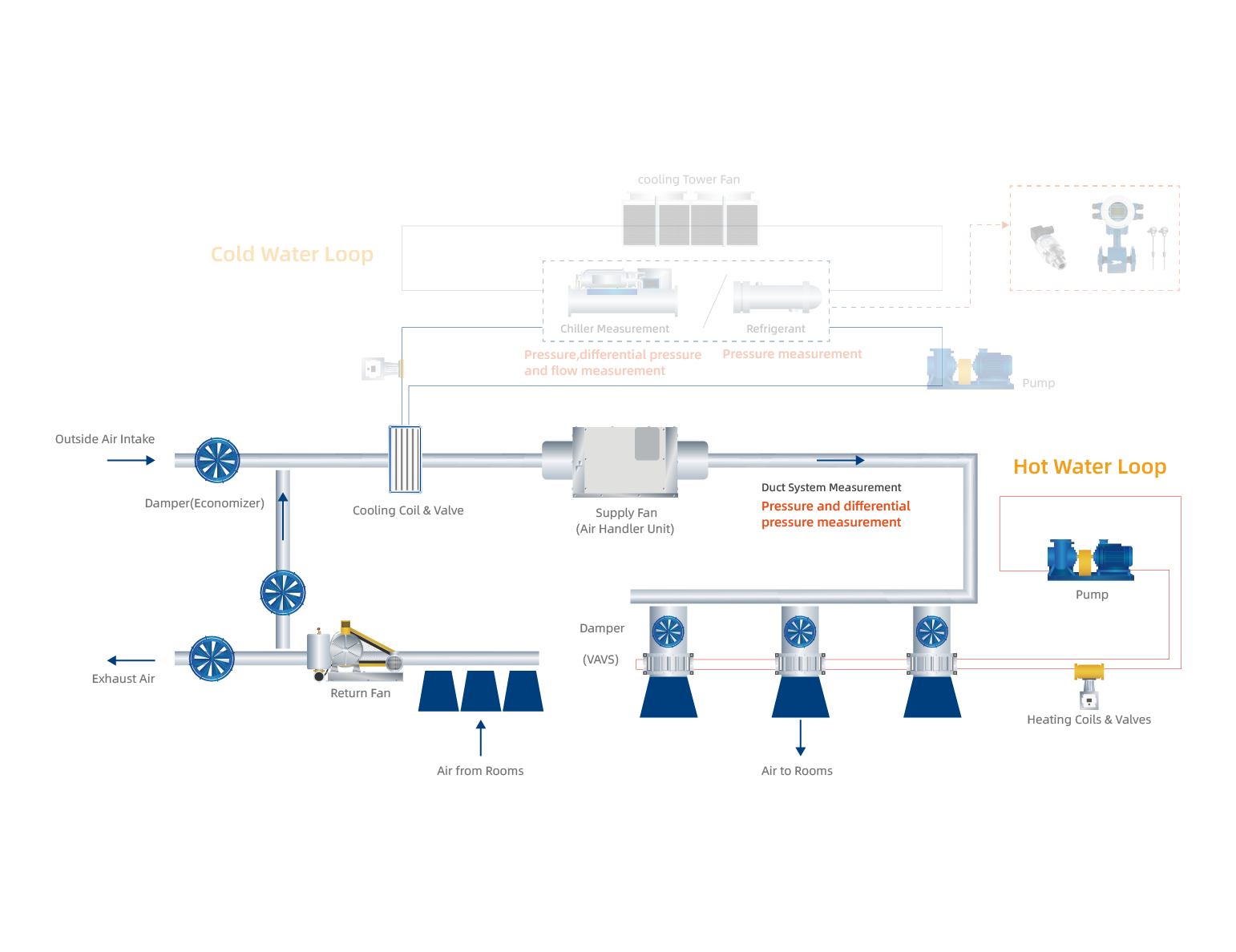

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

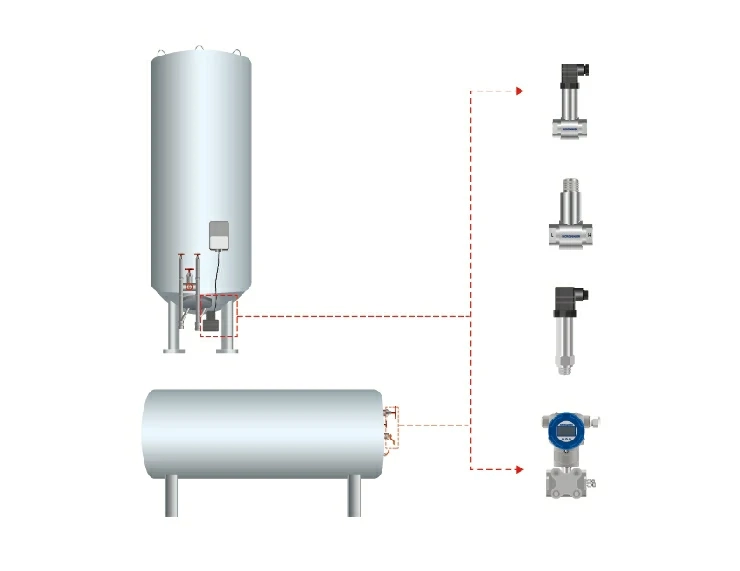

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

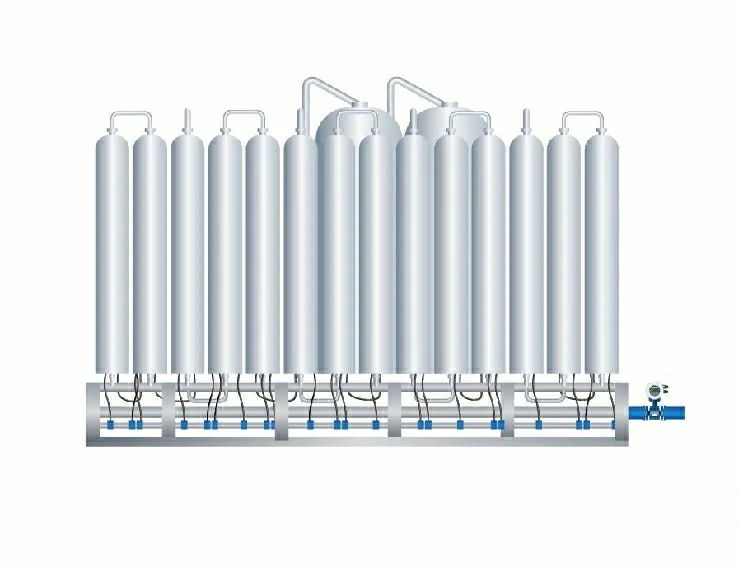

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...