Flush Diaphragm Pressure Sensor

M20x1.5, R1/2, G1/2

0bar~1bar...35bar

Flush Diaphragm

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM280Ti

Used For

Seawater or Corrosive Media Measurement, Liquid Pressure System and Switch

Leave a MessageMPM280Ti Anti-corrosive Pressure Sensor is unique for strongly corrosive media or seawater measurement. Its anti-corrosive performance is far better than stainless steel. The corrosive media being measured encompass a range of corrosive factors, such as pitting, acid erosion, stress corrosion, alkaline substances, chlorides, chlorine compounds, nitric acid, and various other corrosive substances. It uses all titanium material in construction, TC4 housing material and TA1 diaphragm.

Features

• Pressure range: 0bar ~ 1.0bar…700bar

• Gauge, Absolute and Sealed gauge

• Constant current or Constant voltage power supply for option

• Isolated construction to measure various fluid media

• Φ19mm OEM pressure element

• Different metals with excellent corrosion resistance for option

• Tnegtive pressure measurement is available, the lowest to around -1bar

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 3kΩ~8kΩ

Image:

MPM280Ti Anti-corrosive Pressure Sensor is unique for strongly corrosive media or seawater measurement. Its anti-corrosive performance is far better than stainless steel. The corrosive media being measured encompass a range of corrosive factors, such as pitting, acid erosion, stress corrosion, alkaline substances, chlorides, chlorine compounds, nitric acid, and various other corrosive substances. It uses all titanium material in construction, TC4 housing material and TA1 diaphragm.

