Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM430

Used For

Petrochemical Industry, Power Plant, Mine, Urban Water Supply, Hydro Exploration

Leave a MessageThe MPM430 low range pressure transmitter is designed for low pressure measurements. The low pressure sensor offers two pressure port configurations to choose from, general and non-cavity, with a large contact area between the sensing diaphragm and the medium. The low pressure transducer adopts high-performance ceramic pressure sensor and fully sealed stainless steel structure. Compact size and reliable performance.

Features

• Pressure port has general, non-cavity two structures available. The contact surface between the pressure-sensing diaphragm and the medium is large

• Overpressure can reach dozens of times, which can resist strong pressure shocks

• Intrinsic safety type, Ex ia IIC T6 Ga

Specifications

• Pressure Type: gauge (with negative pressure measurement) absolute

• Long-term Stability: ±0.5%FS/year

• Thermal Drift:

≤±0.15%FS/10℃ (-20℃ ~ 80℃ )

≤±0.2%FS/10℃(-30℃ ~ -20℃ )

• Application Temperature:

-30℃ ~ 80℃ (plug connector type)

-20℃ ~ 70℃ (cable type, cable material: PE, PVC)

Material

• Wetted Parts

Isolated Diaphragm: 96% alumina ceramics

Pressure Port: SS 304

• Non-wetted Parts

Housing: SS 304/SS 316L

Cable: PE/PUR/PVC

Image:

The MPM430 low range pressure transmitter is designed for low pressure measurements. The low pressure sensor offers two pressure port configurations to choose from, general and non-cavity, with a large contact area between the sensing diaphragm and the medium. The low pressure transducer adopts high-performance ceramic pressure sensor and fully sealed stainless steel structure. Compact size and reliable performance.

Features

• Pressure port has general, non-cavity two structures available. The contact surface between the pressure-sensing diaphragm and the medium is large

• Overpressure can reach dozens of times, which can resist strong pressure shocks

• Intrinsic safety type, Ex ia IIC T6 Ga

Specifications

• Pressure Type: gauge (with negative pressure measurement) absolute

• Long-term Stability: ±0.5%FS/year

• Thermal Drift:

≤±0.15%FS/10℃ (-20℃ ~ 80℃ )

≤±0.2%FS/10℃(-30℃ ~ -20℃ )

• Application Temperature:

-30℃ ~ 80℃ (plug connector type)

-20℃ ~ 70℃ (cable type, cable material: PE, PVC)

