Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM436W

Used For

Chemical Engineering, Urban Water Supply and Drainage, Hydrological Exploration

Leave a MessageThe measurable range of MPM436W level transmitter for low level is between 0.5m and 2m. Compared with other lever meters, MPM436W is more suitable for measuring low liquid level measurement scenarios in urban water supply and drainage systems or chemical industry. Both the sensor and the amplifying circuit are in a liquid-immersed fully sealed stainless steel structure. The high-performance hydrostatic pressure sensor can accurately measure the hydrostatic pressure proportional to the depth of the liquid level. The removable top stainless steel cap of the MicroSensor MPM436W facilitates regular cleaning and prevents accidental damage to the diaphragm.

Feature

• Low-range liquid level measurement and control

• IP68 protection level of submersible part

• Accuracy of ±0.5%FS min

• Resist strong pressure shock

Image:

The measurable range of MPM436W level transmitter for low level is between 0.5m and 2m. Compared with other lever meters, MPM436W is more suitable for measuring low liquid level measurement scenarios in urban water supply and drainage systems or chemical industry. Both the sensor and the amplifying circuit are in a liquid-immersed fully sealed stainless steel structure. The high-performance hydrostatic pressure sensor can accurately measure the hydrostatic pressure proportional to the depth of the liquid level. The removable top stainless steel cap of the MicroSensor MPM436W facilitates regular cleaning and prevents accidental damage to the diaphragm.

Feature

• Low-range liquid level measurement and control

• IP68 protection level of submersible part

• Accuracy of ±0.5%FS min

• Resist strong pressure shock

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

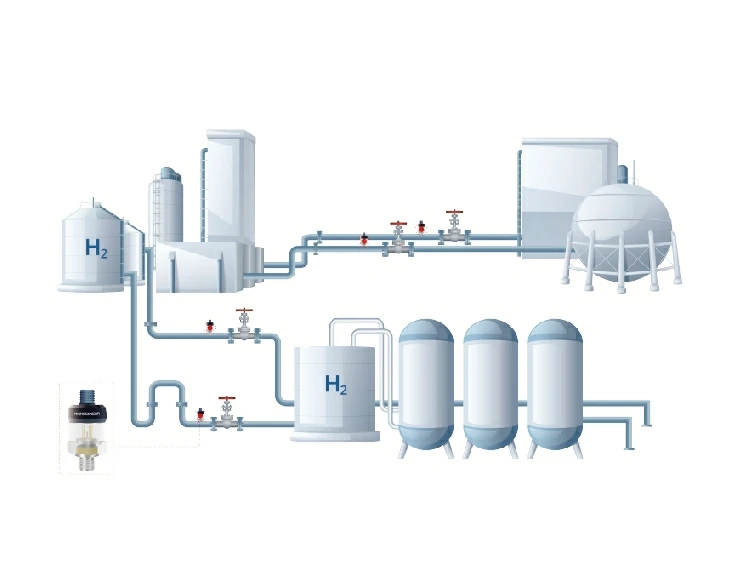

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...

