Pressure Transmitter

Range:10Bar~50Bar

Compact Size & Shock Resistance

Accuracy:±1%FS

MTM4881

Used For

Liquid Medium Temperature Measurement, Detection of Oil Temperature of Hydraulic and Lubrication Transmission System

Leave a MessageMTM4881 is a Temperature Transmitting Controller for measuring, displaying, transmitting, and controlling industrial processes. The switch support up to 5 relay and 1 analog output. 4 installation ways includes rail mounting, cover mounting, back mounting and joint mounting.

The product can achieve precise measurement and provide quick response and control of multiple relays under compensating and adjusting the sensor. The meter supports peak record and action delay, providing 4 digit LED indicator, easy to read. Multiple buttons design makes the easier operation and more convenient.

Features

• Real-time temperature display in unit: ℃ or ℉

• Button programming, easy operation

• Record the Max. in operation (button for clearing up)

• Support rail, cover and back mounting

• Switchable analog output

• Intrinsically safe, Exia mark is Ex ib IIA T6 Gb

• MODBUS

Specifications

Power Supply:

• Non Intrinsically Safe: (220±44)V AC / 22V~32V DC

• Intrinsically Safe: 22V~28V DC (Supplied by Safety Barrier)

• Range: 0kPa~10kPa... 60MPa

• Overpressure: 1.5 FS

• Accuracy: ≤±0.25%FS; ≤±0.5%FS

• Repeatability: ≤±0.2%FS

Image:

MTM4881 is a Temperature Transmitting Controller for measuring, displaying, transmitting, and controlling industrial processes. The switch support up to 5 relay and 1 analog output. 4 installation ways includes rail mounting, cover mounting, back mounting and joint mounting.

The product can achieve precise measurement and provide quick response and control of multiple relays under compensating and adjusting the sensor. The meter supports peak record and action delay, providing 4 digit LED indicator, easy to read. Multiple buttons design makes the easier operation and more convenient.

Features

• Real-time temperature display in unit: ℃ or ℉

• Button programming, easy operation

• Record the Max. in operation (button for clearing up)

• Support rail, cover and back mounting

• Switchable analog output

• Intrinsically safe, Exia mark is Ex ib IIA T6 Gb

• MODBUS

Specifications

Power Supply:

• Non Intrinsically Safe: (220±44)V AC / 22V~32V DC

• Intrinsically Safe: 22V~28V DC (Supplied by Safety Barrier)