Features

• Pressure range: 0bar ~ 1.0bar…700bar

• Gauge, Absolute and Sealed gauge

• Constant current or Constant voltage power supply for option

• Isolated construction to measure various fluid media

• Φ19mm OEM pressure element

• Different metals with excellent corrosion resistance for option

• Tnegtive pressure measurement is available, the lowest to around -1bar

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 3kΩ~8kΩ

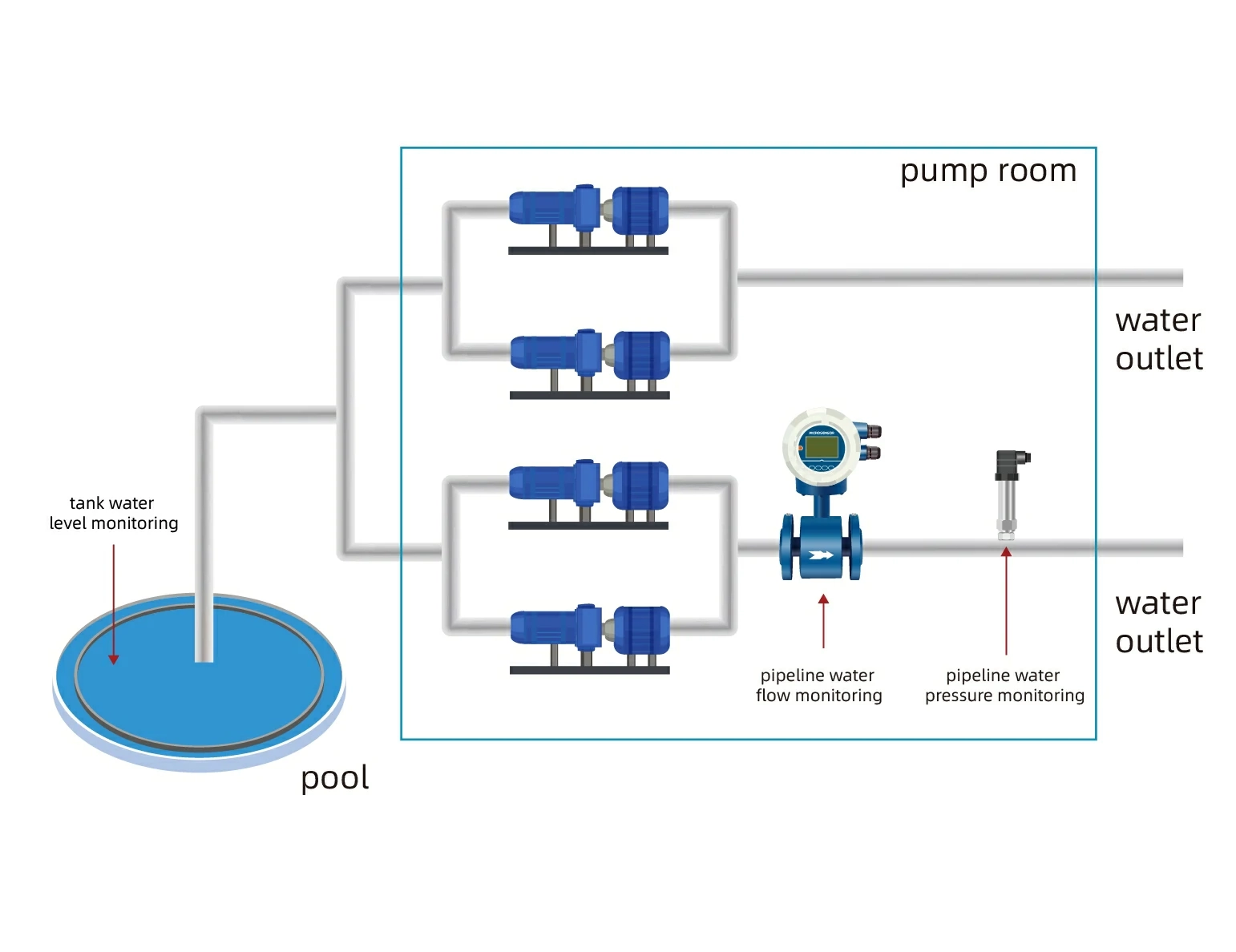

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

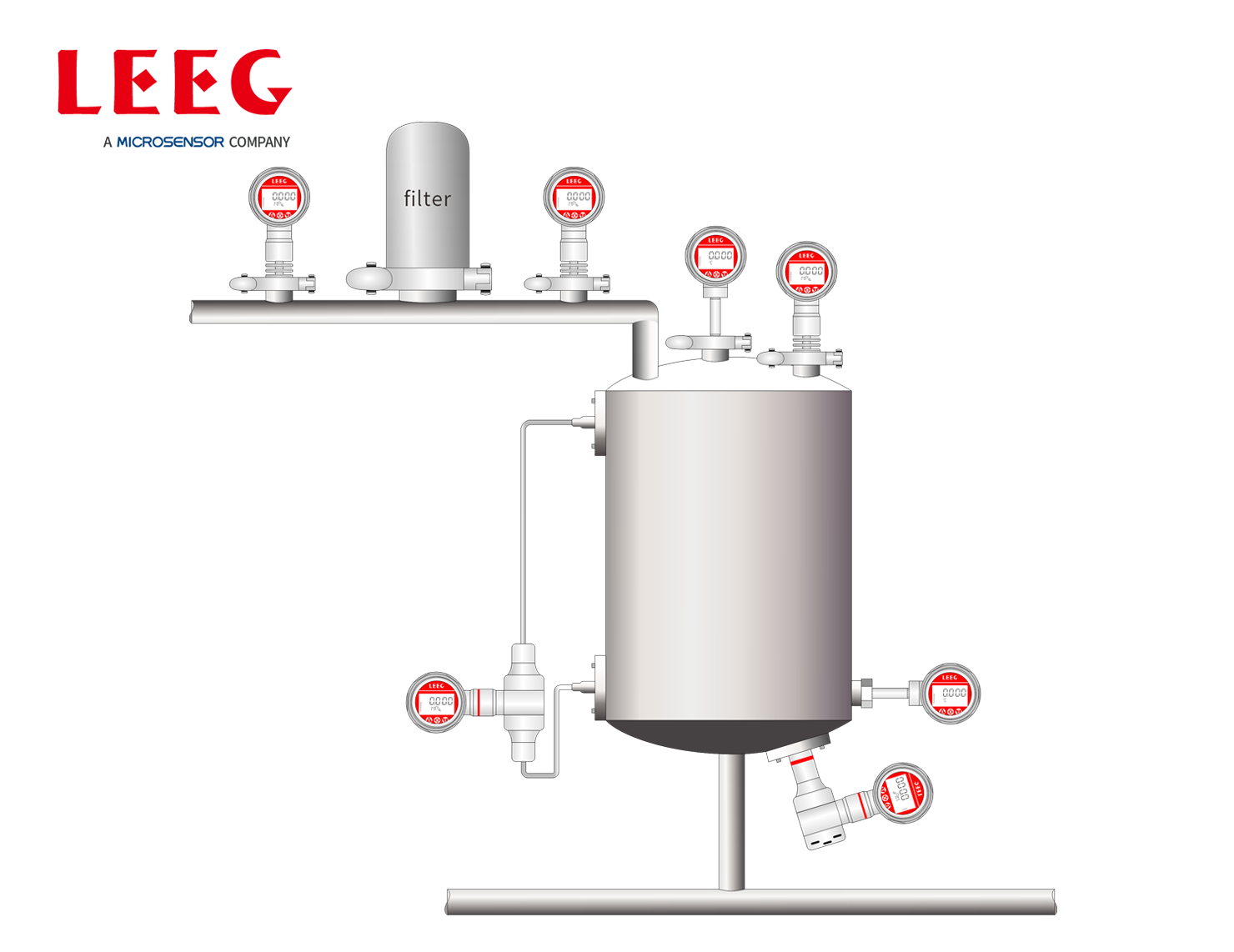

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...

