Differential Pressure Transmitter

Output: mV

Accuracy: 0.25%FS

Max. static pressure 20MPa

MDM290

Used For

Differential Pressure Measurement, Pressure Calibrator, Ventura and Eddy-current Flow Meter

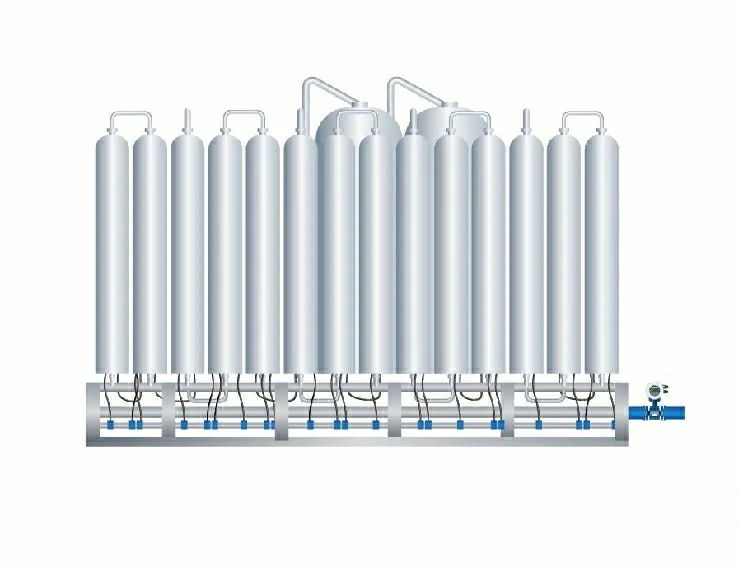

Leave a MessageThe MDM290 differential pressure sensor is piezoresistive and oil-filled type, isolated by a stainless steel corrugated diaphragm. As differential pressure sensor suppliers, Micro Sensor's pressure-sensitive components are assembled on advanced production lines, automatically tested and compensated by computer. The high and low-voltage ends are protected by isolation diaphragms. Both pressure chambers can be in contact with certain corrosive fluid media. The installation dimensions align with typical products, ensuring that the MDM290 sensor offers excellent interchangeability. MDM290 can be as an air differential pressure sensor for different gases. It is widely used in industrial process control and other fields to measure differential pressure.

Features

• Measuring range: 0.35Bar~35Bar

• Suitable for a variety of fluid media

• All 316L stainless steel material

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Pin: Silicon rubber flexible wire

• O-ring: FKM

Environment Condition

• Shock: No change at 10gRMS,(20 ~ 2000)Hz

• Impact: 100g, 11ms

• Media compatibility: The gas or liquid which is compatible with stainless steel and FKM

Image:

The MDM290 differential pressure sensor is piezoresistive and oil-filled type, isolated by a stainless steel corrugated diaphragm. As differential pressure sensor suppliers, Micro Sensor's pressure-sensitive components are assembled on advanced production lines, automatically tested and compensated by computer. The high and low-voltage ends are protected by isolation diaphragms. Both pressure chambers can be in contact with certain corrosive fluid media. The installation dimensions align with typical products, ensuring that the MDM290 sensor offers excellent interchangeability. MDM290 can be as an air differential pressure sensor for different gases. It is widely used in industrial process control and other fields to measure differential pressure.

Features

• Measuring range: 0.35Bar~35Bar

• Suitable for a variety of fluid media

• All 316L stainless steel material

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Pin: Silicon rubber flexible wire

• O-ring: FKM

Environment Condition

• Shock: No change at 10gRMS,(20 ~ 2000)Hz

• Impact: 100g, 11ms

• Media compatibility: The gas or liquid which is compatible with stainless steel and FKM

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...

