Anti-corrosive Pressure Sensor

Φ19mm

-1bar...0bar~1bar…700bar

Tantalum Diaphragm

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM280HH

Used For

Gas & Liquid Pressure Measurement, Pressure Meter Refrigeration Equipment & Air Conditioner

Leave a MessageMPM280HH anti-corrosive pressure sensor is packaged in a Hastelloy C276 diaphragm and Hastelloy C276 housing, which are resistant to corrosion from chemicals, saltwater, and other corrosive materials. Sealed by FKM O-ring,this anti-corrosive pressure sensor is suitable for measuring corrosive medium. Customized options include pressure ranges, output signals, and electrical and mechanical configurations to fit specific industrial conditions.

Feature

• Φ19mm pressure element

• Corrosive media measurement

• Customized for special scene application

Specification

• Pressure Range: -1.0bar~0bar~1bar…350bar

• Diameter: Φ19mm

• Media compatibility: gases or liquids compatible with construction material and FKM

• Diaphragm: Hastelloy C

• Housing: Hastelloy C

• Power supply: ≤2.0mA DC

Image:

MPM280HH anti-corrosive pressure sensor is packaged in a Hastelloy C276 diaphragm and Hastelloy C276 housing, which are resistant to corrosion from chemicals, saltwater, and other corrosive materials. Sealed by FKM O-ring,this anti-corrosive pressure sensor is suitable for measuring corrosive medium. Customized options include pressure ranges, output signals, and electrical and mechanical configurations to fit specific industrial conditions.

Feature

• Φ19mm pressure element

• Corrosive media measurement

• Customized for special scene application

Specification

• Pressure Range: -1.0bar~0bar~1bar…350bar

• Diameter: Φ19mm

• Media compatibility: gases or liquids compatible with construction material and FKM

• Diaphragm: Hastelloy C

• Housing: Hastelloy C

• Power supply: ≤2.0mA DC

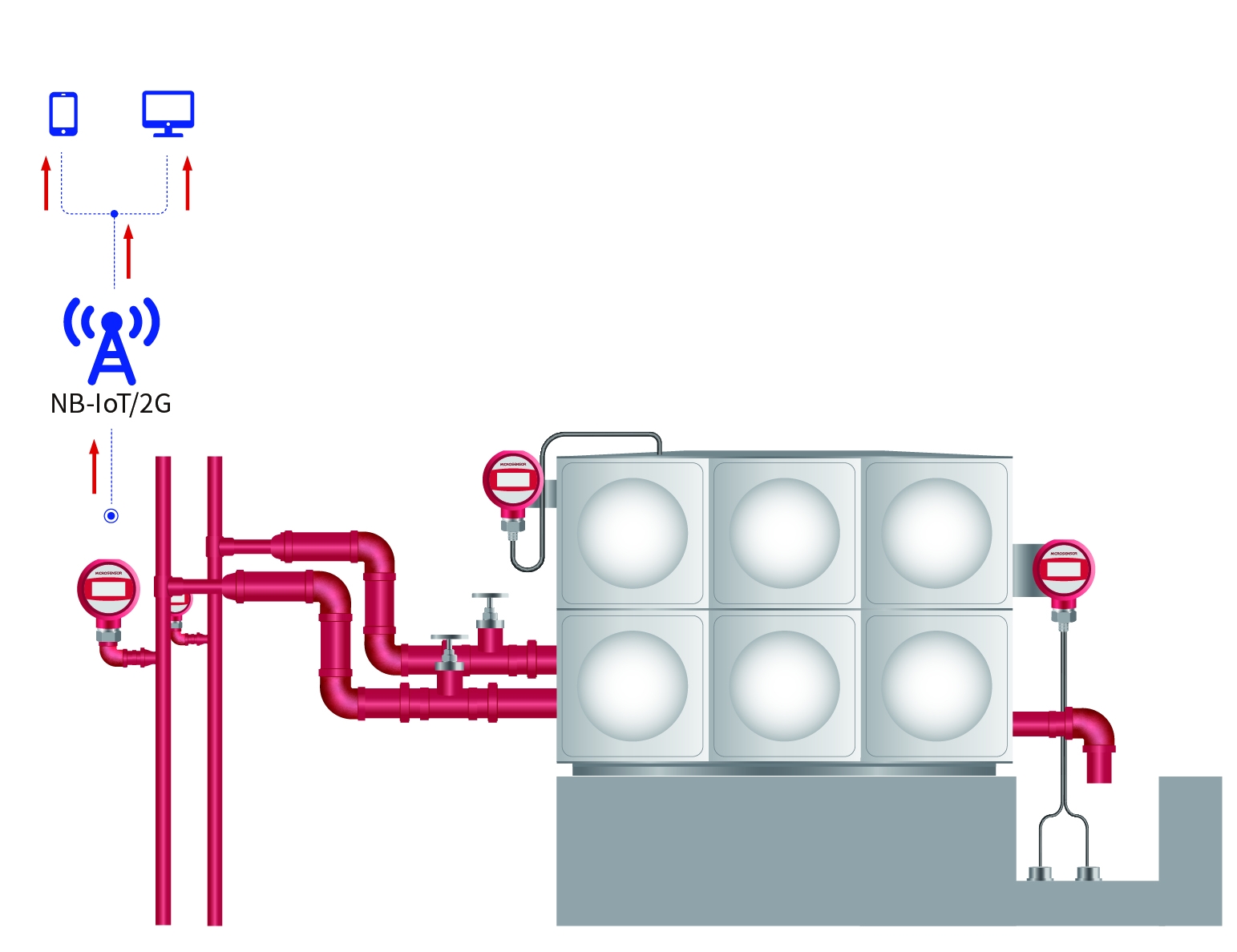

The normal operation of fire-fighting water pipeline plays an important role in safeguarding citizens' personal and property safety. Monitoring instruments are installed at each monitoring point of the fire protection pipeline to monitor pressure and level data in real time, so that when an error occurs, faults are located in time and alarms are given to facilitate staff maintenance and processing.

more info...

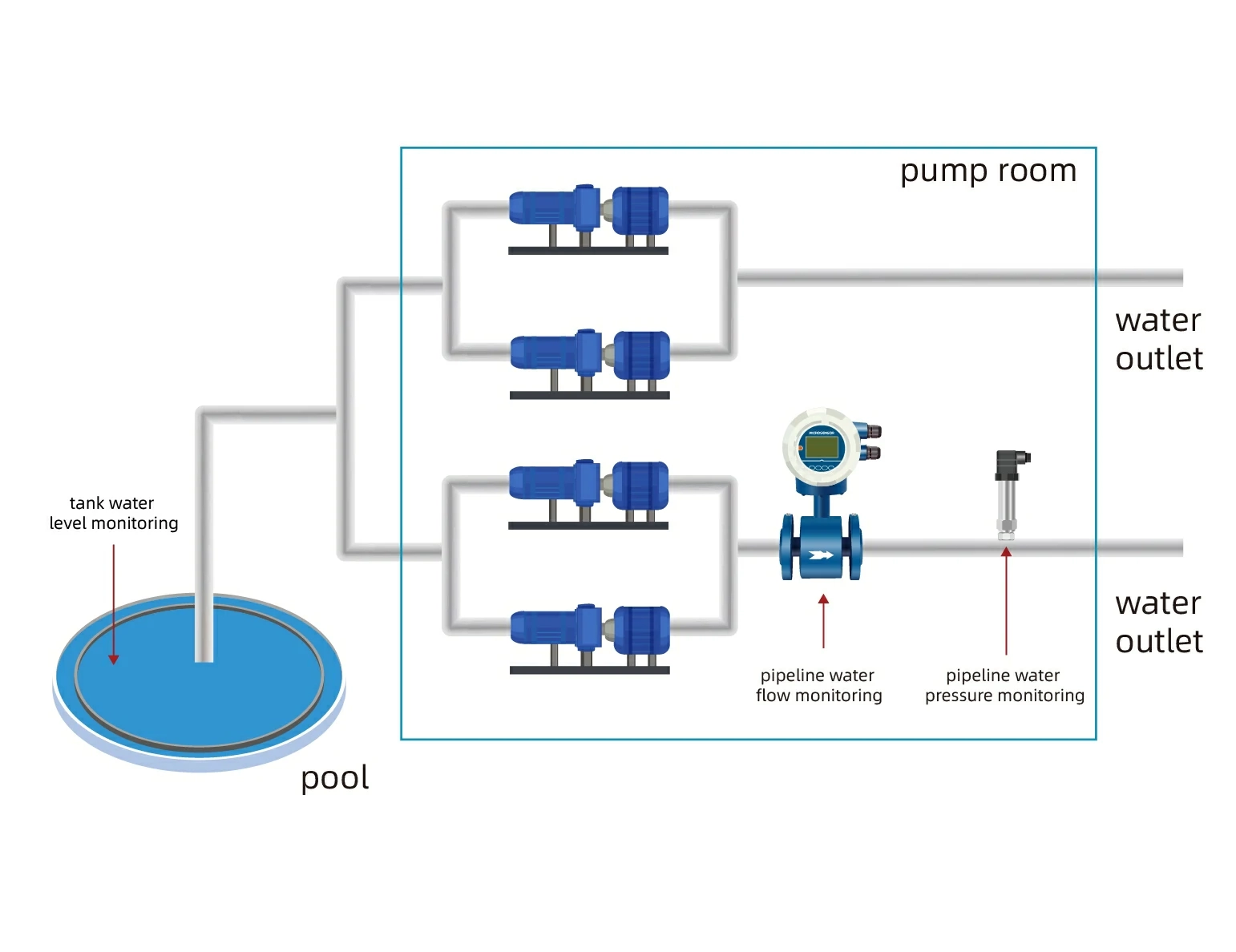

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

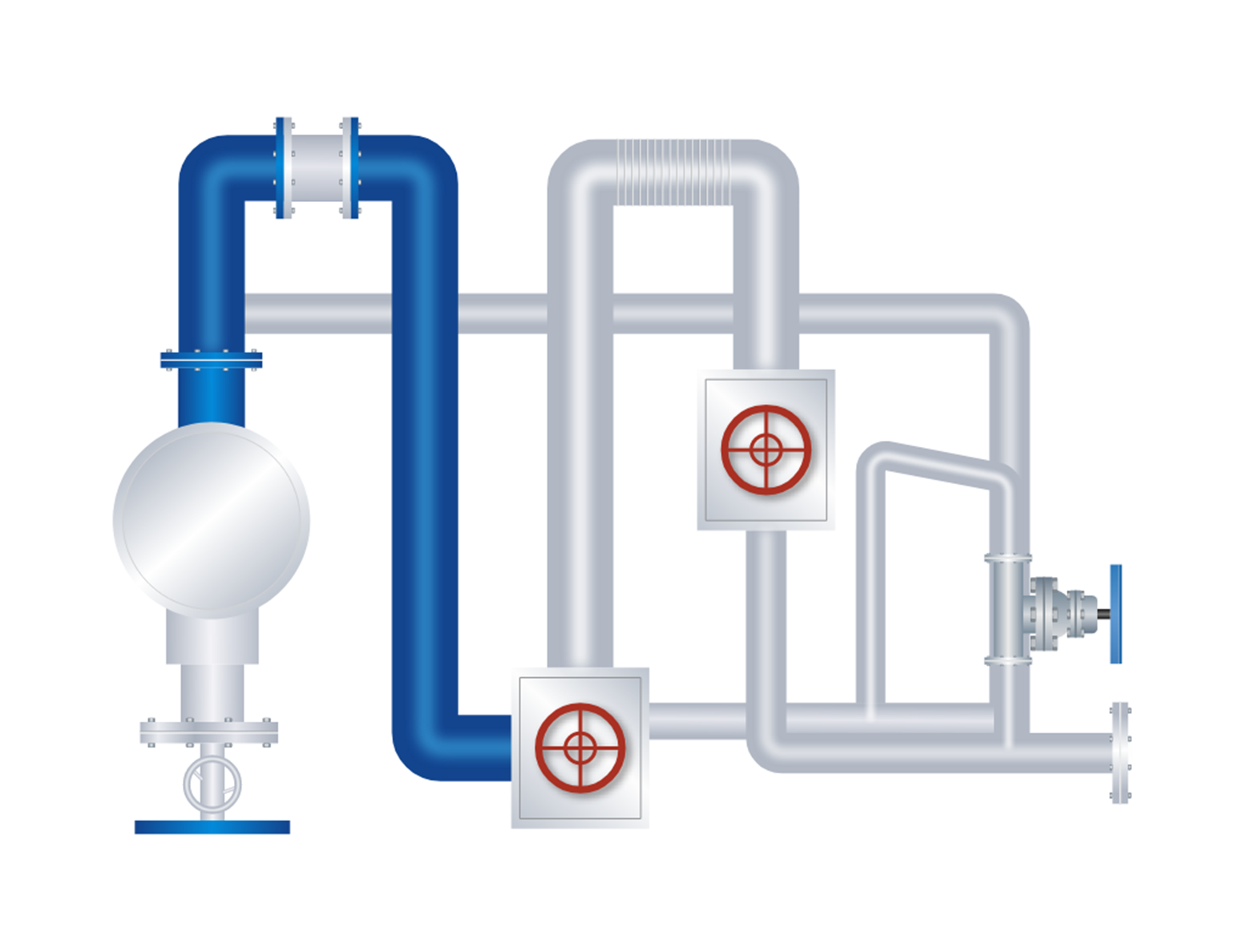

The paper machine's drying section employs steam-heated cylinders, with steam generated by a separate boiler and transported by pipelines. To ensure optimal steam supply, a differential pressure transmitter with an orifice plate is used to measure flow, allowing for accurate planning.

more info...

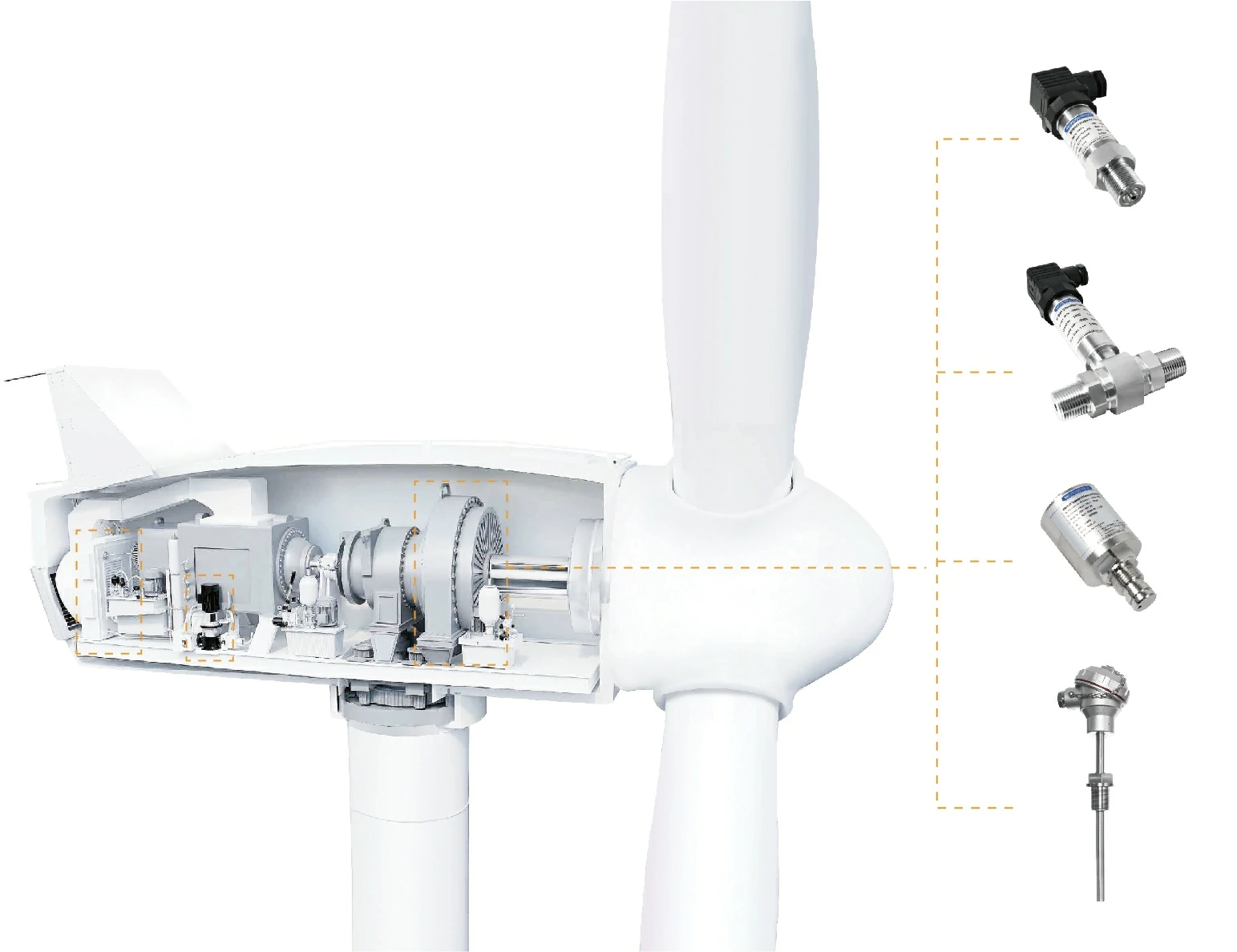

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...