High Pressure Range Pressure Sensor

Φ16.8x12mm

0bar~2bar…1000bar

-10~80℃ Compensated

MFE600

Used For

Coal, Textile, Environmental Protection, Water Conservancy Construction

Leave a MessageMFE600 Separated Electromagnetic Flowmeter is an instrument for volume flux measurement. Measurement accuracy is unaffected by changes in fluid density, viscosity, temperature, pressure, and conductivity. Low installation requirements. LCD display can show the integrated flow, flow rate, and other parameters.

Features

• No additional energy loss or jam, remarkable energy-saving.

• Good sensitivity, and good linearity.

• Low requirements for installation.

• Corrosion resistance and abrasive resistance.

• Parameter and cumulative values protection function.

Specifications

• Diameter: DN10 ~ DN800

• Excitation type Mode: Constant flux square wave excitation

• Installation: Integrated flanged, Separated Flanged

• Lining: Neoprene, Polyurethane rubber, PTFE, F46

• Electrode Material: 316L, Hc, Hb, Titanium, Tantalum, Platinum iridium, Tungsten carbide

Image:

MFE600 Separated Electromagnetic Flowmeter is an instrument for volume flux measurement. Measurement accuracy is unaffected by changes in fluid density, viscosity, temperature, pressure, and conductivity. Low installation requirements. LCD display can show the integrated flow, flow rate, and other parameters.

Features

• No additional energy loss or jam, remarkable energy-saving.

• Good sensitivity, and good linearity.

• Low requirements for installation.

• Corrosion resistance and abrasive resistance.

• Parameter and cumulative values protection function.

Specifications

• Diameter: DN10 ~ DN800

• Excitation type Mode: Constant flux square wave excitation

• Installation: Integrated flanged, Separated Flanged

• Lining: Neoprene, Polyurethane rubber, PTFE, F46

• Electrode Material: 316L, Hc, Hb, Titanium, Tantalum, Platinum iridium, Tungsten carbide