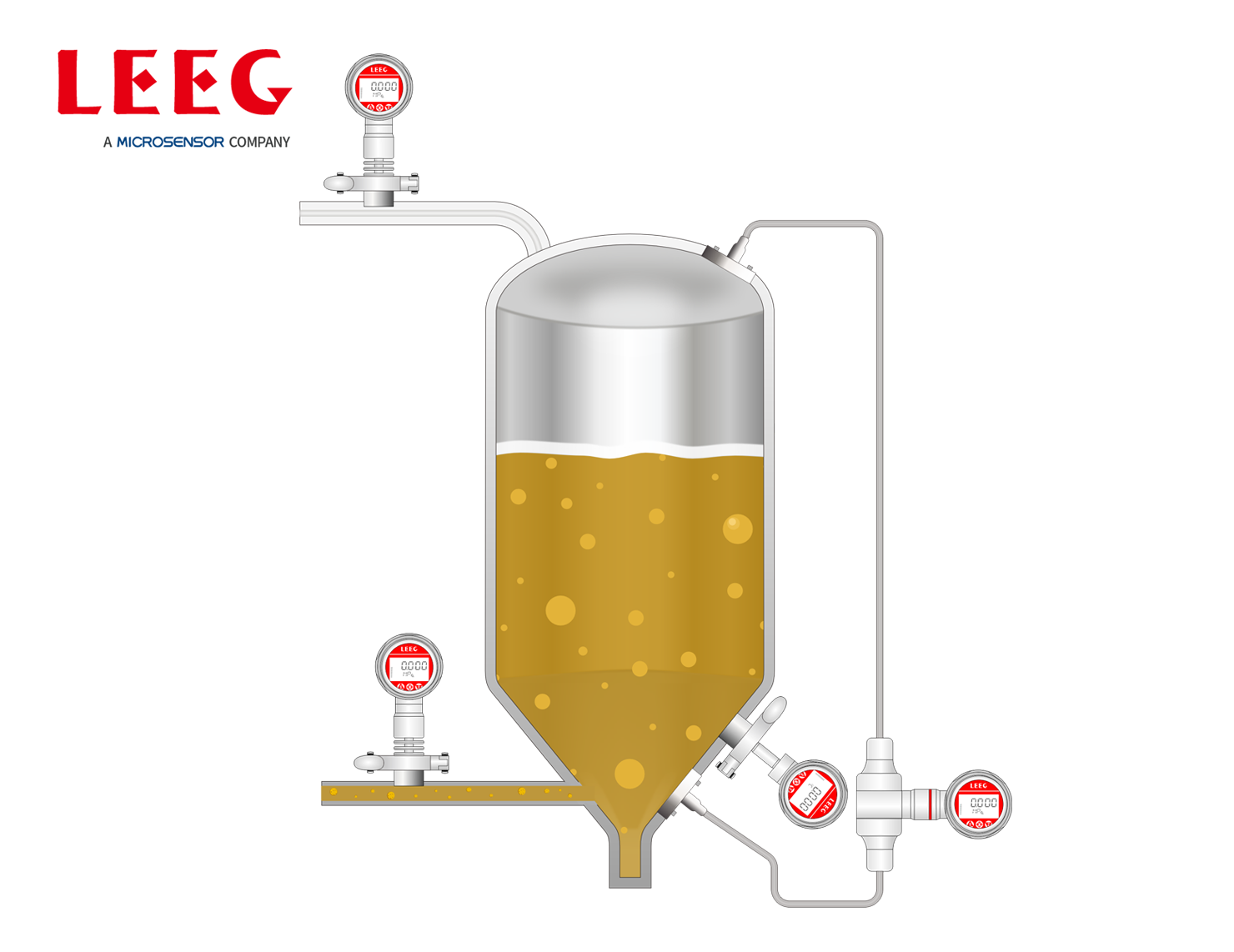

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

more info...

