Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM390

Used For

Industry Process Control, Control Pump, Air Dynamical Measure and Liquid Pressure Instrument, Medical Device, Vacuum Atmospheric and HVAC

Leave a MessageThe MDM390 differential pressure transducer is manufactured in an all-welded housing with G1/4 female threads. The static pressure transmitter is OEM type with max. static pressure 200bar. MDM390 is cable-connected and supplied with a constant-current power supply. It offers small size, precise performance, all-solid-state insulation, and high stability, reliability, and accuracy. The vacuum pressure transducer is also suitable for vacuum atmospheric, medical device and HVAC.

Features

• OEM differential pressure sensor

• Max. static pressure 200bar

Specifications

• Pressure range: 0~0.35bar…35bar

• Zero output: ≤2mVDC

• Output signal: ≥60mVDC

• +Overpressure: 2 times FS

• -Overpressure: 1 time FS or 10bar(min. value is valid)

• Static pressure: ≤200bar

• Static pressure effect: ≤0.05mV/1bar

Image:

The MDM390 differential pressure transducer is manufactured in an all-welded housing with G1/4 female threads. The static pressure transmitter is OEM type with max. static pressure 200bar. MDM390 is cable-connected and supplied with a constant-current power supply. It offers small size, precise performance, all-solid-state insulation, and high stability, reliability, and accuracy. The vacuum pressure transducer is also suitable for vacuum atmospheric, medical device and HVAC.

Features

• OEM differential pressure sensor

• Max. static pressure 200bar

Specifications

• Pressure range: 0~0.35bar…35bar

• Zero output: ≤2mVDC

• Output signal: ≥60mVDC

• +Overpressure: 2 times FS

• -Overpressure: 1 time FS or 10bar(min. value is valid)