• Range: 0kPa~10kPa... 60MPa

• Overpressure: 1.5 FS

• Accuracy: ≤±0.25%FS; ≤±0.5%FS

• Repeatability: ≤±0.2%FS

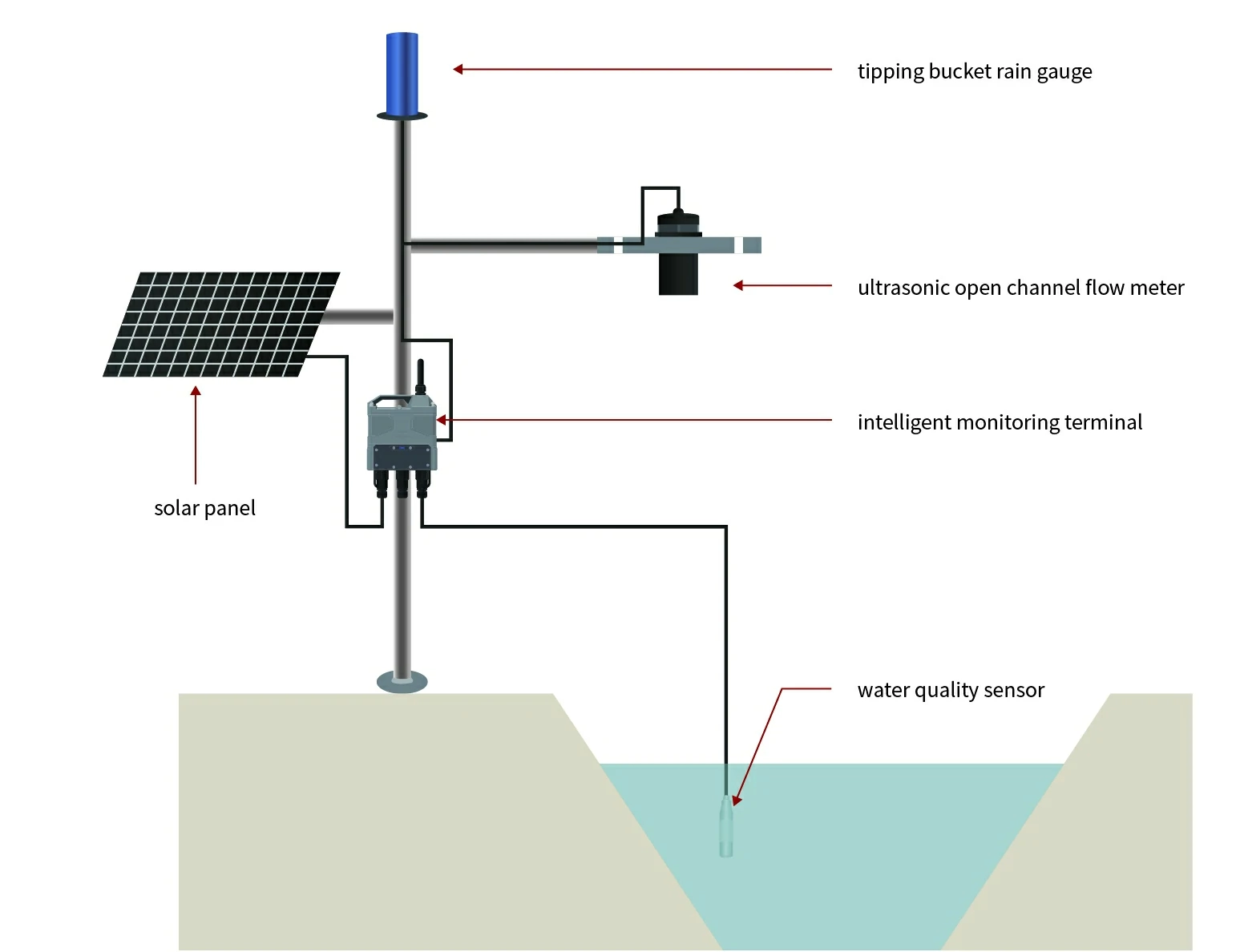

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...