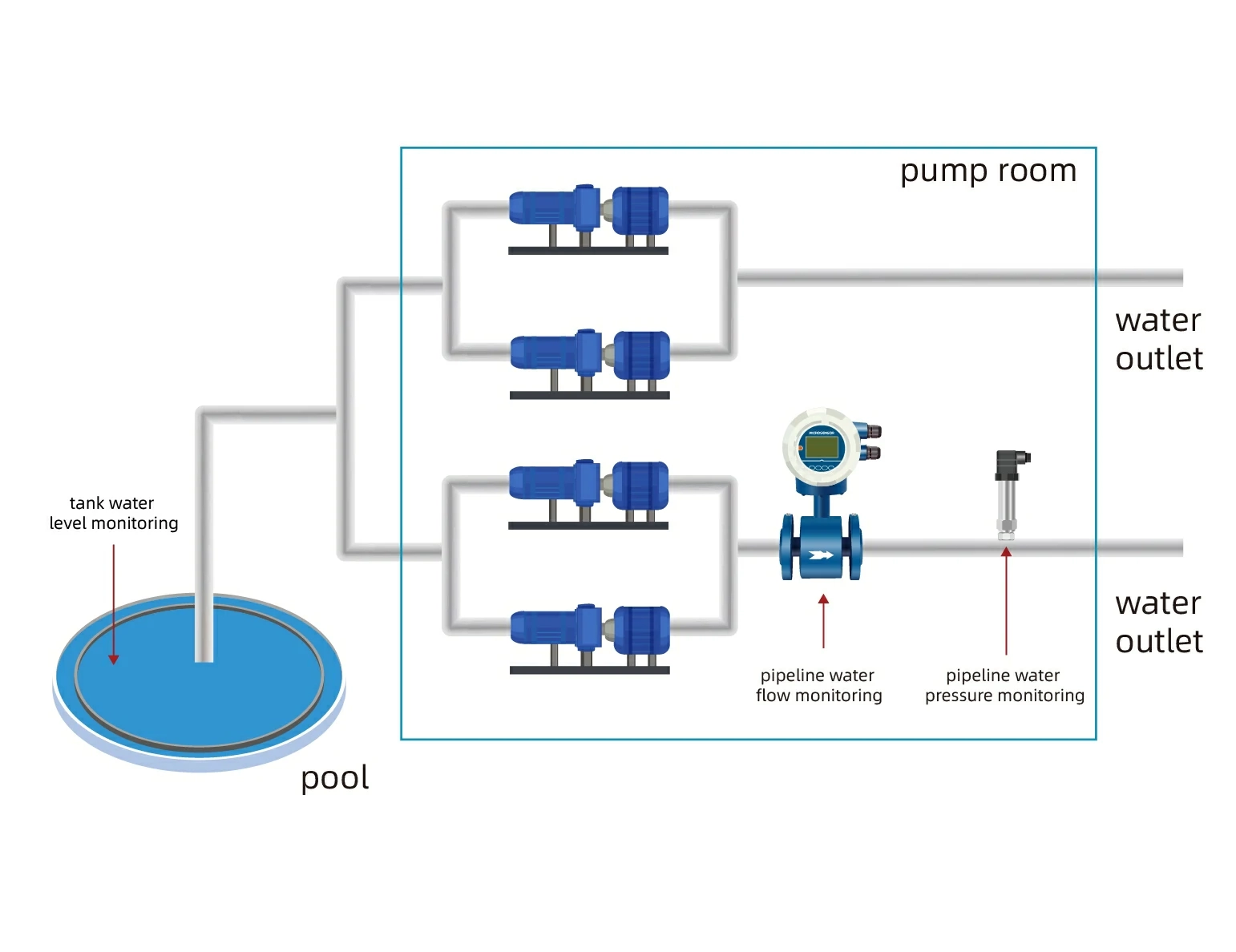

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

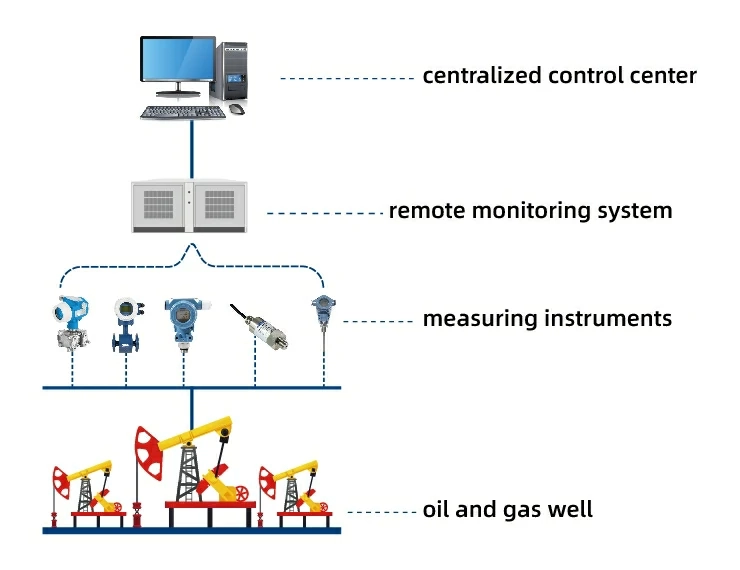

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...