Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

MPM4891B

Used For

Production of Pressure Transmitter and Transducer, Industrial Process Control, Aviation and Navigation Inspection

Leave a MessageMPM4891B Analog Output Pressure Transmitter is special for instruments and apparatus manufacturers. MPM4891B is an OEM package. It is the best choice for the application and development of various pressure transmitters. MPM4891B consists of a piezoresistive pressure sensing element and a dedicated processing circuit. The analog pressure transmitter outputs standard 4-20mADC ranging from 0.1bar to 400bar. This product can achieve zeroing in 5 seconds without pressure. Manual pressure calibration mode is easy to operate.

Specification

• Range: 0bar~0.1bar…400bar

• Overpressure: 1.5FS

• Operation Temp.: -25~75°C

• O-ring: Viton

• Diaphragm: SS316L

• Leading Wire: silicone rubber

Image:

MPM4891B Analog Output Pressure Transmitter is special for instruments and apparatus manufacturers. MPM4891B is an OEM package. It is the best choice for the application and development of various pressure transmitters. MPM4891B consists of a piezoresistive pressure sensing element and a dedicated processing circuit. The analog pressure transmitter outputs standard 4-20mADC ranging from 0.1bar to 400bar. This product can achieve zeroing in 5 seconds without pressure. Manual pressure calibration mode is easy to operate.

Specification

• Range: 0bar~0.1bar…400bar

• Overpressure: 1.5FS

• Operation Temp.: -25~75°C

• O-ring: Viton

• Diaphragm: SS316L

• Leading Wire: silicone rubber

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...

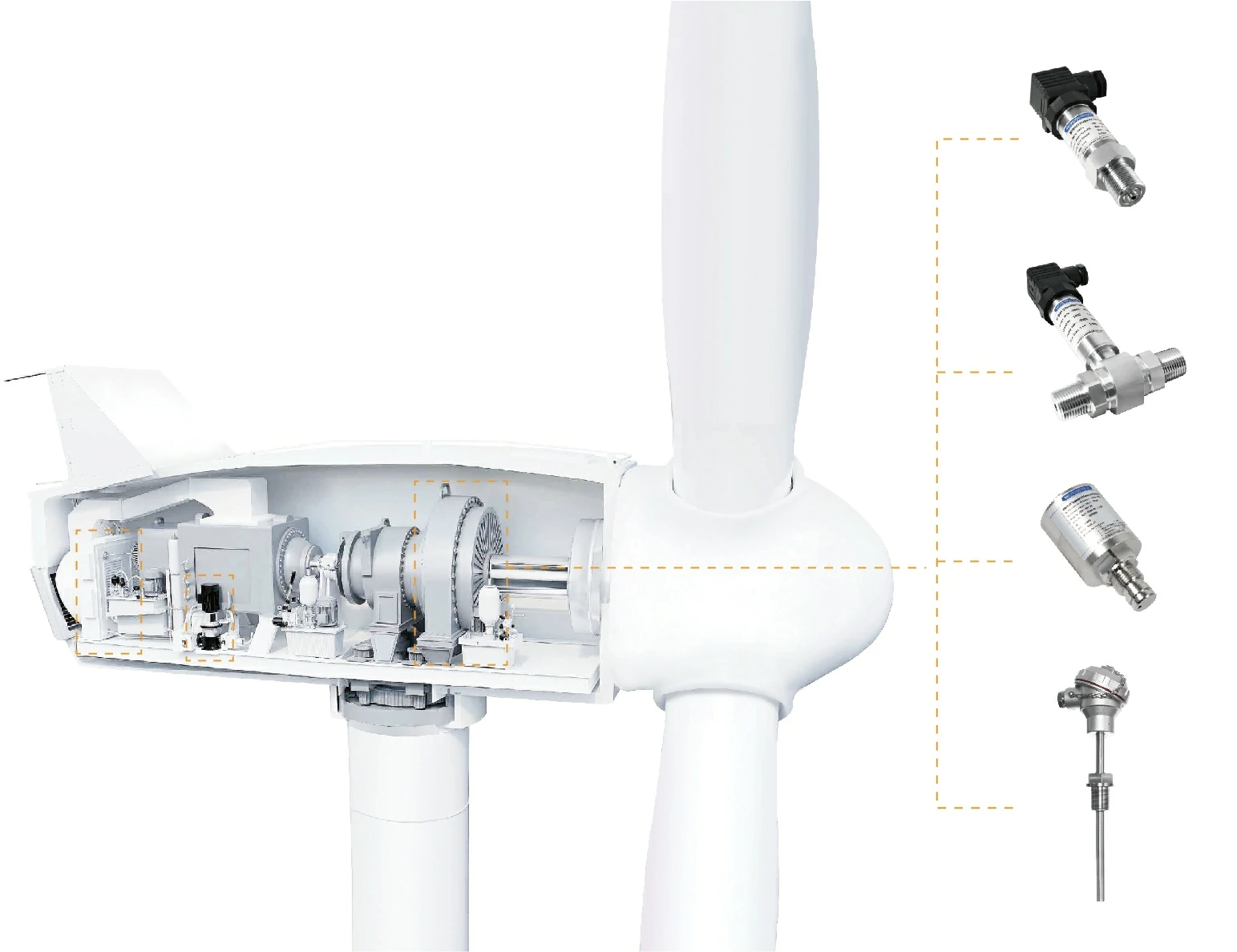

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...

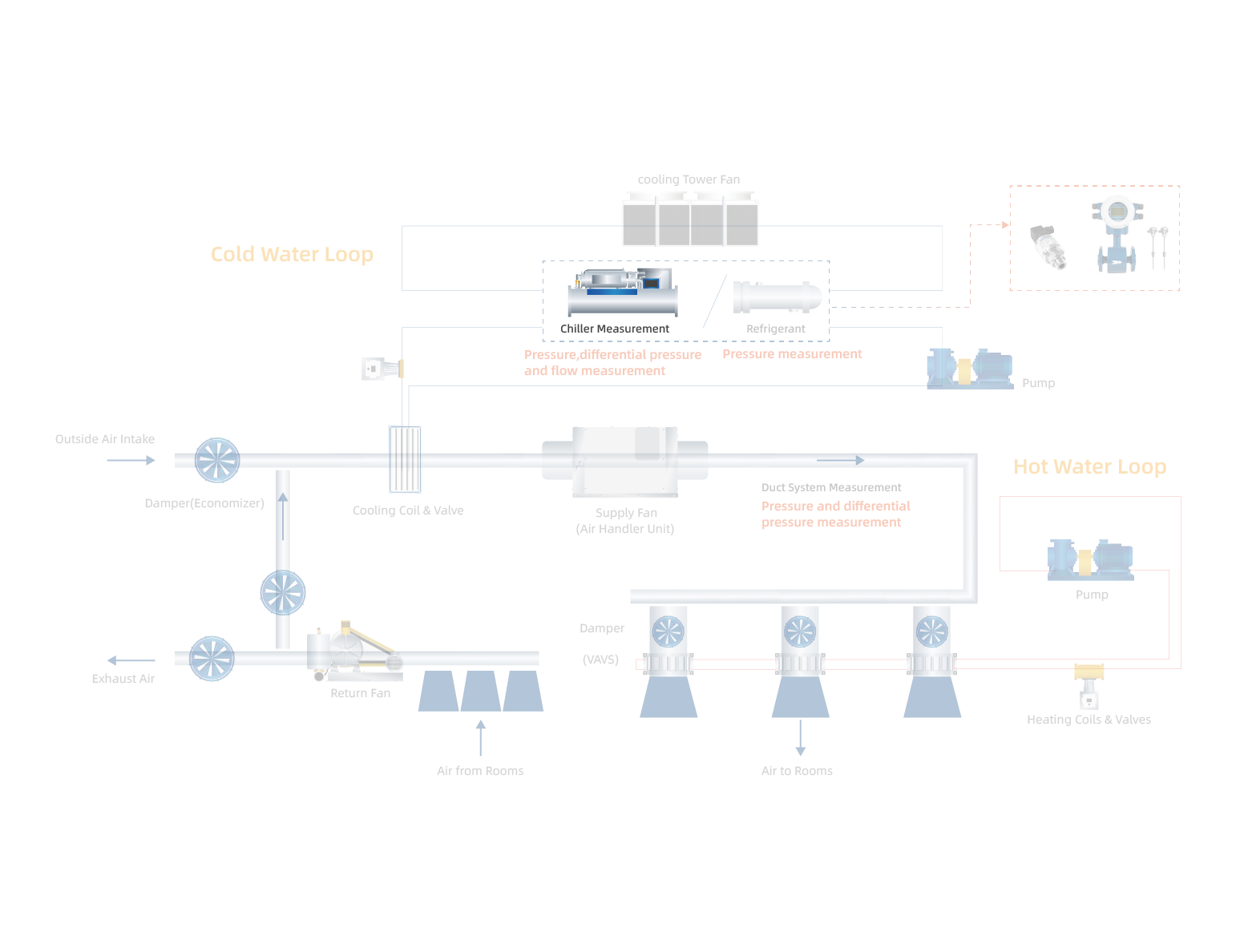

In the HVAC chiller systems, measuring heat and pressure is vital for optimal performance. Pressure transmitters ensure the refrigerant operates within safe limits, while flow meters and temperature sensors calculate heat exchange efficiency. Accurate measurements enhance system reliability, and efficiency, and prevent potential failures.

more info...

