Analog Output Pressure Transmitter

0bar~0.1bar...400bar

Accuracy: ±0.5%FS

Output Signal: 4-20m ADC

MDM4881

Used For

Pressure Detection on Industrial Equipment; Level Alarm

Leave a MessageThe MDM4881 Differential Pressure Transmitting Controller uses the international standard ARM processing chip and is an advanced digital pressure switch. The MDM4881 supports measurement, response and control of up to 5 relays. The display is easy to read and has multiple installation methods. This switch has peak recording and action delay functions. MDM4881 is the first choice for remote pressure measurement and control such as equipment pressure detection and water level alarm.

Feature

• Support 5-relay + 1 -analog output

• Provide 4 digit LED display

• Display pressure in real-time

Specification

• Range: 0kPa~0.35bar... 35bar

• Display: 4 digit 0.56 inch 14-segment LED display

• Operation Temp.(controller): -25℃ ~65℃

• Output Mode: 5 relays, normally open or closed contact

Image:

The MDM4881 Differential Pressure Transmitting Controller uses the international standard ARM processing chip and is an advanced digital pressure switch. The MDM4881 supports measurement, response and control of up to 5 relays. The display is easy to read and has multiple installation methods. This switch has peak recording and action delay functions. MDM4881 is the first choice for remote pressure measurement and control such as equipment pressure detection and water level alarm.

Feature

• Support 5-relay + 1 -analog output

• Provide 4 digit LED display

• Display pressure in real-time

Specification

• Range: 0kPa~0.35bar... 35bar

• Display: 4 digit 0.56 inch 14-segment LED display

• Operation Temp.(controller): -25℃ ~65℃

• Output Mode: 5 relays, normally open or closed contact

0bar~0.1bar...400bar

Accuracy: ±0.5%FS

Output Signal: 4-20m ADC

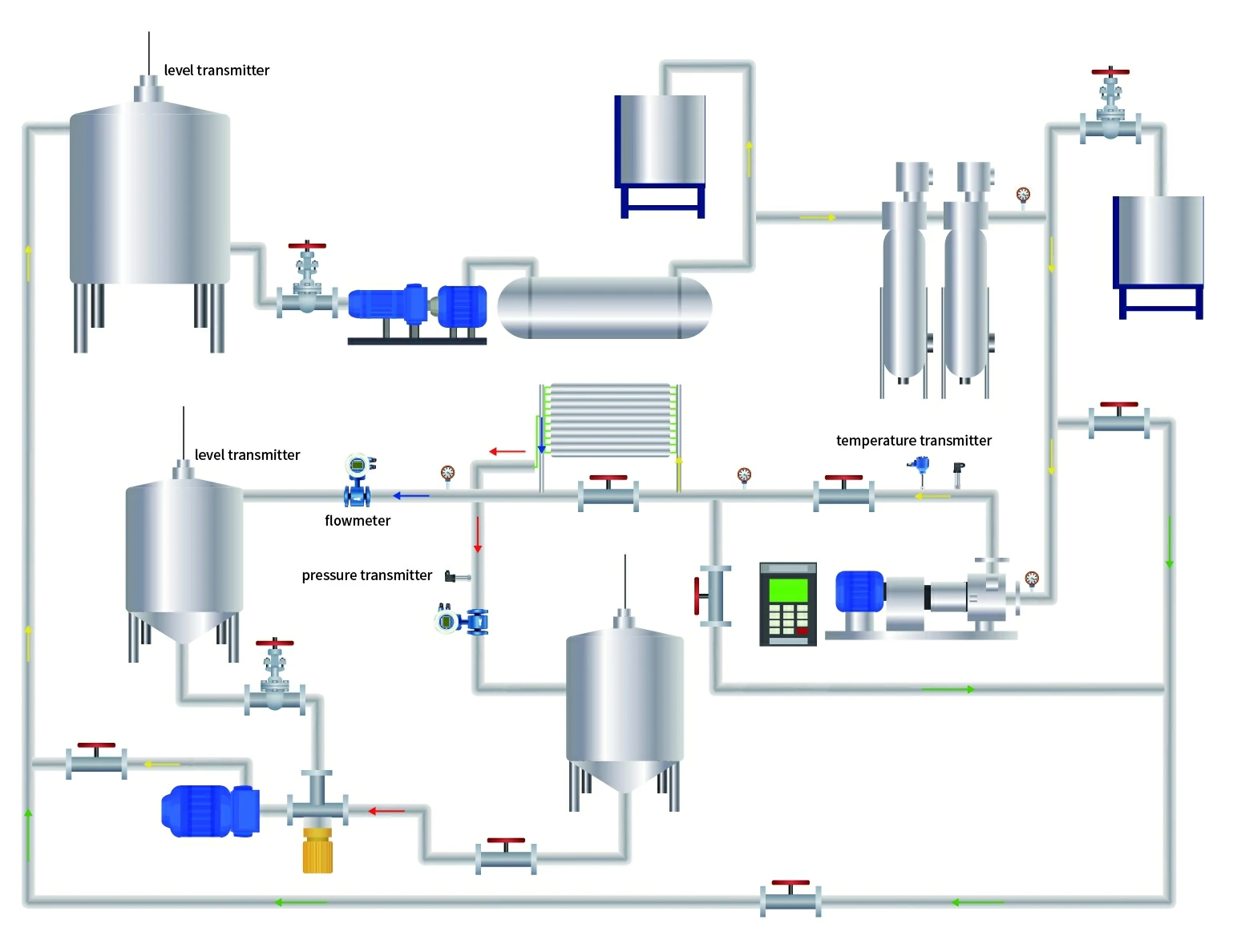

By monitoring the sewage flow, pipeline pressure and reservoir level, the efficiency of sewage treatment plant can be improved. At the same time, it can also facilitate operation and management, and achieve energy saving and automation control.

more info...

