Flushing Ring

Flushing ring: 316 SS

Flange diameter: DN25~DN100, 1-in~4-in

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM280PD1

Used For

Healthcare, Pharmaceuticals, Food & Beverage, Wastewater Treatment

Leave a MessageAs a hygienic pressure sensor and transmitter, the MPM280PD1 piezoresistive silicon pressure sensor is designed for the hygienic applications, with the diaphragm OD32mm which is easier for cleaning. It has isolated construction to measure various fluid media. In addition, a variety of mechanical and electrical configurations are available as standard or customized pressure sensors. This product is available with a choice of constant-current or constant-voltage power supplies.

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 2.5kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulation resistor: 100MΩ@100V DC

• Overpressure: 2 times FS

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Pin: Kovar

• O-ring: FKM

• Net weight: ~148g(PD1)

Features

• Pressure range: 0bar ~ 0.35bar…350bar

• Gauge, Absolute and Sealed gauge

• Thread connection pressure:0bar~0.35bar…350bar

• Clamp connection pressure:0bar~0.35bar~35bar

• Hygienic structure optional (Ra<0.4μm)

• Tnegtive pressure measurement is available, the lowest to around -1bar

Image:

As a hygienic pressure sensor and transmitter, the MPM280PD1 piezoresistive silicon pressure sensor is designed for the hygienic applications, with the diaphragm OD32mm which is easier for cleaning. It has isolated construction to measure various fluid media. In addition, a variety of mechanical and electrical configurations are available as standard or customized pressure sensors. This product is available with a choice of constant-current or constant-voltage power supplies.

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 2.5kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulation resistor: 100MΩ@100V DC

• Overpressure: 2 times FS

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Pin: Kovar

• O-ring: FKM

• Net weight: ~148g(PD1)

Features

• Pressure range: 0bar ~ 0.35bar…350bar

• Gauge, Absolute and Sealed gauge

• Thread connection pressure:0bar~0.35bar…350bar

• Clamp connection pressure:0bar~0.35bar~35bar

• Hygienic structure optional (Ra<0.4μm)

• Tnegtive pressure measurement is available, the lowest to around -1bar

High stability piezoresistive sensor die

Isolated construction, applicable to measuring various fluid

LCD display Corrosion-resistant housing

High accuracy ±0.1% FS

High level EMC protection

Simultaneous hybrid output of 4-20 mA+RS485

Intrinsically safe and explosion proof certification

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

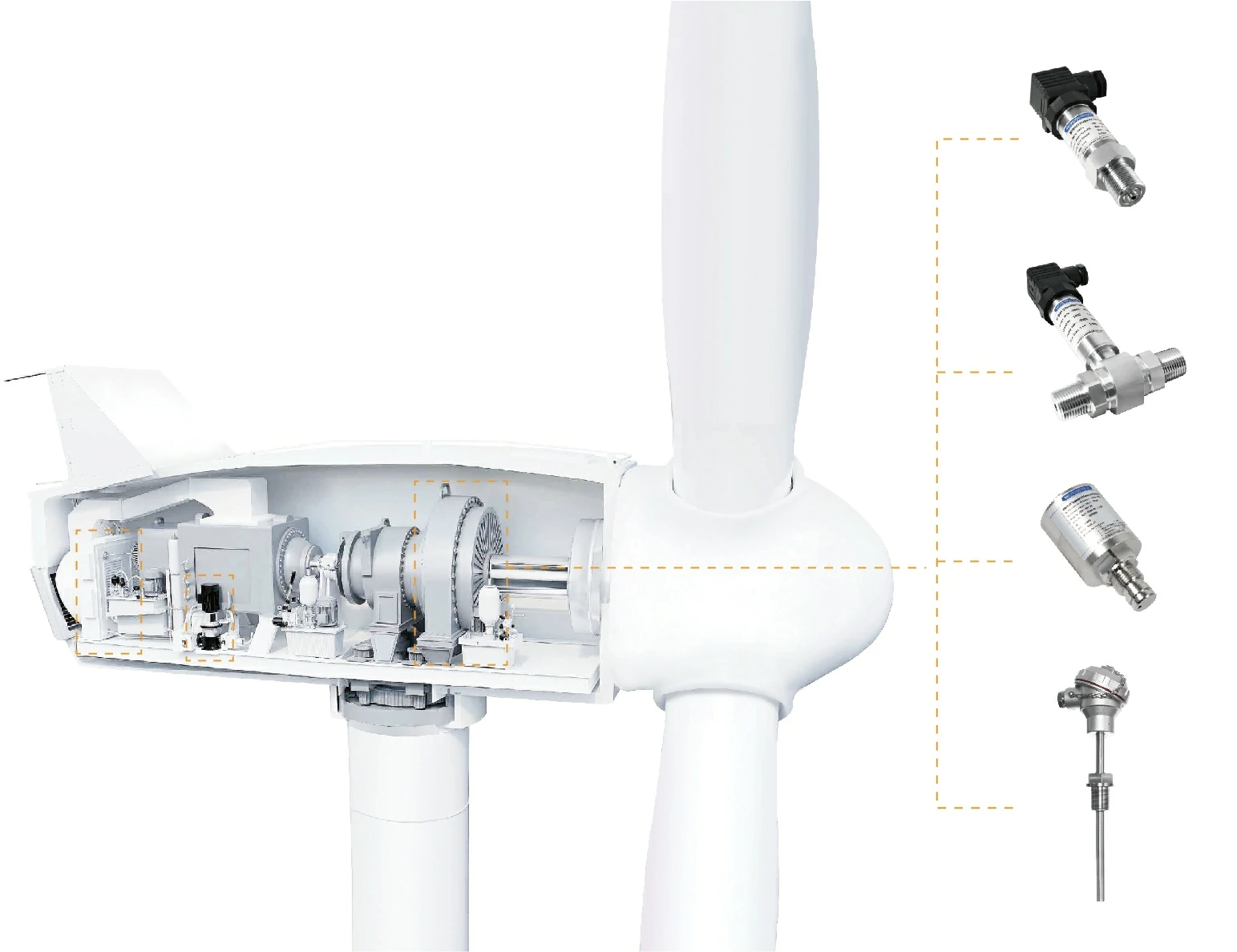

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...

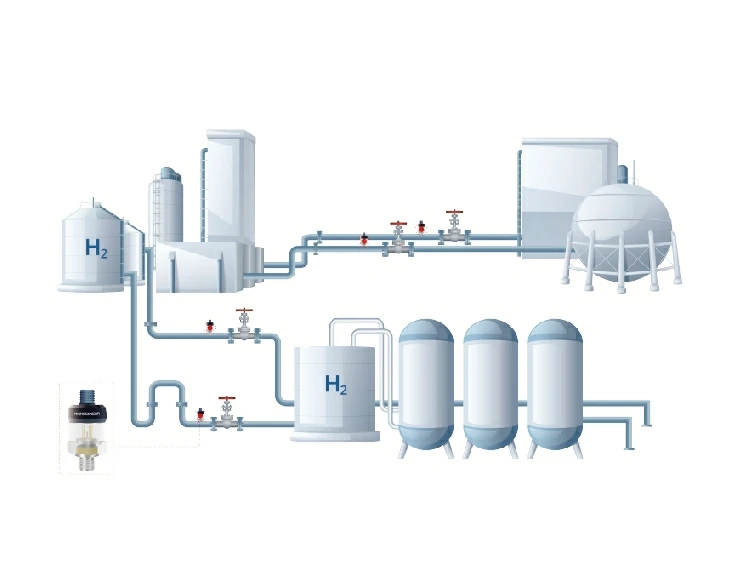

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...

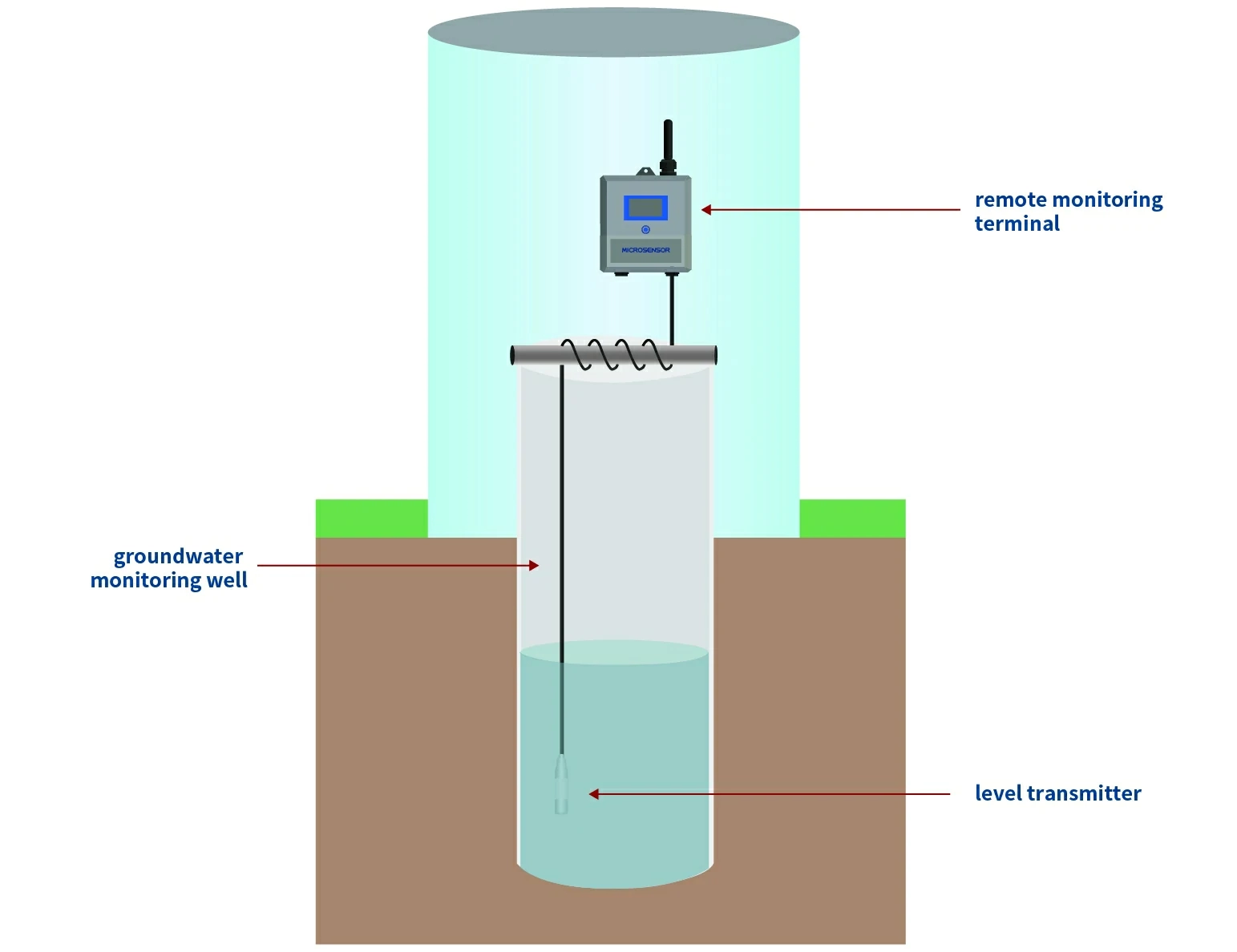

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...