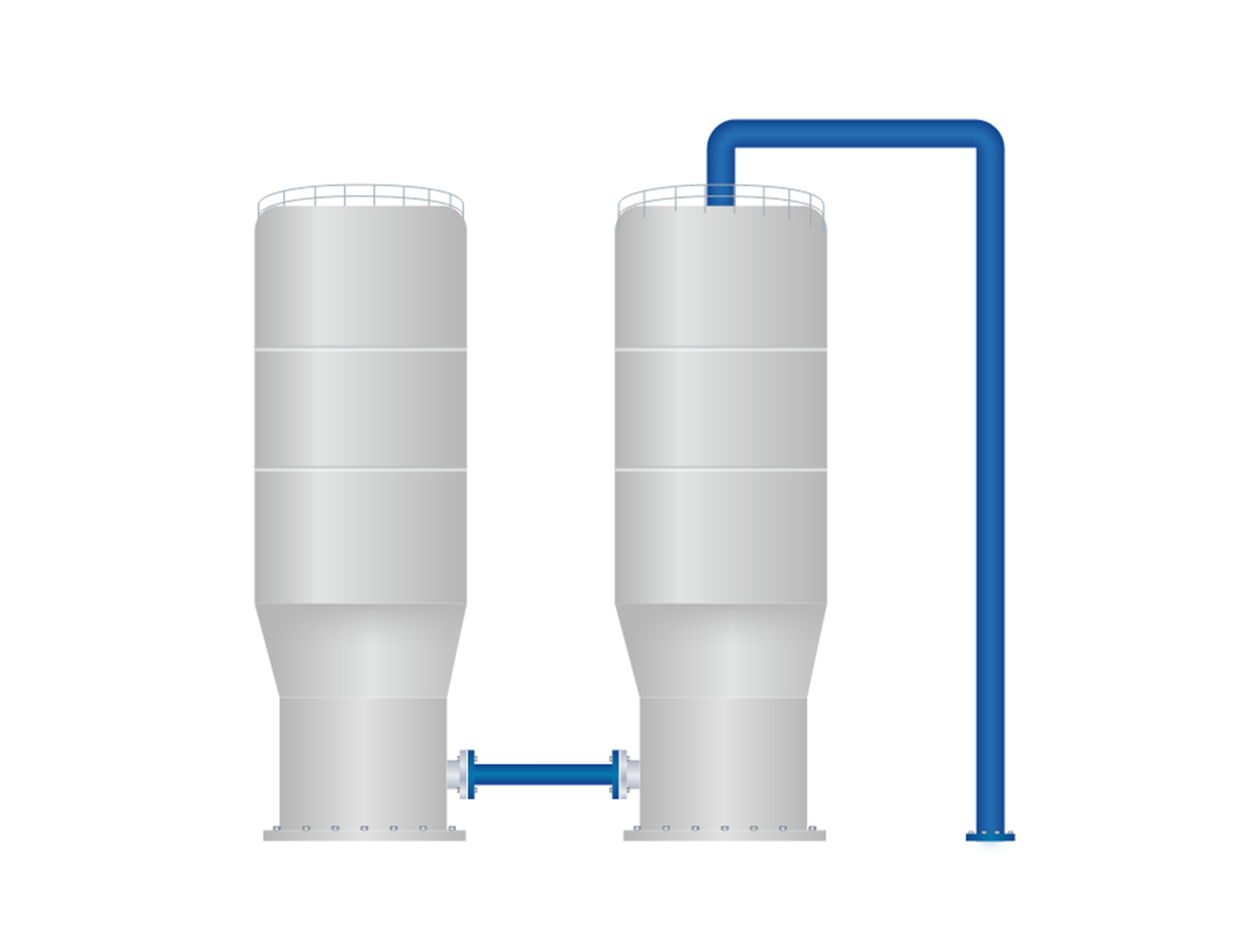

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

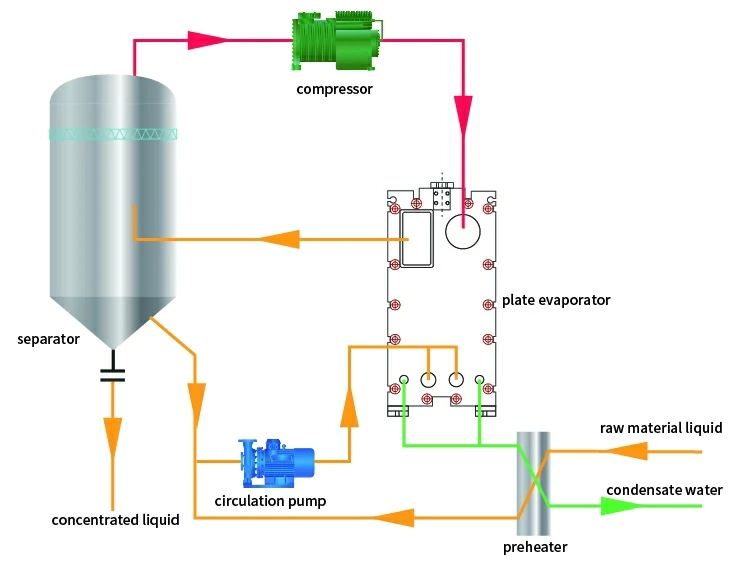

