In industrial automation and precision measurement, the stability and accuracy of the pressure sensor requires not only high-quality sensors, but also perfect matching of the sensing element and the circuit. Any minor circuit problem may cause measurement deviation and affect the performance of the overall system. Micro Sensor shares with you how to avoid common circuit problems and ensure your sensor performs well in various applications.

Q1: Calibration Circuit Power Supply Matching Problem: How to avoid the inaccuracy caused by mismatch?

A1: When you choose a diffused silicon pressure sensor, the power supply is crucial. Common power supply methods are constant current or constant voltage. You need to ensure that the sensor matches the circuit board power supply

for maximum performance. The wrong power supply may cause unstable output and thermal error over the standard range. The resistor compensation network of different power supply is different. The incorrect selection may make the temperature drift compensation function invalid.

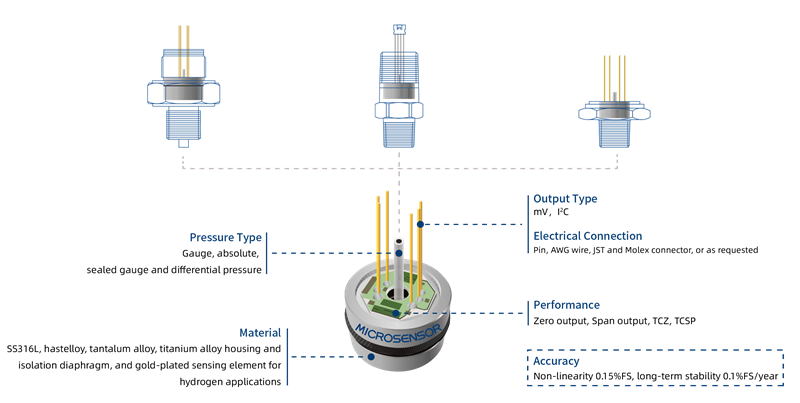

A suitable power supply guarantees performance. Micro Sensor's products provide a variety of power supply modes to meet different application requirements.

Q2: Power Supply Stability: How to ensure accurate measurement results?

A2: The output of the diffused silicon piezoresistive pressure sensor depends on the Wheatstone bridge structure. Therefore, the stability of the power supply directly affects the measurement values.The current fluctuation must be kept within ±0.0015mA under a constant current power supply; as for a constant voltage power supply, the voltage fluctuation should be less than ±0.005V.

Stable and reliable power supply ensures the stability and high accuracy of sensor output. Micro Sensor provide customize the power supply solution according to your needs.

Q3: The Problem of Constant Current Power Supply Load: How to avoid load distortion?

A3: For constant current powered pressure sensors, it is crucial to choose the right constant current source vaule.

If the constant current source is too high, it may cause distortion of op-amp under load. To avoid this problem, MicroSensor recommends that the constant current source value should be designed to be less than 800uA in a 5V power supply. Micro Sensor's technical team provide you with customized circuit design to ensure that your sensor system always runs in the best condition.

Q4: Signal Amplification Ratio: How to ensure the accuracy of signal processing?

A4: It's critical to choose the amplification ratio when digitizing millivolt signals. Too small ratio will result in substandard processed signals, while too large may cause the signal to enter the dead zone.

Micro Sensor provides optimized amplification circuit design to ensure that the signal can reach full scale during processing without over-amplification. In this way, you can obtain accurate and consistent measurement results.

Q5: The Problem of Filter Capacitor: How to balance filtering and response time?

A5: In order to reduce interference and noise, Micro Sensor adds filter capacitors on the circuit board. However, excessive filter capacitors may increase the sensor's response time. Especially, it will take several minutes to stabilize in specific applications.

Micro Sensor recommends that the filter capacitor should not exceed 10nF. The vaule ensure the best balance between stability and fast response. Micro Sensor's sensor is finely tuned and have a quick response. You can obtain timely and accurate data even in complex conditions.

Summary

You can ensure the long-term stability and high accuracy of the pressure sensor by selecting the correct power supply, ensuring power supply stability, and optimizing circuit design. Micro Sensor not only provide top performance, but also customized solutions according to your needs to ensure integration with your system.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD