Flush Diaphragm Pressure Sensor

M20x1.5, R1/2, G1/2

0bar~1bar...35bar

Flush Diaphragm

MPM280P

Used For

Industrial Process Control, Gas & Liquid Pressure Measurement, Refrigeration Equipment and Air

Leave a MessageThe MPM280P flush diaphragm pressure sensor is connected via male threads and clamps. Pressure ports are G1/2 male, R1/2 male, NPT1/2 male, M20 x 1.5 male, and DN25 clamps with FKM or silicon O-ring seals. The product has an isolated structure and can measure the respective fluid medium.

Features

• Pressure range: 0bar ~ 0.35bar…350bar

• Gauge, Absolute and Sealed gauge

• Constant current or Constant voltage power supply for option

• Thread connection pressure: 0bar~0.35bar…350bar

• Clamp connection pressure: 0bar~0.35bar~35bar

• Hygienic structure optional(Ra<0.4μm)

• Tnegtive pressure measurement is available, the lowest to around -1bar

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 2.5kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulation resistor: 100MΩ@100V DC

• Overpressure: 2 times FS

Image:

The MPM280P flush diaphragm pressure sensor is connected via male threads and clamps. Pressure ports are G1/2 male, R1/2 male, NPT1/2 male, M20 x 1.5 male, and DN25 clamps with FKM or silicon O-ring seals. The product has an isolated structure and can measure the respective fluid medium.

Features

• Pressure range: 0bar ~ 0.35bar…350bar

• Gauge, Absolute and Sealed gauge

• Constant current or Constant voltage power supply for option

• Thread connection pressure: 0bar~0.35bar…350bar

• Clamp connection pressure: 0bar~0.35bar~35bar

• Hygienic structure optional(Ra<0.4μm)

• Tnegtive pressure measurement is available, the lowest to around -1bar

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: φ0.5mm Kovar pin or 100mm silicon rubber flexible wires

• Common mode voltage output: 50% of input (typ.)

• Input impedance: 2.5kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulation resistor: 100MΩ@100V DC

