Differential Pressure Transmitter

Output: mV

Accuracy: 0.25%FS

Max. static pressure 20MPa

MDM291

Used For

Industrial Process Control, Pressure Checking Meter, Pressure Calibrator

Leave a MessageMDM291 water differential pressure sensor is a fully welded sensor. The product has undergone automatic testing and temperature compensation process in the production process, so that the product has good temperature characteristics. MDM291 selects silicon chips with high precision and high stability. The measured differential pressure is transmitted to the sensitive chip through the pressure port, the isolation diaphragm and the filled silicone oil. This achieves a linear conversion of the differential pressure and output voltage signals. The high and low voltage ends of MDM291 are protected by isolation diaphragms. Both pressure chambers can be in contact with corrosive and conductive fluid media. The electrical connection and the high and low voltage terminals adopt threaded interface, which is convenient for assembly and installation.

Features

• Isolated structure without "O" type sealing ring

• All 316L stainless steel material

• High static pressure 20MPa

• Wide temperature compensation range 0℃~70℃

• Pressure port thread optional

Image:

MDM291 water differential pressure sensor is a fully welded sensor. The product has undergone automatic testing and temperature compensation process in the production process, so that the product has good temperature characteristics. MDM291 selects silicon chips with high precision and high stability. The measured differential pressure is transmitted to the sensitive chip through the pressure port, the isolation diaphragm and the filled silicone oil. This achieves a linear conversion of the differential pressure and output voltage signals. The high and low voltage ends of MDM291 are protected by isolation diaphragms. Both pressure chambers can be in contact with corrosive and conductive fluid media. The electrical connection and the high and low voltage terminals adopt threaded interface, which is convenient for assembly and installation.

Features

• Isolated structure without "O" type sealing ring

• All 316L stainless steel material

• High static pressure 20MPa

• Wide temperature compensation range 0℃~70℃

• Pressure port thread optional

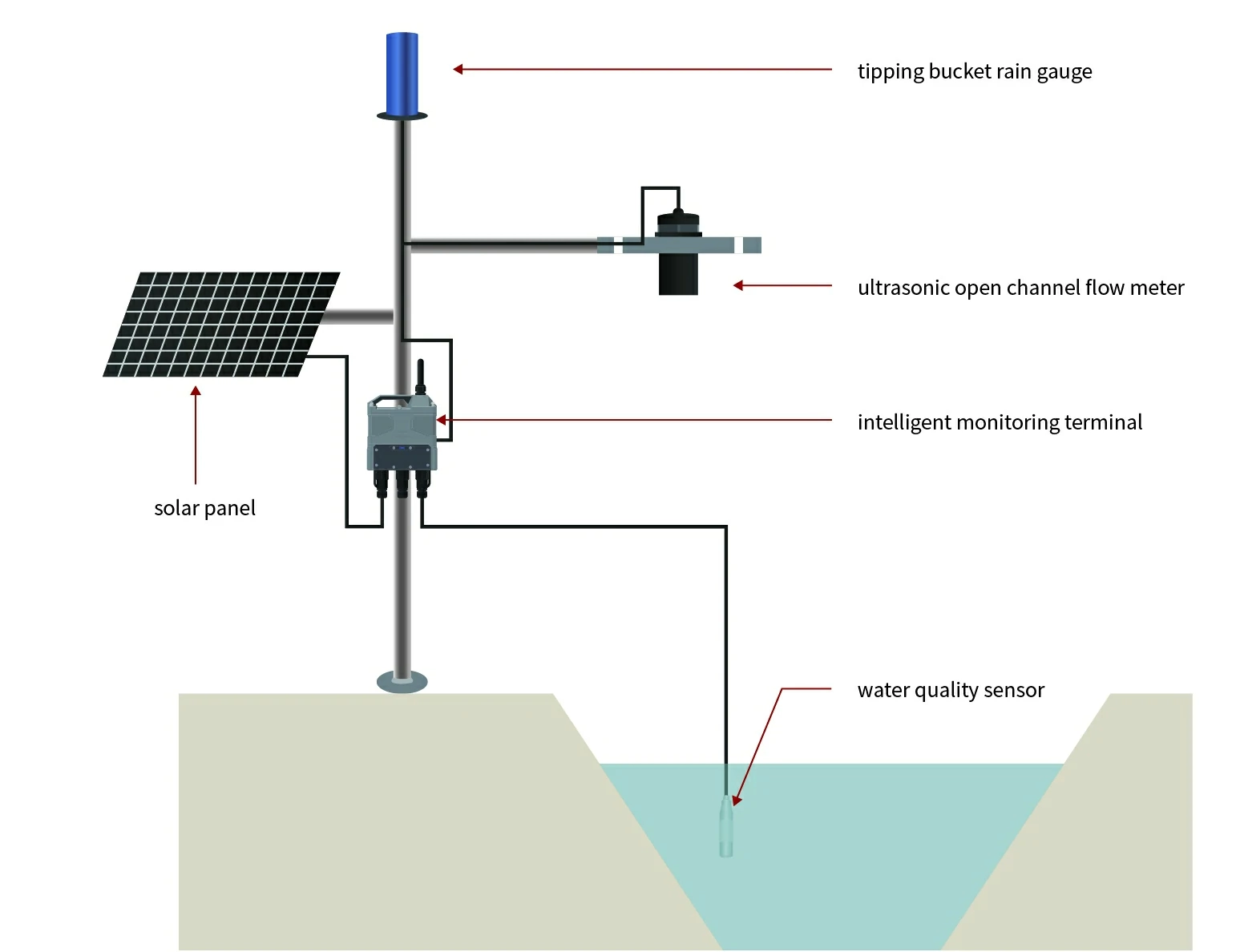

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...

