Temperature Transmitting Controller

Temperature Range: -30~150℃ / -22~302℉

Accuracy: ≤±1℃ (FS≤100℃ ); ≤±2℃ (FS>100℃ )

Intrinsic safe version available

MPM4809TD

Used For

The diesel level transmitter is atex approved, suitable for 2m diesel oil level measurement and control in chemical industry, medicine, metallurgy, power plant, mine, city water drainage and hydrology.

Leave a Message

MPM4809TD submersible level transmitter is widely used in telecom tower station for fuel, diesel level measurement. With complete media compatibility and thunder proof protection device, care free solution in remote working environment.

Image:

MPM4809TD submersible level transmitter is widely used in telecom tower station for fuel, diesel level measurement. With complete media compatibility and thunder proof protection device, care free solution in remote working environment.

Temperature Range: -30~150℃ / -22~302℉

Accuracy: ≤±1℃ (FS≤100℃ ); ≤±2℃ (FS>100℃ )

Intrinsic safe version available

Volume flux measurement

RS485 communication protocol

RS232 communication protocol

Accuracy:±0.2% URL

Range: 0.4bar~10bar

Output Signal: 4mA~20mA DC+HART

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±1.0%FS

Medium Temperature: -200℃~ 500℃

Output: 4mA ~ 20mADC, RS485, HART

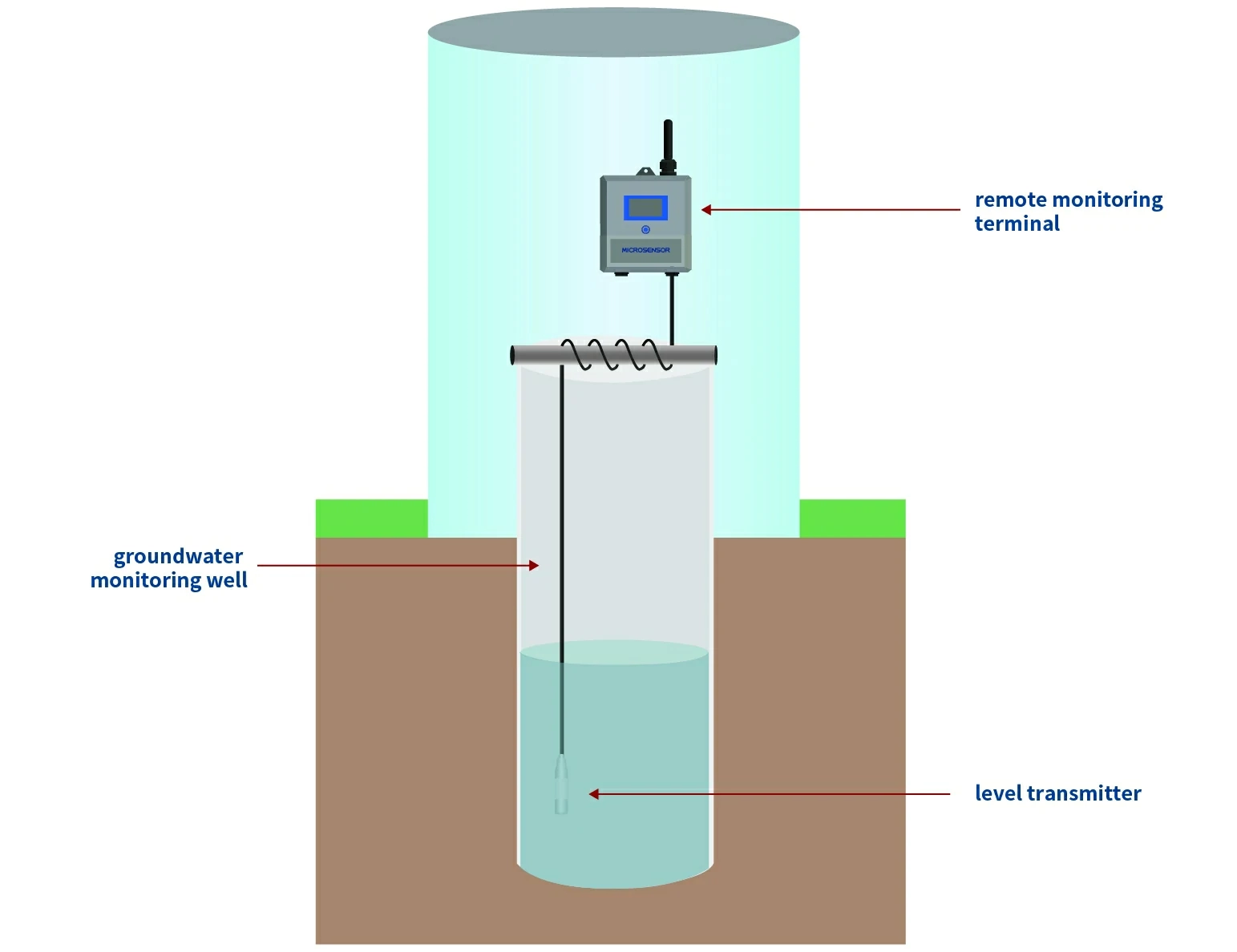

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

The roots flowmeter is the critical equipment in the system of urban gas gate station. As the basis of gas billing, roots flowmeter can accurately calculate the flow of natural gas. It is equipped with pressure transmitter with high accuracy, so as to guarantee the flow accuracy.

more info...