• Static pressure: ≤200bar

• Static pressure effect: ≤0.05mV/1bar

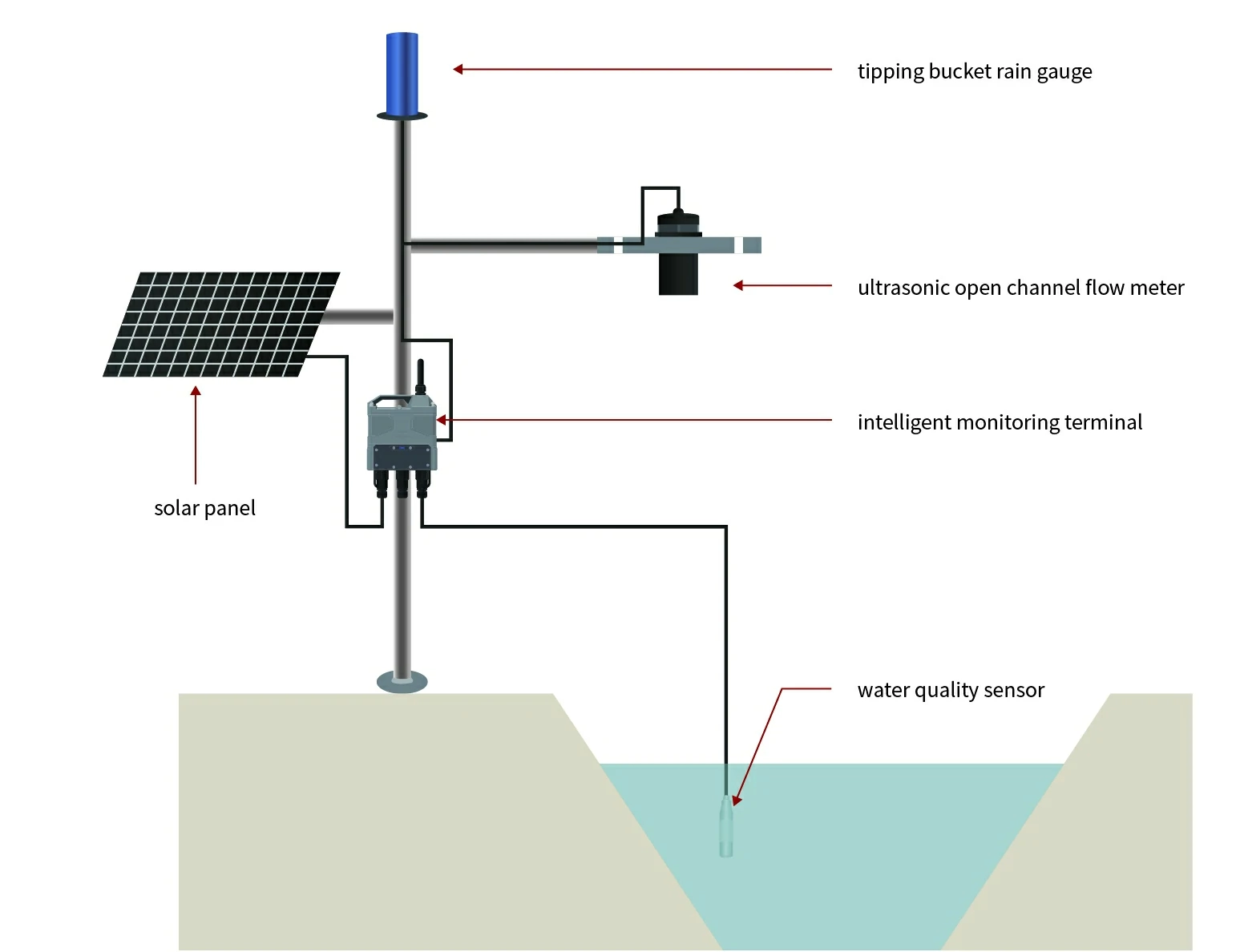

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...

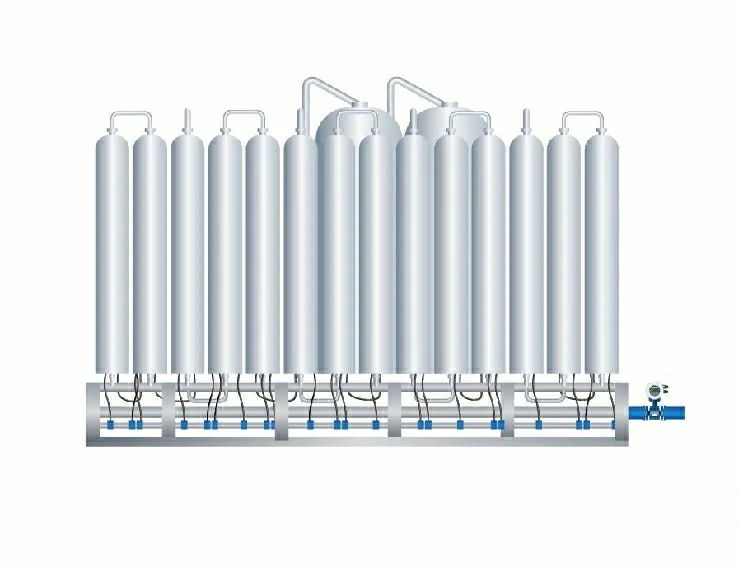

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...