• Overpressure: 2 times FS

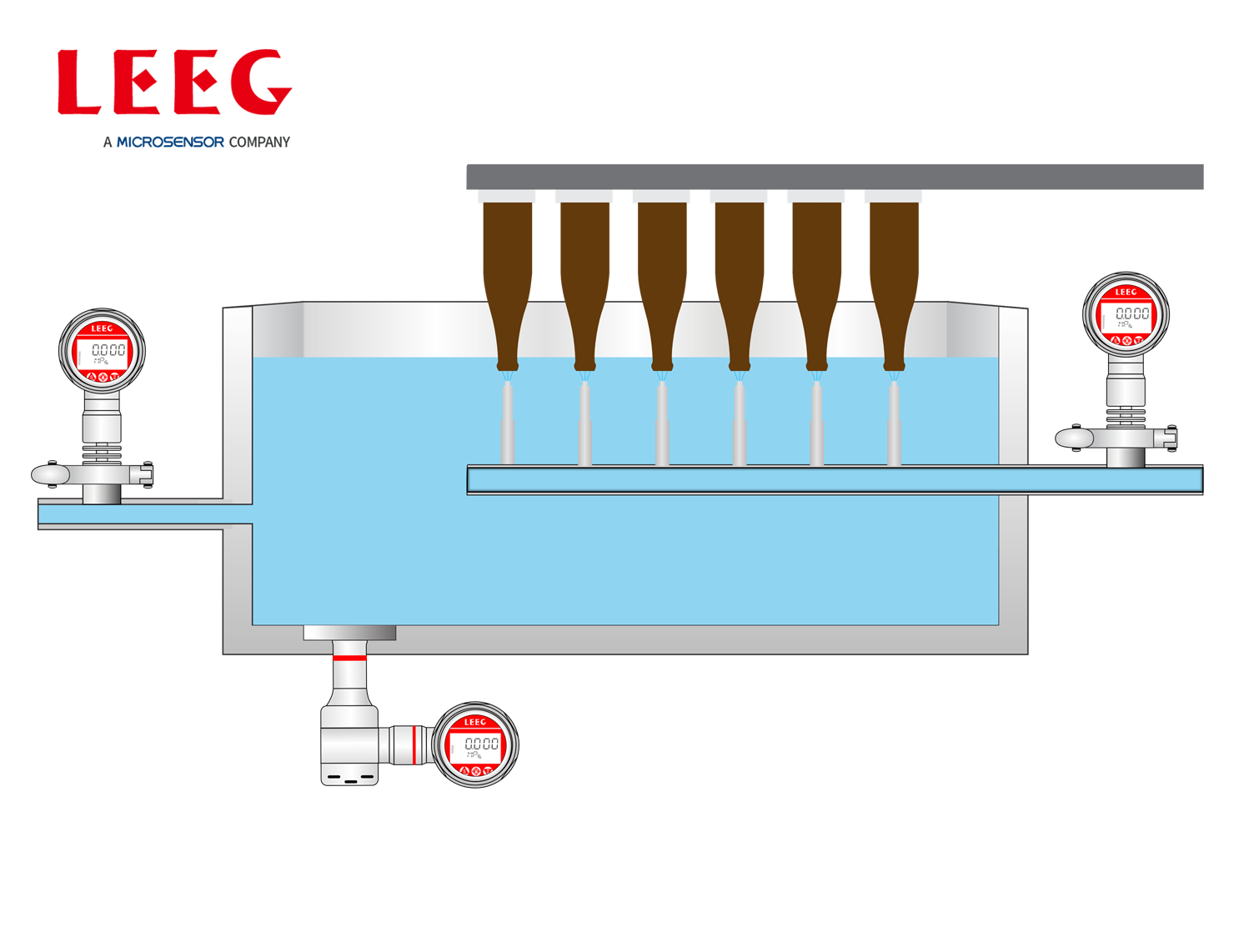

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

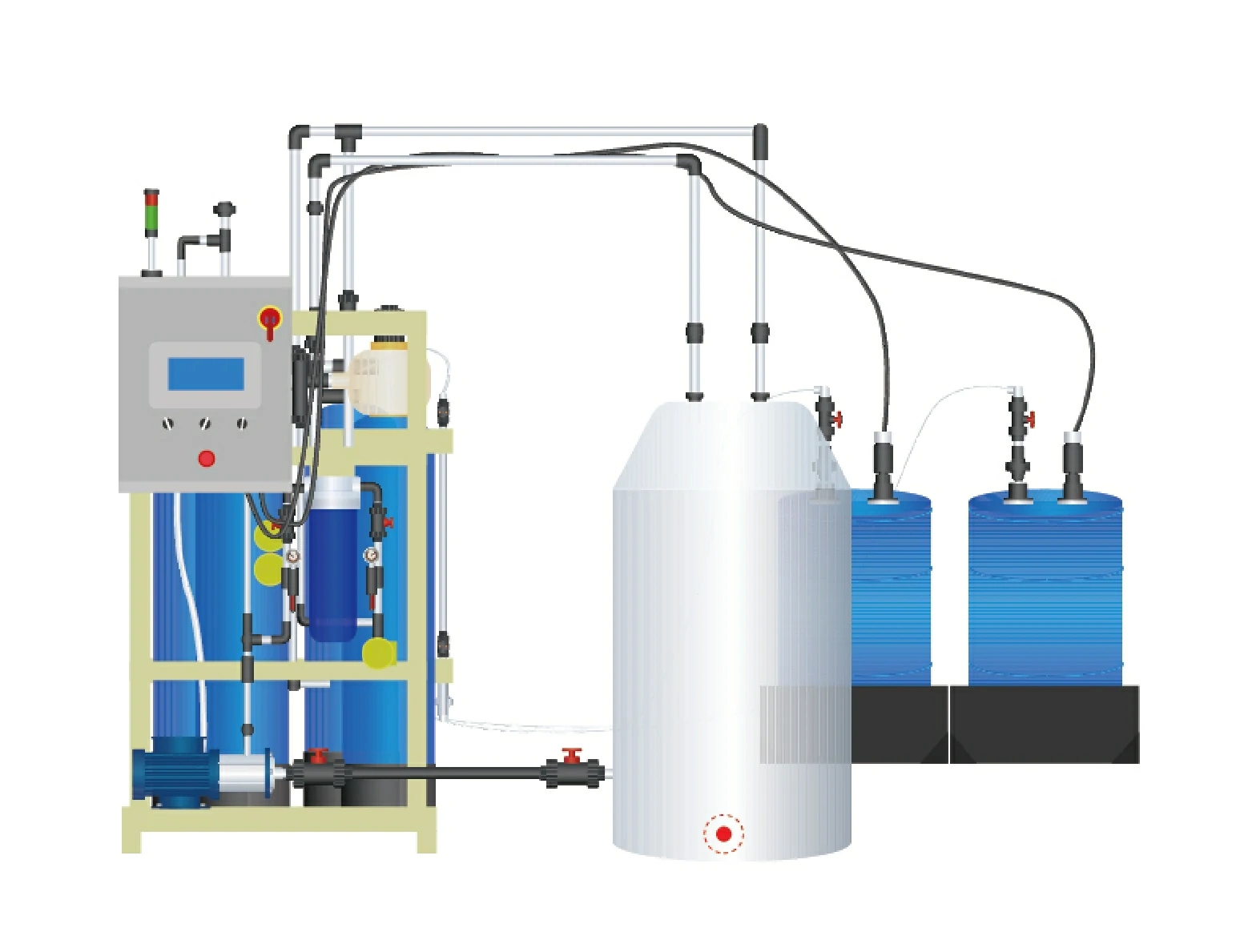

Deionized water is commonly used in industrial manufacturing cleaning processes. The target pressure values should be