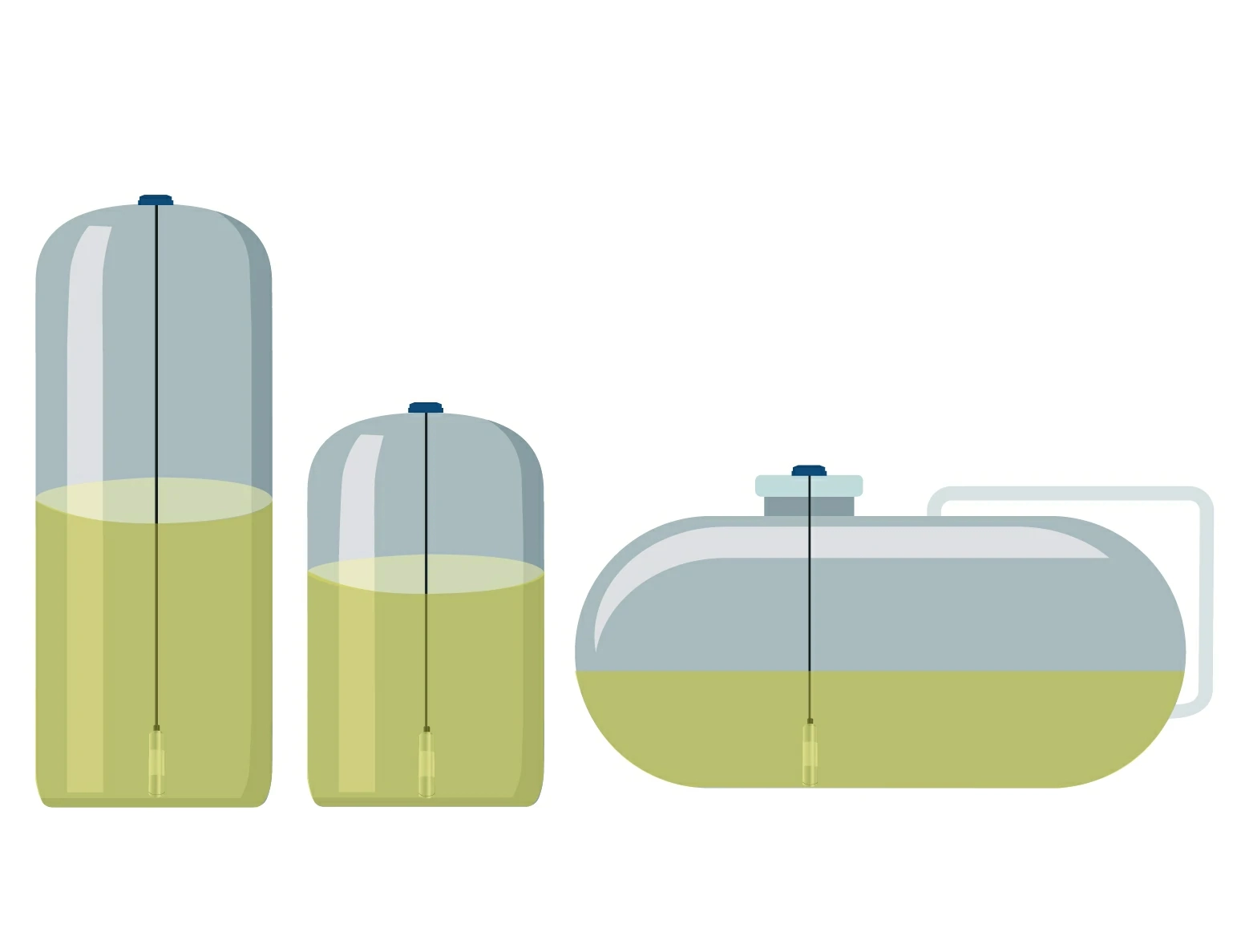

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

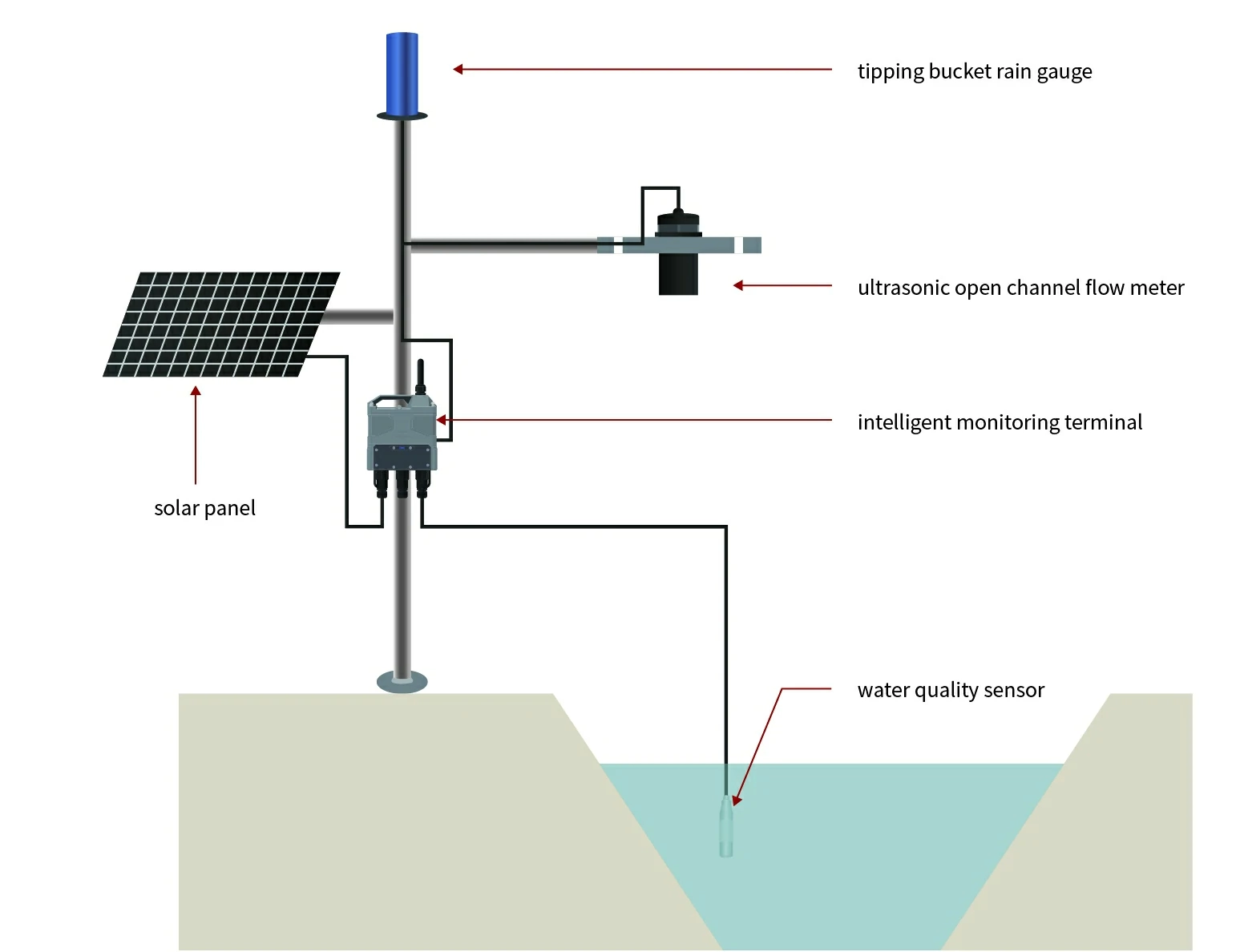

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...