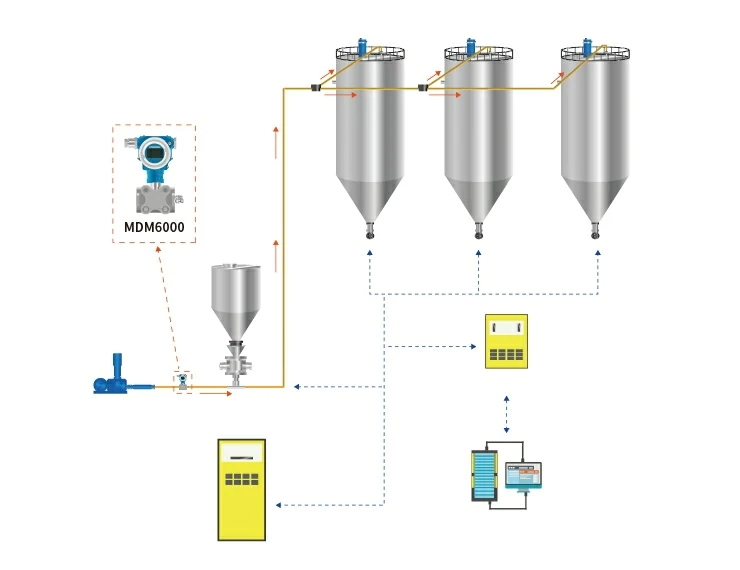

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

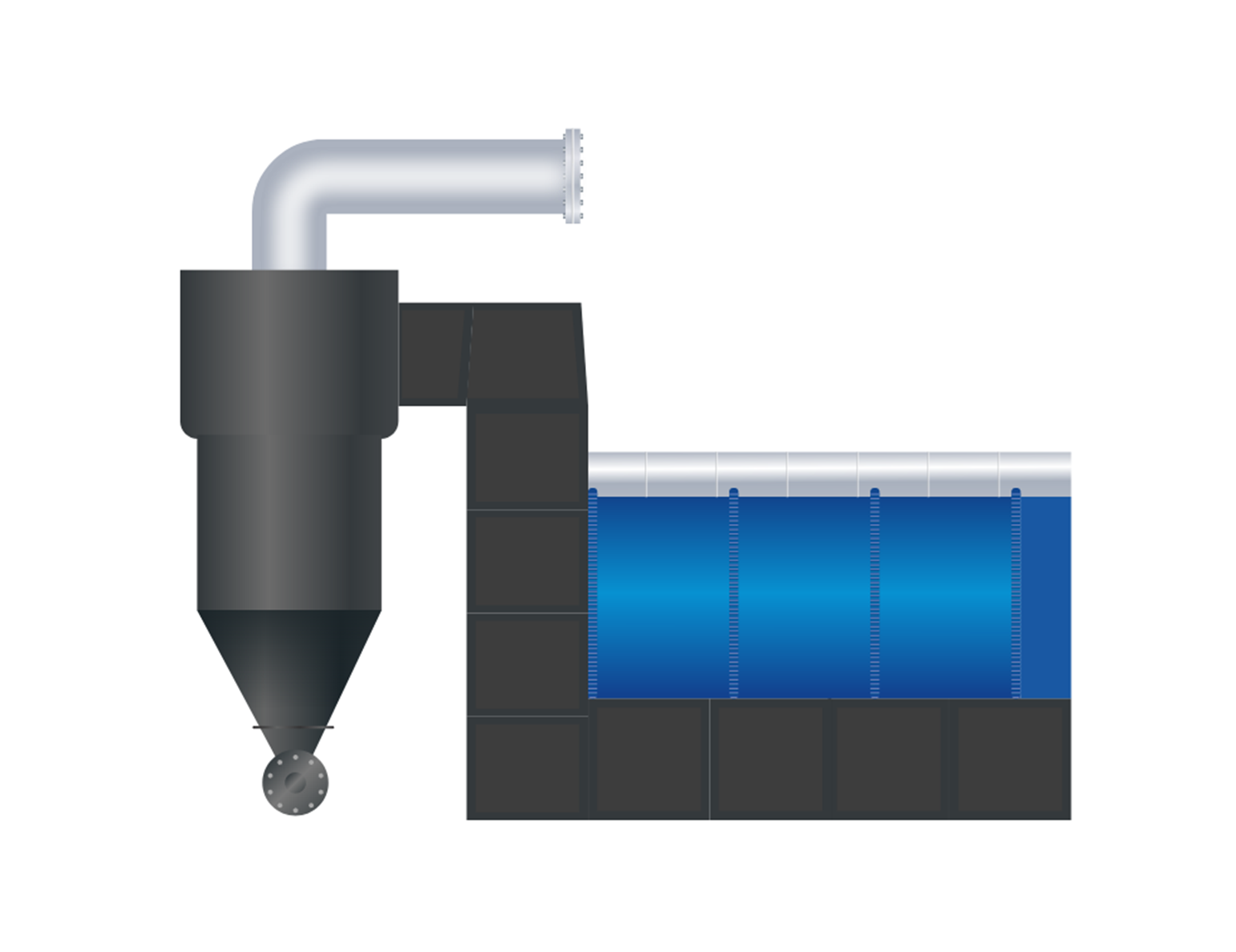

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...

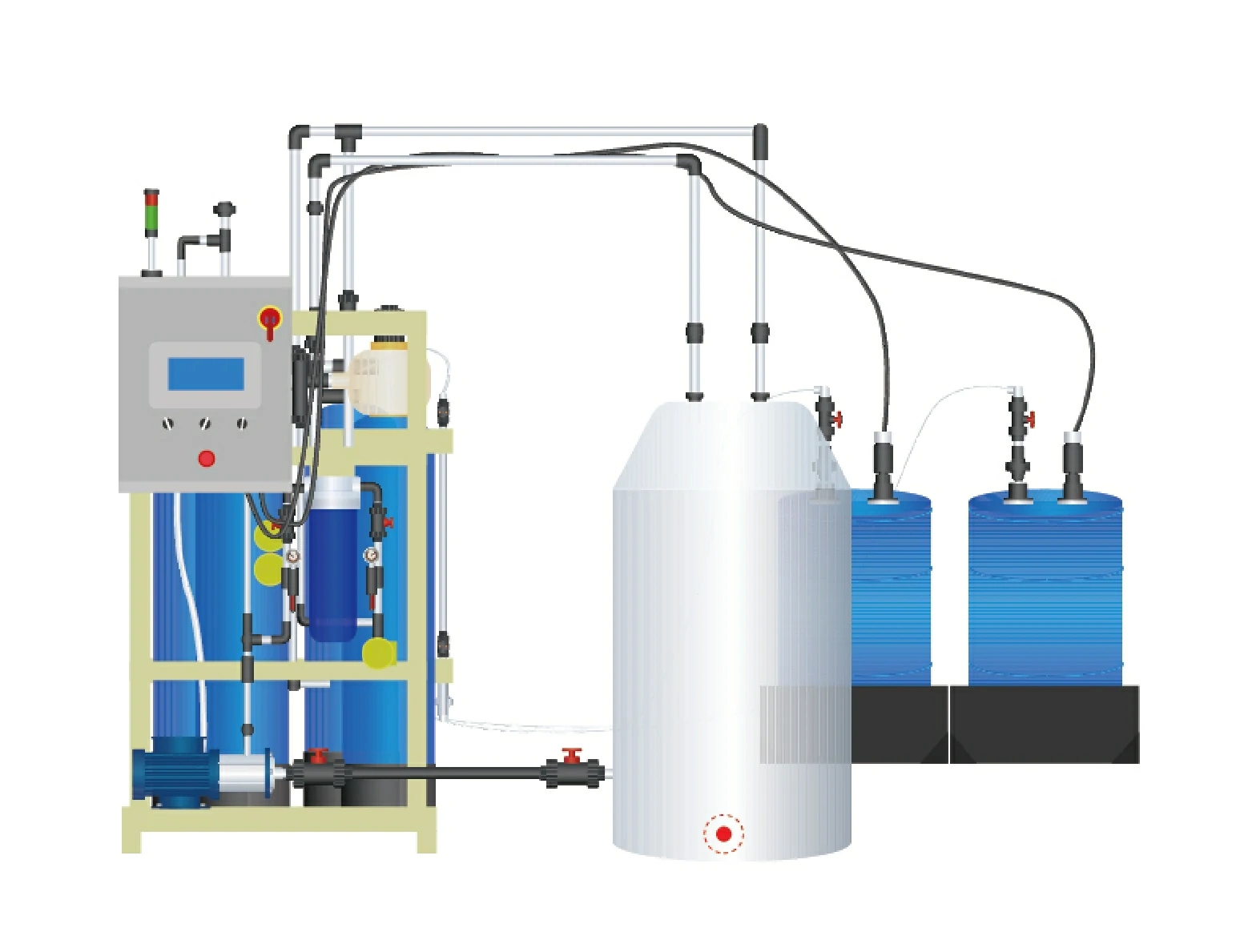

Deionized water is commonly used in industrial manufacturing cleaning processes. The target pressure values should be achieved during the production. It is necessary to monitor the pressure of the inlet and outlet. Only no blockages or leaks ensure normal operation of the production process.

more info...