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

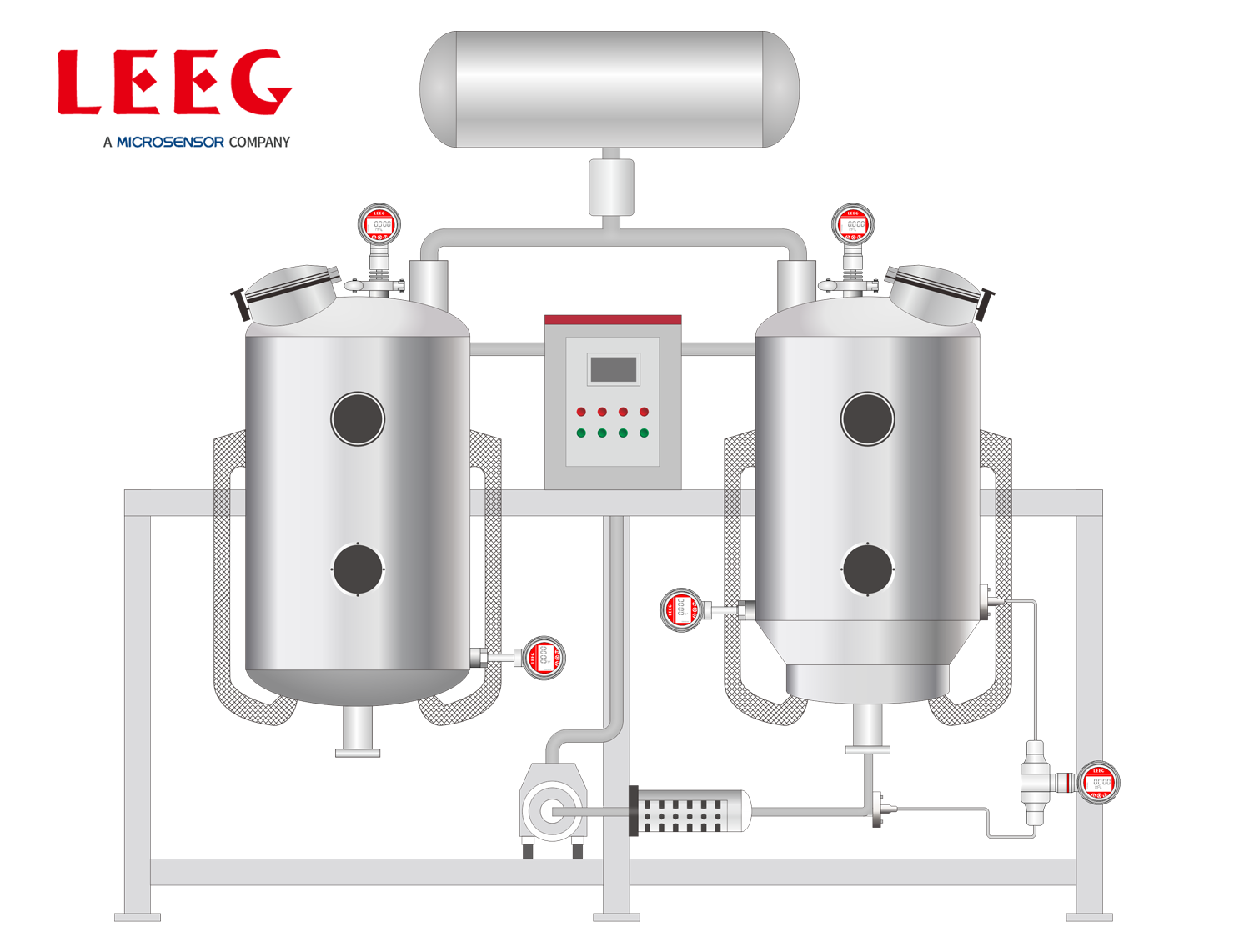

The production of different paste-like drugs uses a concentration process when processing raw materials. The evaporator features high temperature and vacuum. After the concentration process, it needs to be cleaned with efficient and strong chemical detergents. The pressure, temperature and level transmitters in the evaporator effectively ensure the normal and efficient operation of the concentration and washing process.

more info...