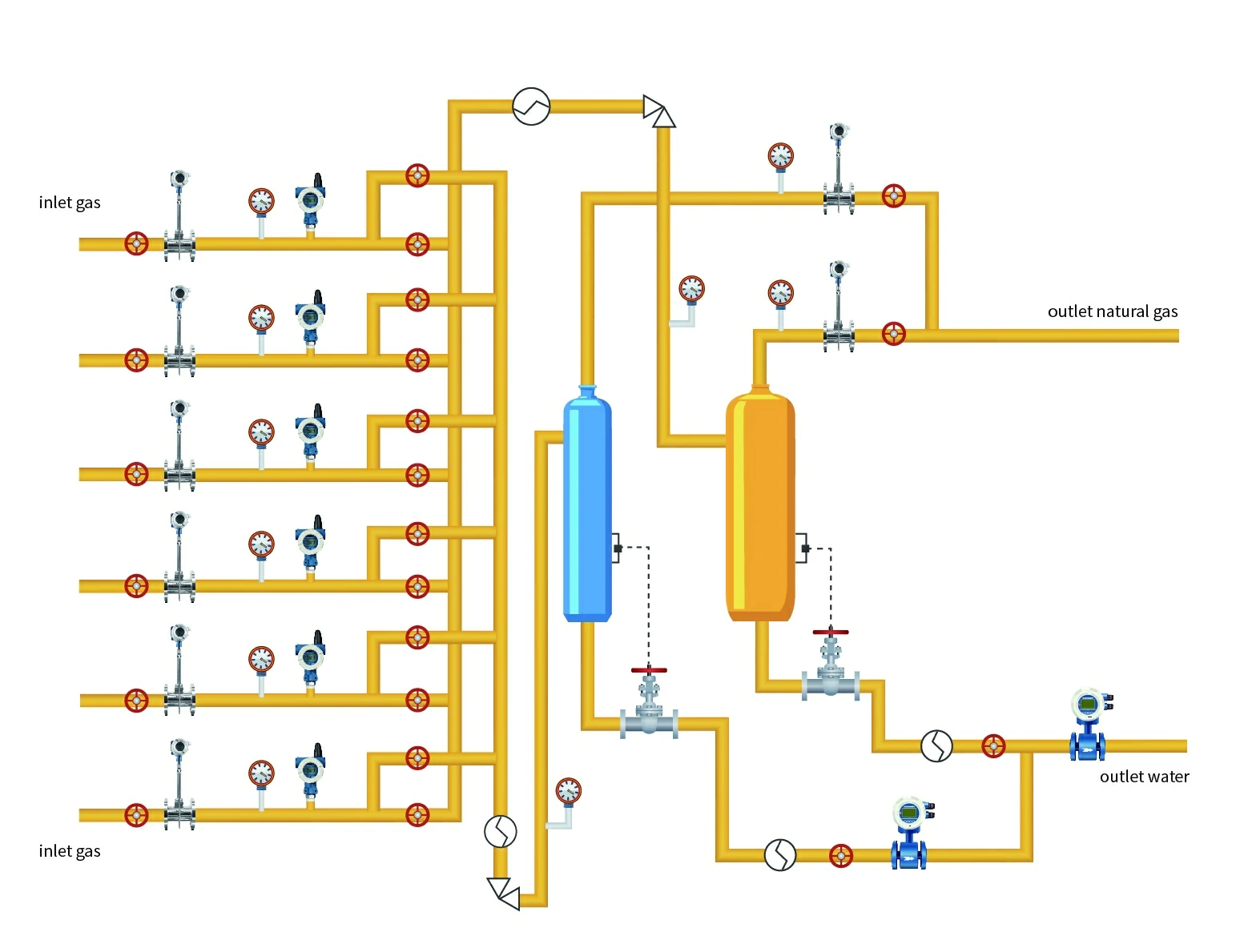

Gas gathering stations gather and process natural gas from multiple wells. Instruments in the pipeline monitor real-time data changes, such as gas or liquid flow. It helps control the water injection for the purpose of measuring and transporting oil and gas.

more info...