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

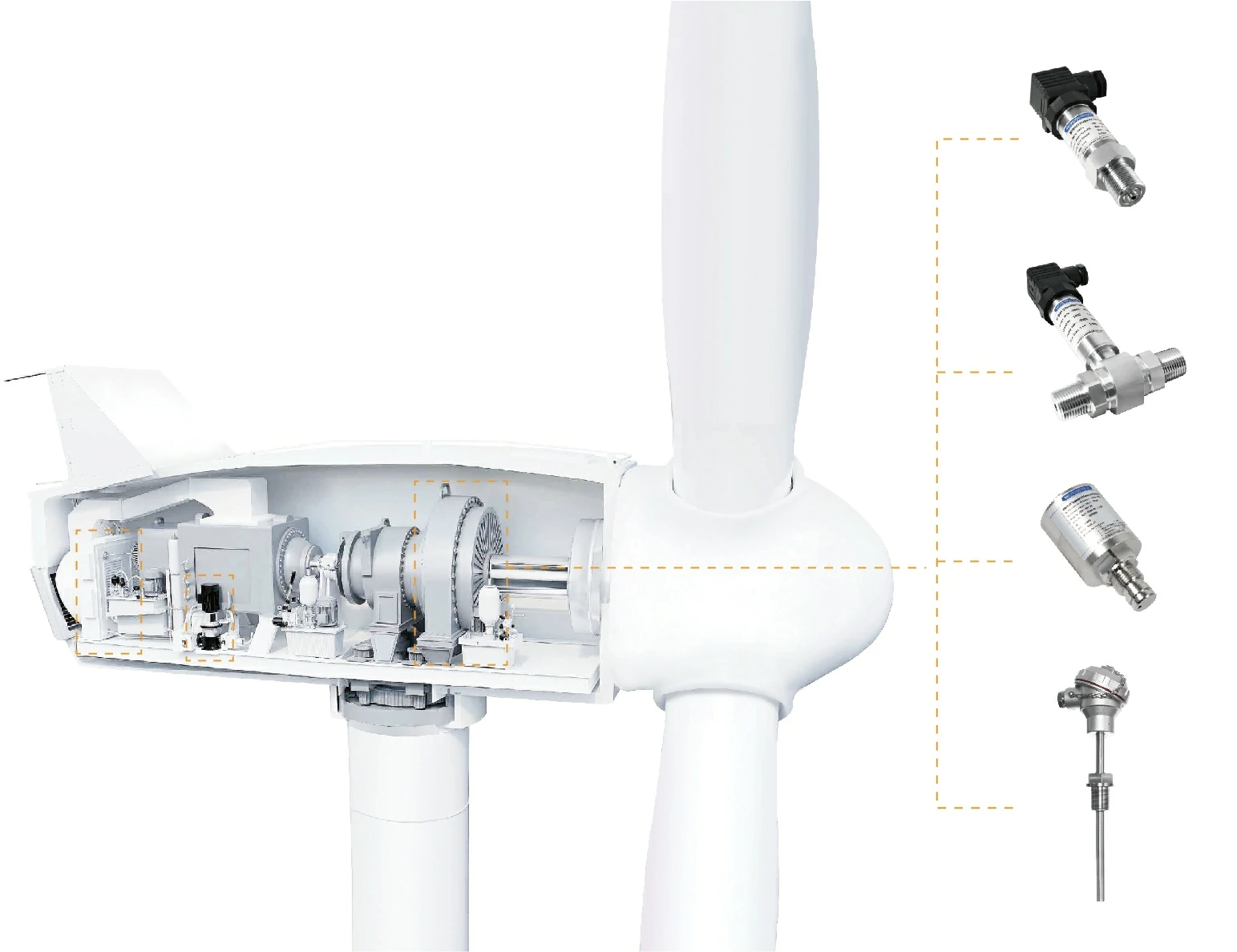

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...