Range:0.1Bar~1000Bar

4~20mA DC

High Temperature 0~150℃ G31(General) Or Customized

High stability piezoresistive sensor die

Isolated construction, applicable to measuring various fluid

Range: 0bar~0.35bar... 35bar

Display: 4 digit 0.56 inch 14-segment LED

Output: 4~20mA DC, 0~10V DC

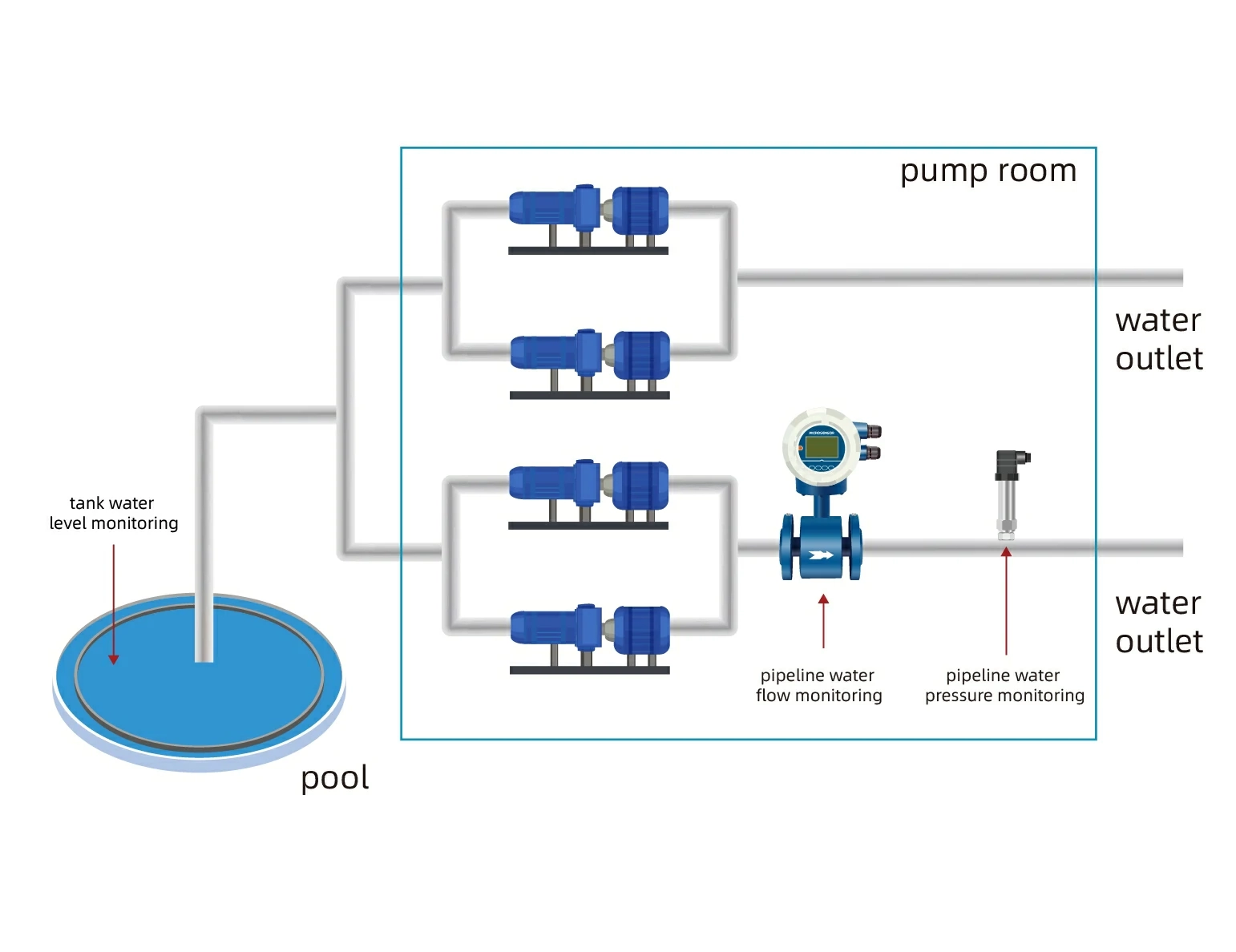

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

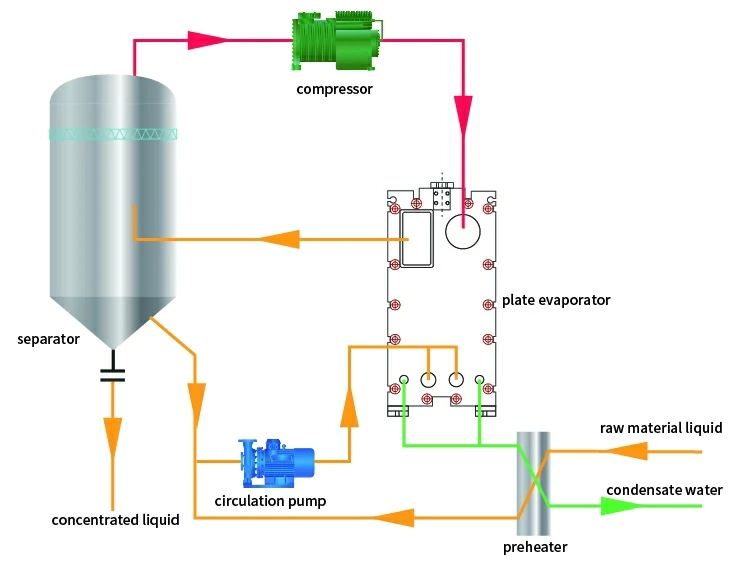

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

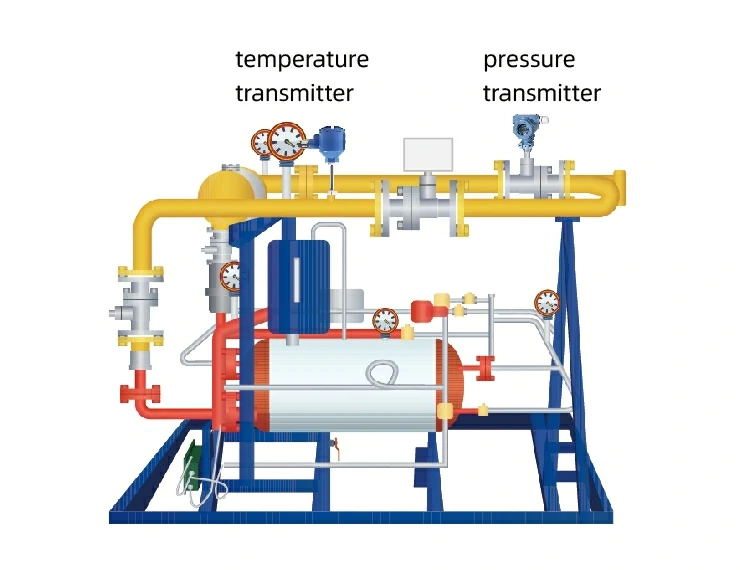

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...

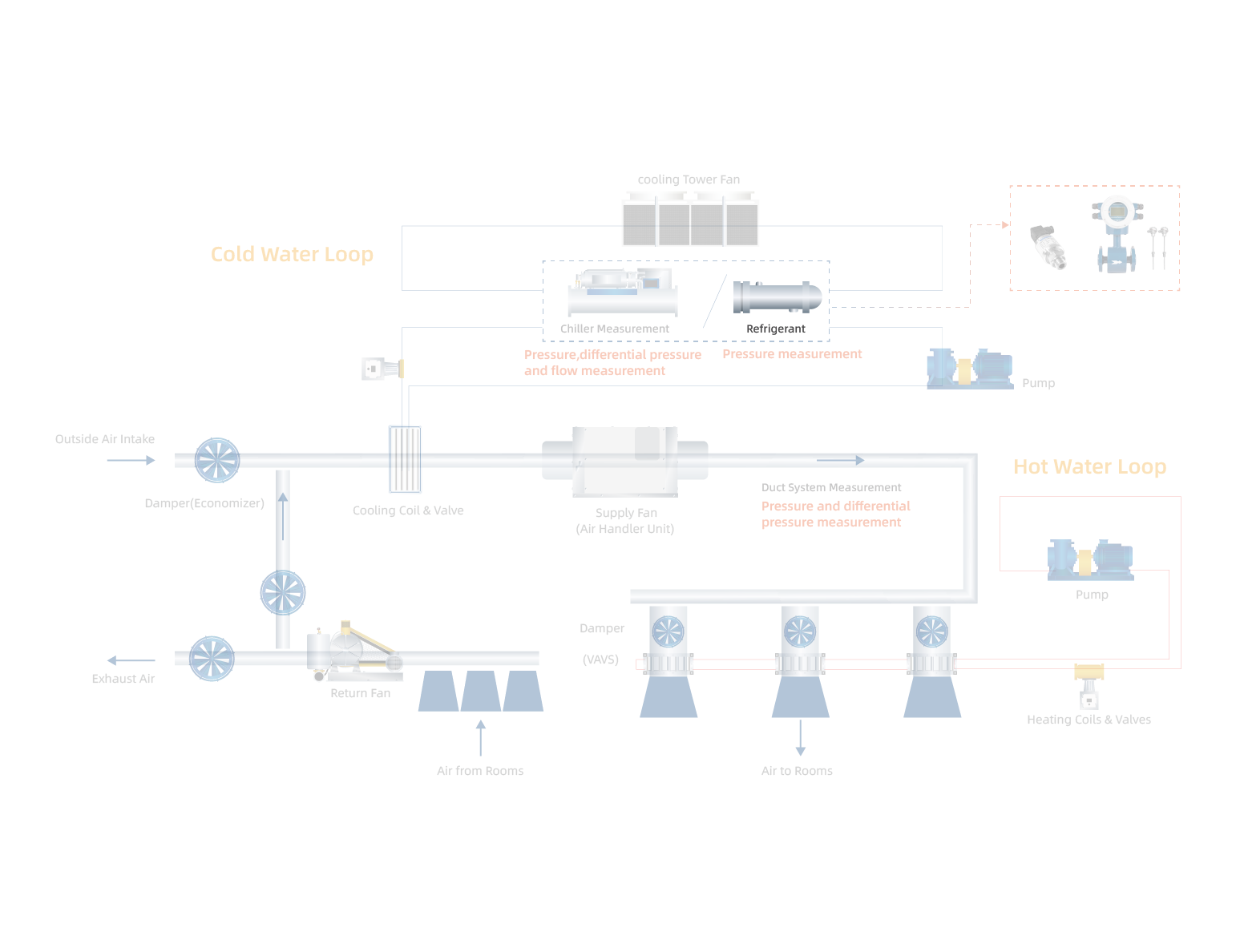

In HVAC systems, measuring the pressure of refrigerants is critical. Pressure transmitters monitor the refrigerant's pressure to ensure it operates within safe limits, preventing leaks and system failures. Accurate pressure measurement enhances system efficiency, ensures optimal cooling performance, and maintains safety by detecting potential issues early

more info...