achieved during the production. It is necessary to monitor the pressure of the inlet and outlet. Only no blockages or leaks ensure normal operation of the production process.

more info...

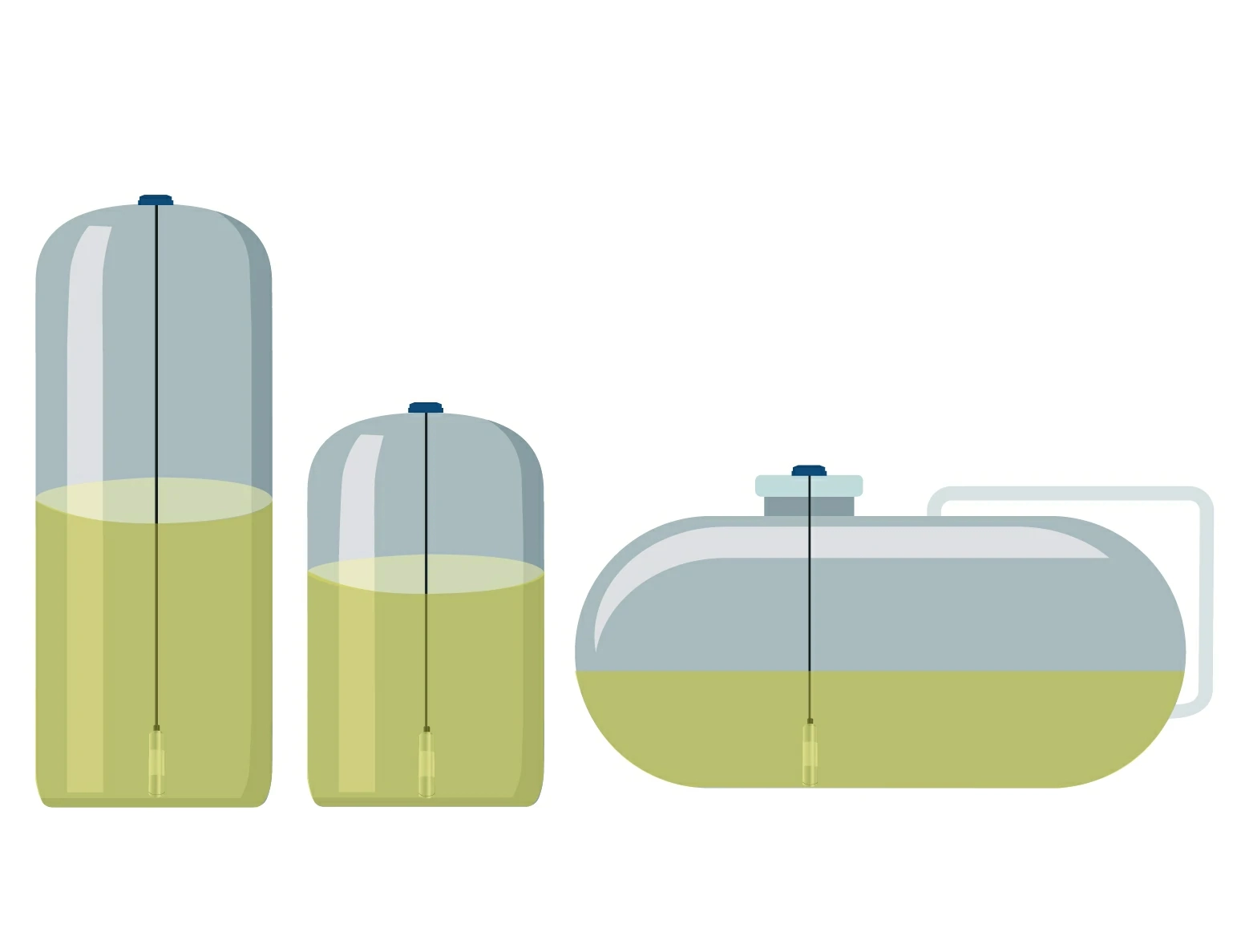

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...