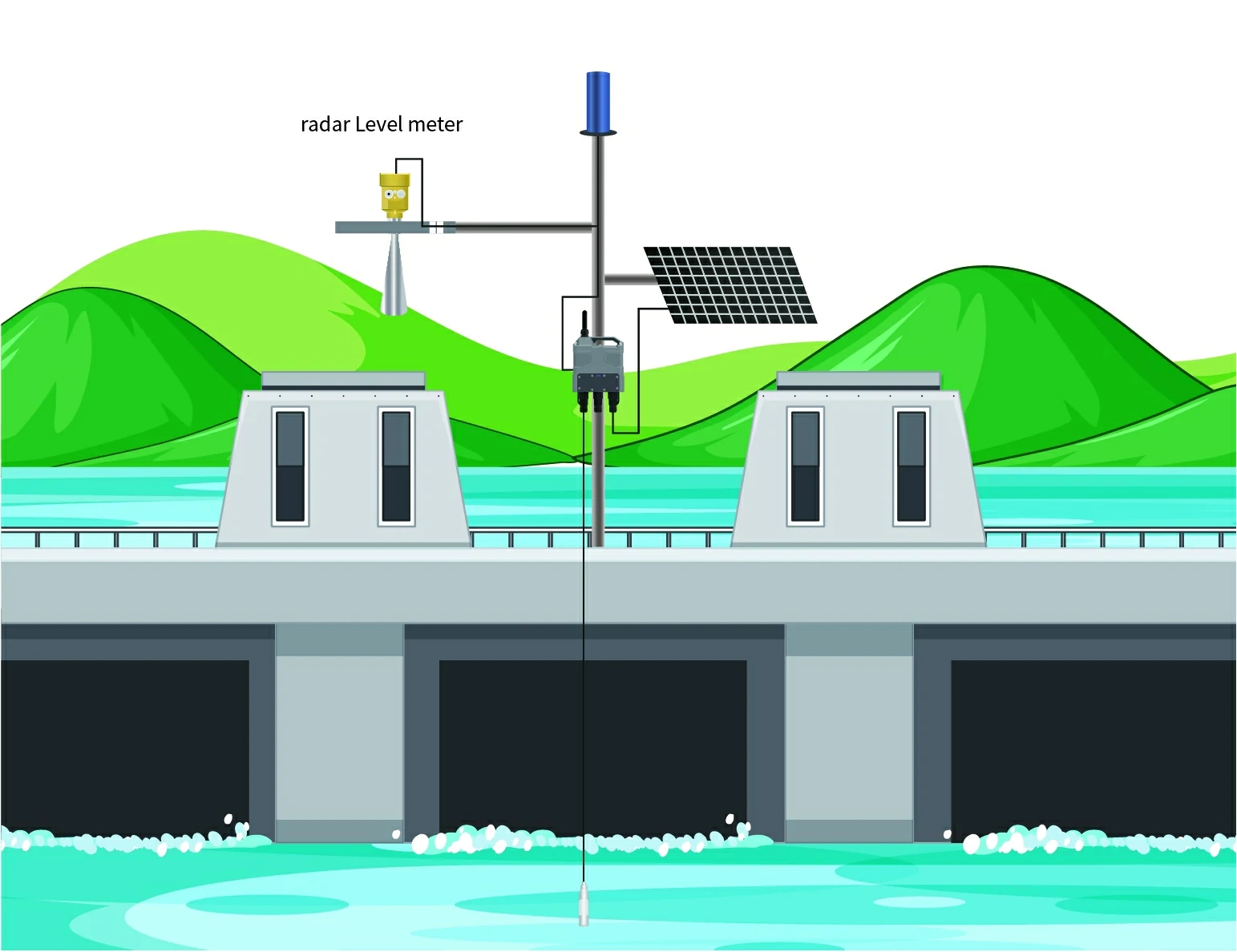

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

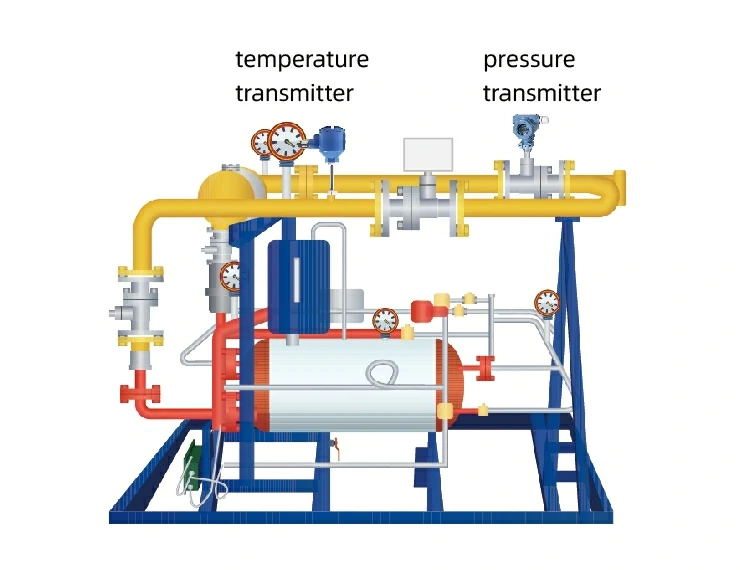

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...