Material

• Wetted Parts

Isolated Diaphragm: 96% alumina ceramics

Pressure Port: SS 304

• Non-wetted Parts

Housing: SS 304/SS 316L

Cable: PE/PUR/PVC

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

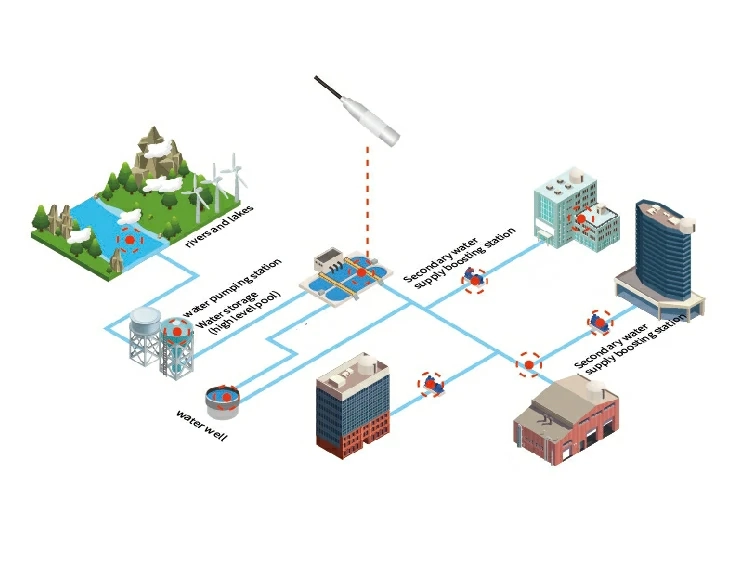

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

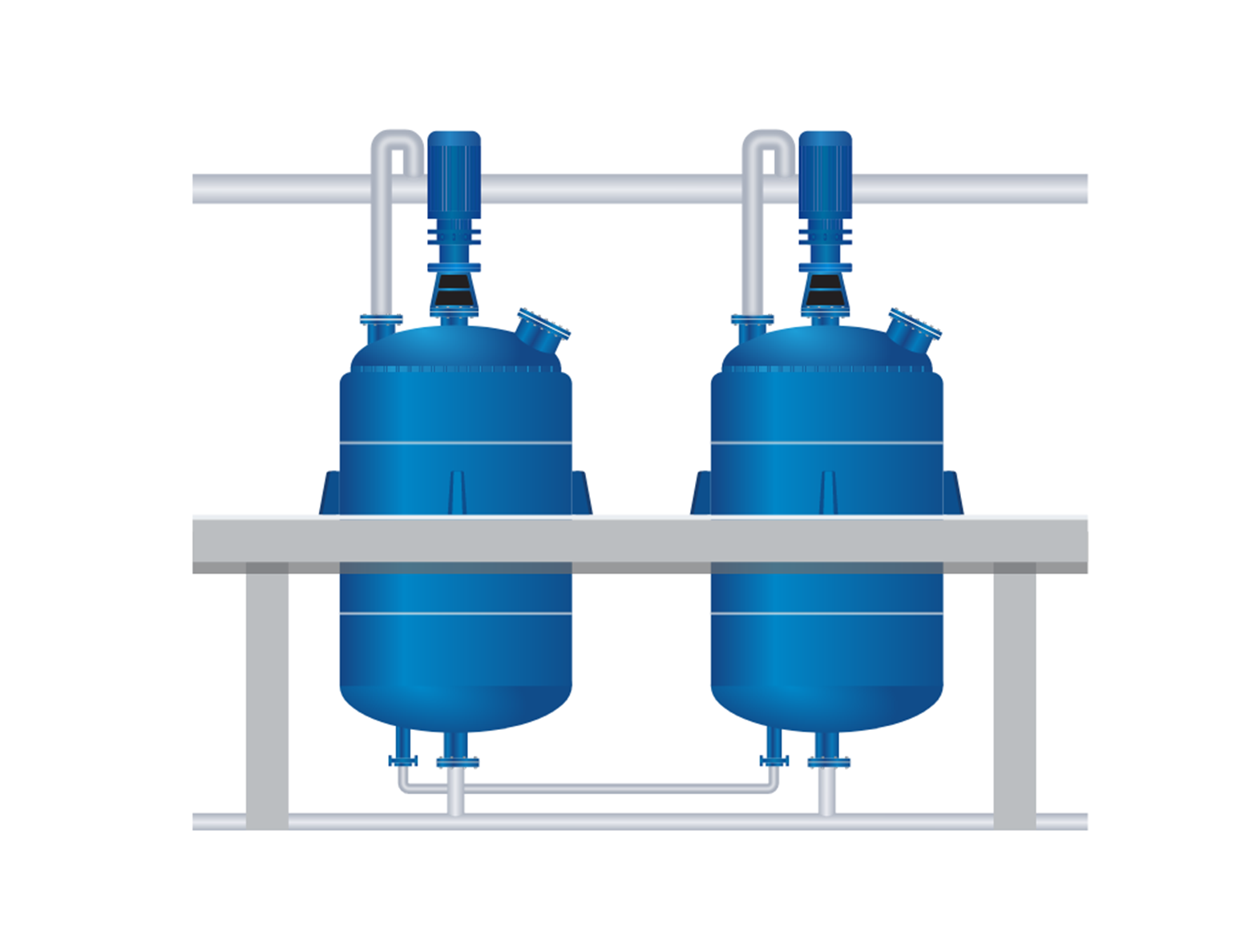

During machine downtime or product changes, the press rolls are cleaned and coated with a specialist solution to protect against adhesions and deposits, hence avoiding paper difficulties. The 50°C coating mixture is pushed through the machine. To maintain automated functioning, the tank's level and filter status must be continuously monitored.

more info...

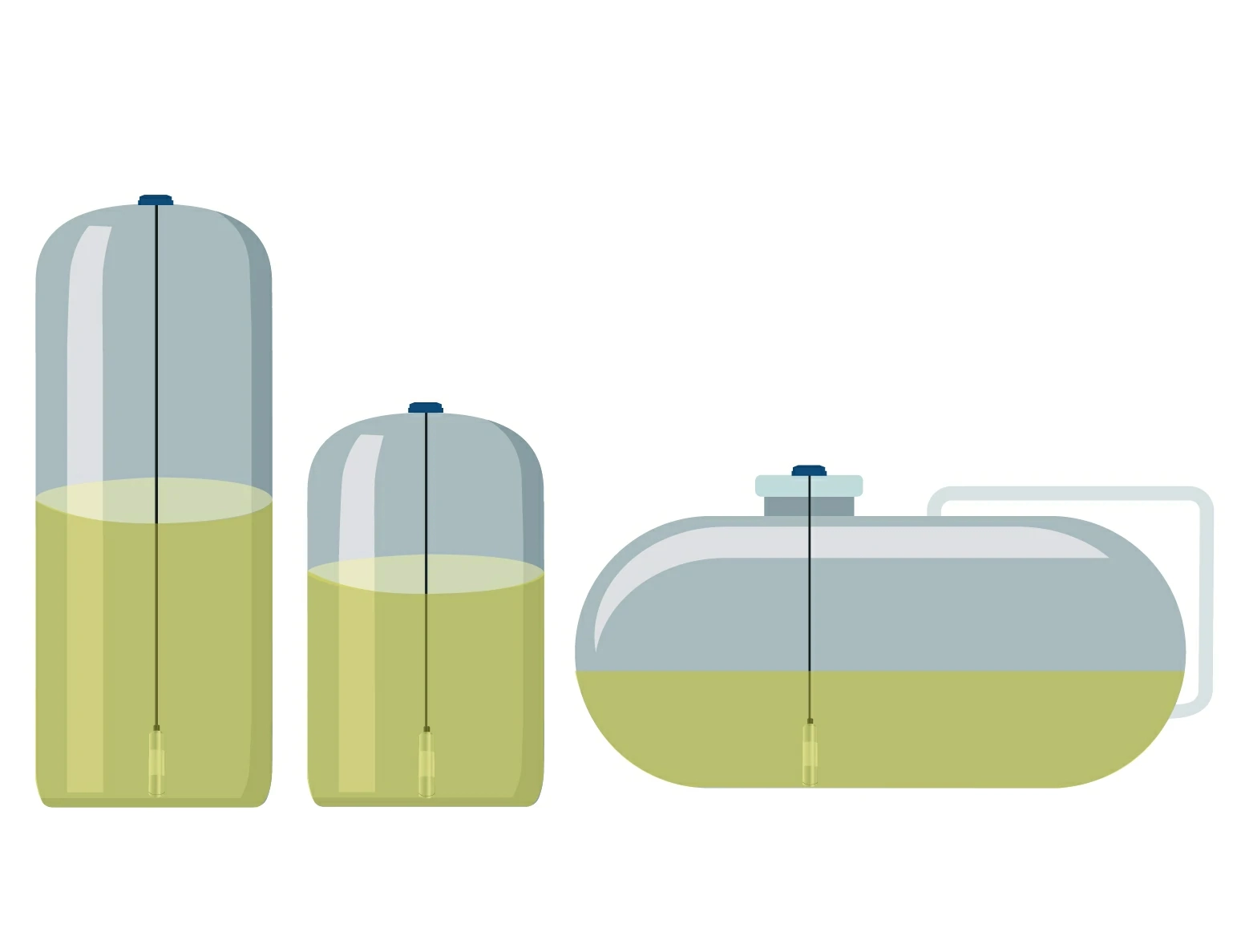

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

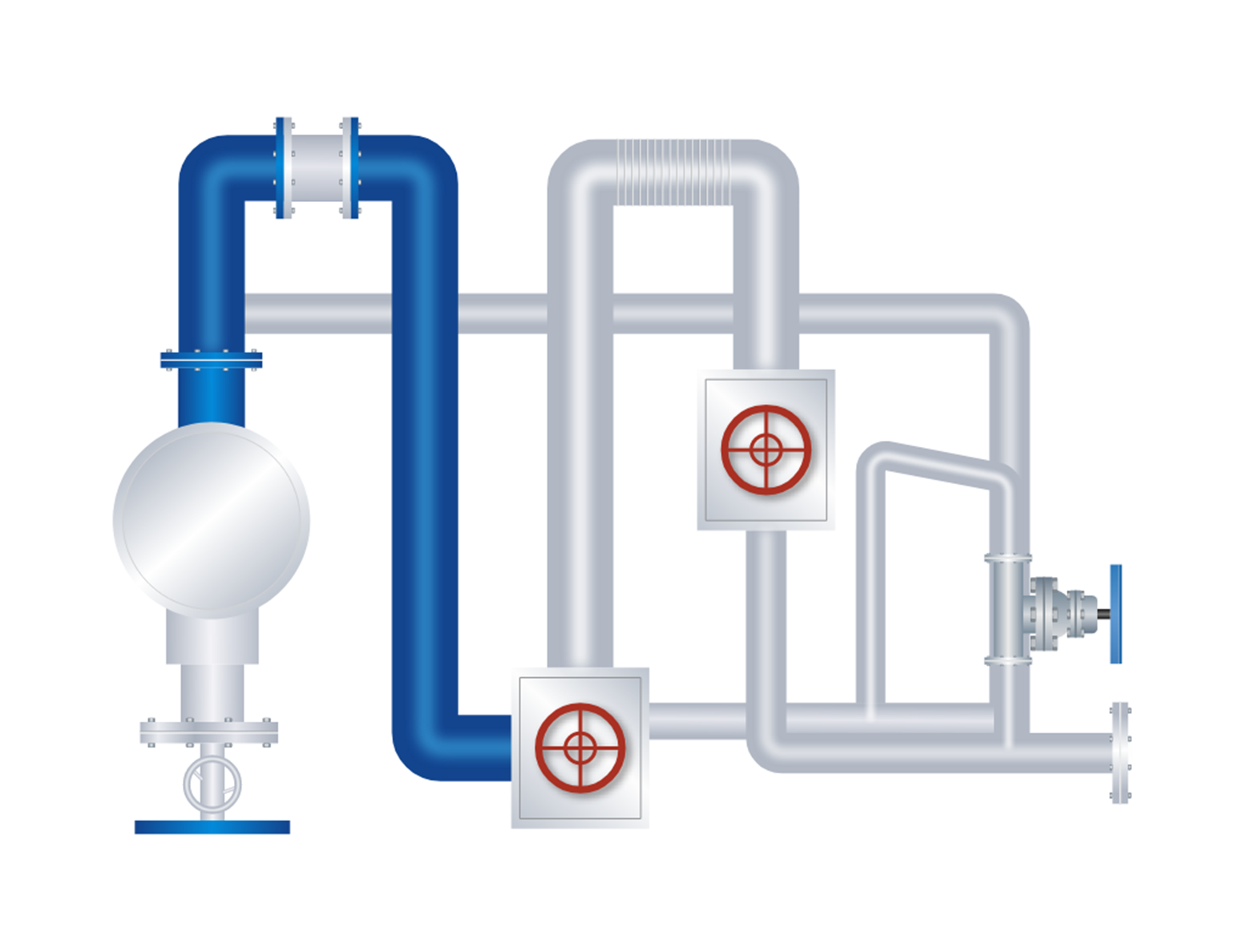

The paper machine's drying section employs steam-heated cylinders, with steam generated by a separate boiler and transported by pipelines. To ensure optimal steam supply, a differential pressure transmitter with an orifice plate is used to measure flow, allowing for accurate planning.

more info...