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...

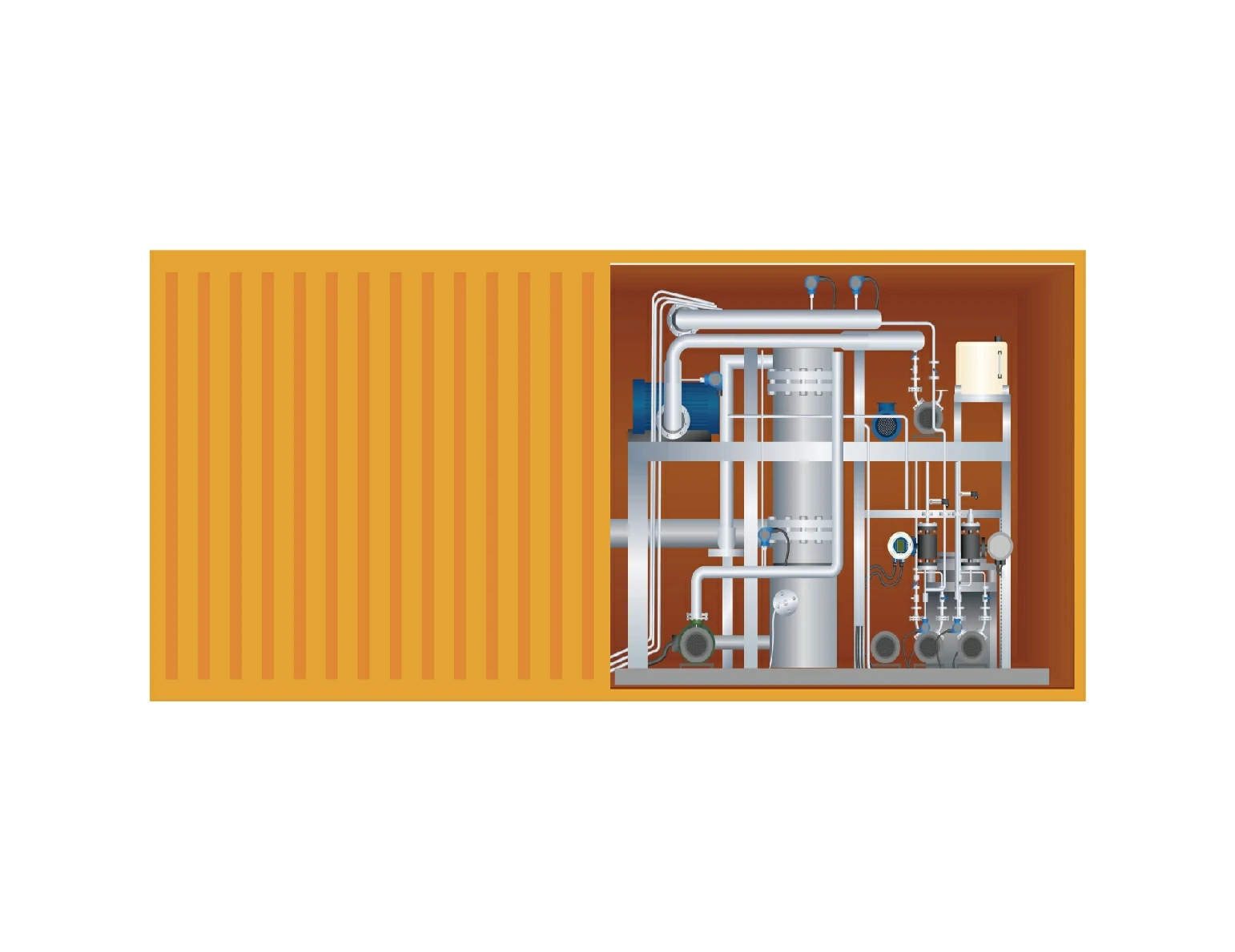

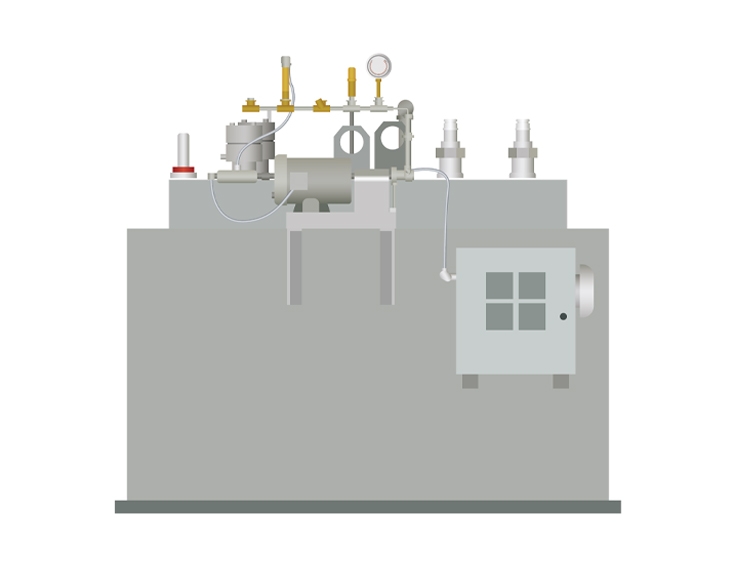

To ensure the fuel supply of the main engine, the separated heavy oil is first pumped to the settling tank, where the oil is heated and separated in the heating coil, and then purified