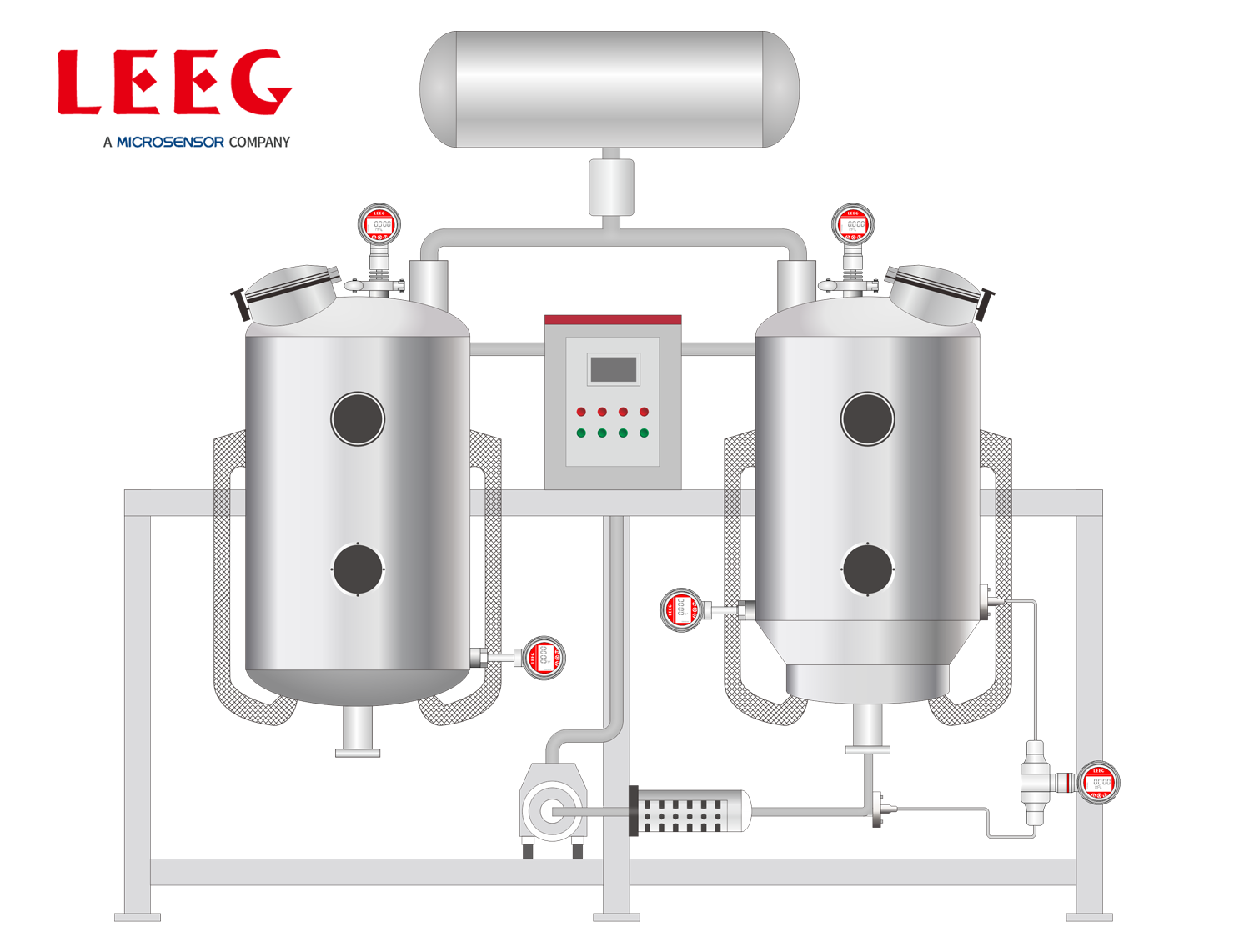

The production of different paste-like drugs uses a concentration process when processing raw materials. The evaporator features high temperature and vacuum. After the concentration process, it needs to be cleaned with efficient and strong chemical detergents. The pressure, temperature and level transmitters in the evaporator effectively ensure the normal and efficient operation of the concentration and washing process.

more info...

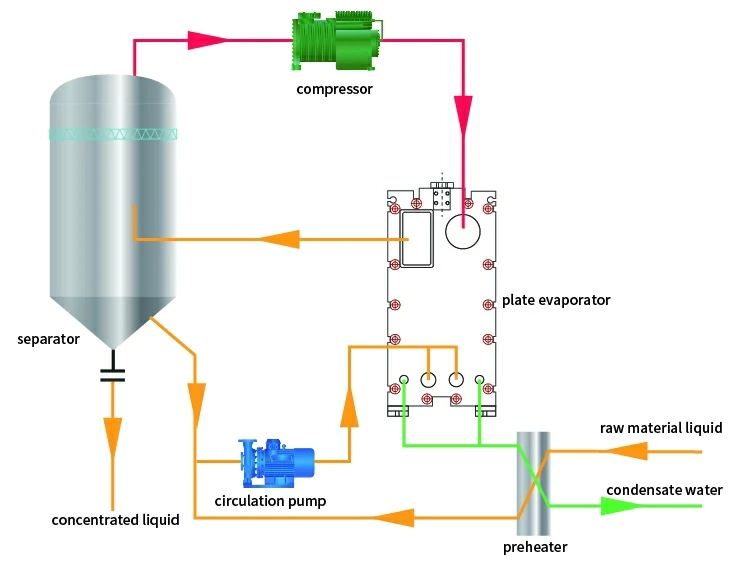

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...