by the oil separator before entering the daily tank through high-level overflow. The daily tank is directly connected to the main engine, boiler or other equipment, and the oil can be heated and used at any time.

more info...

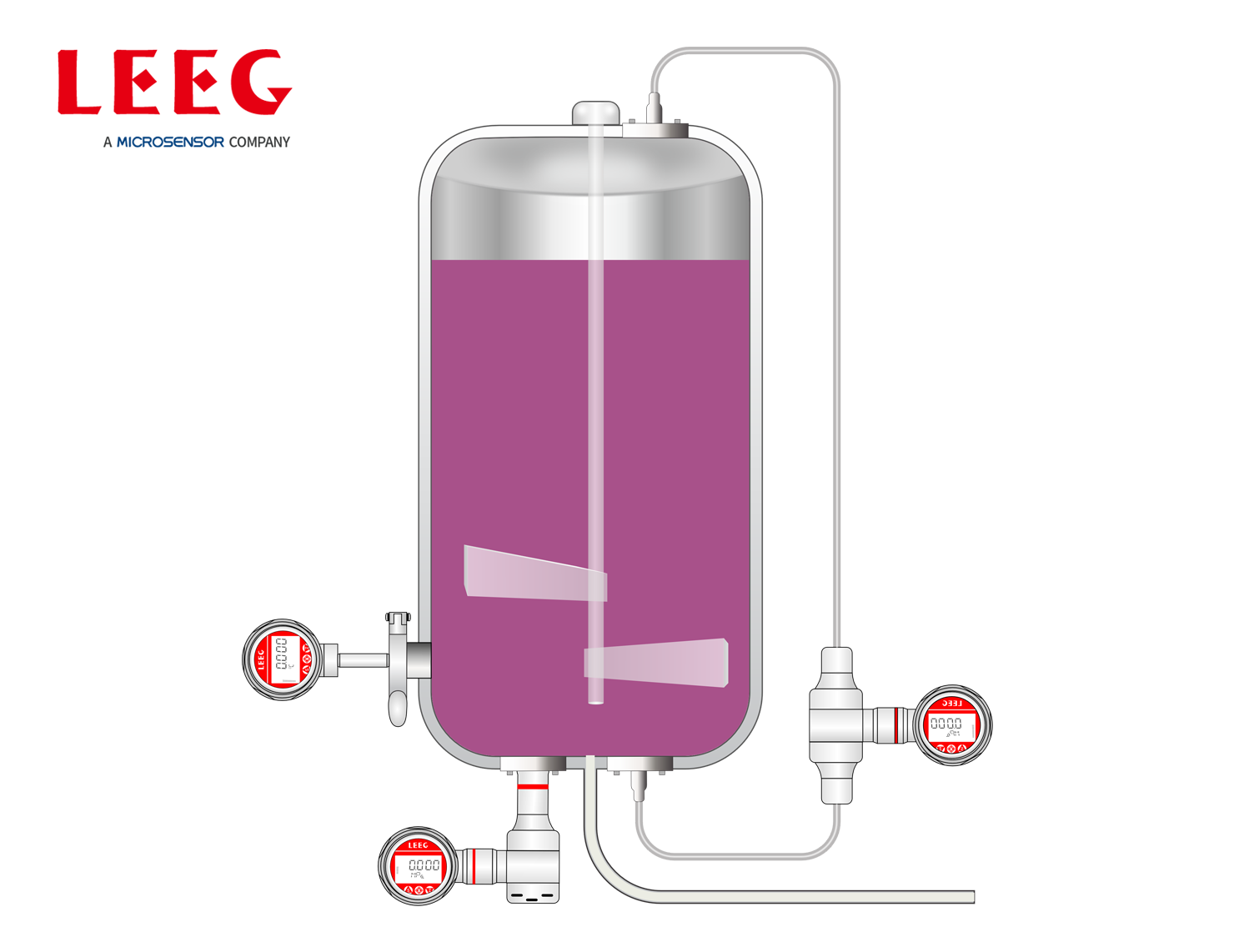

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...