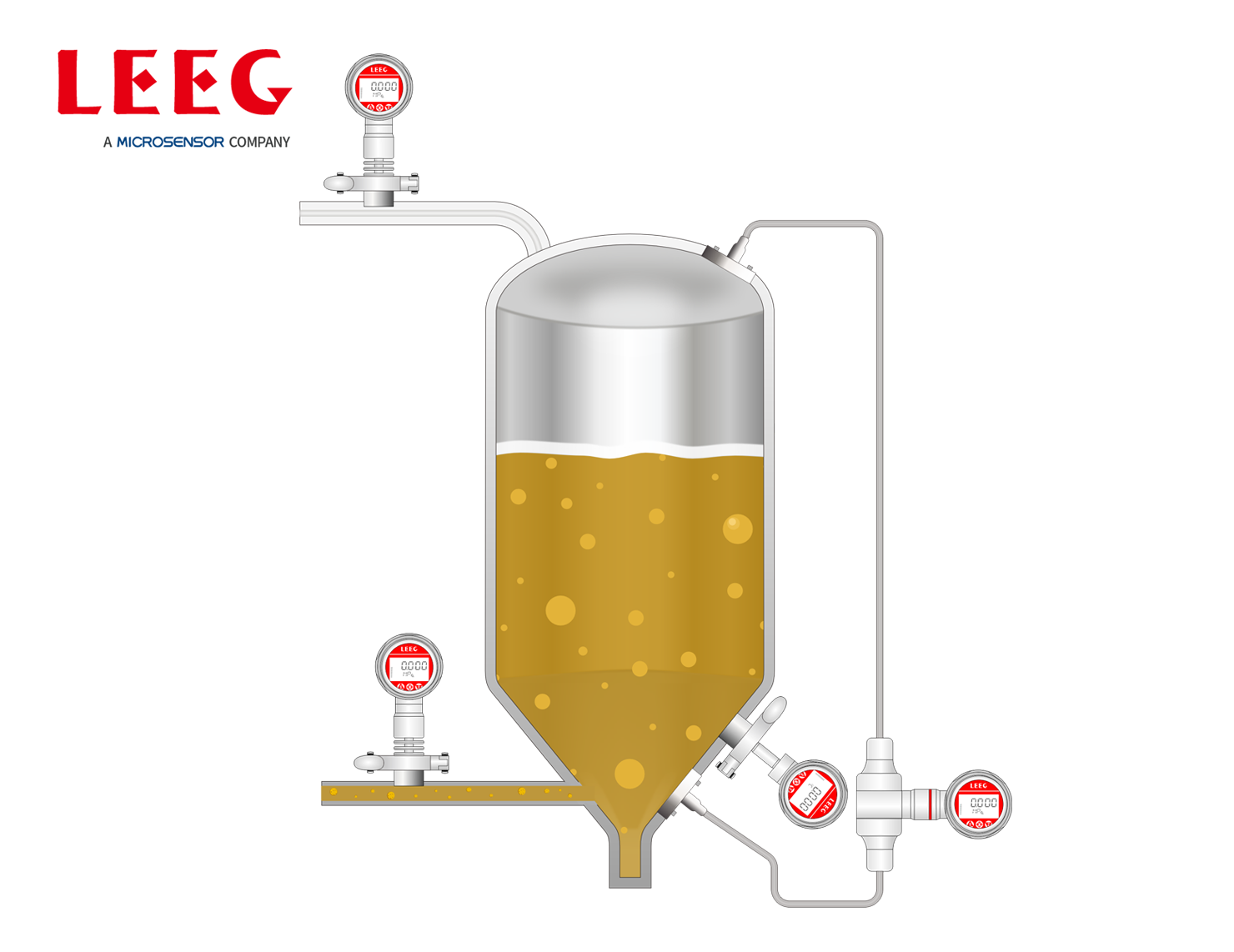

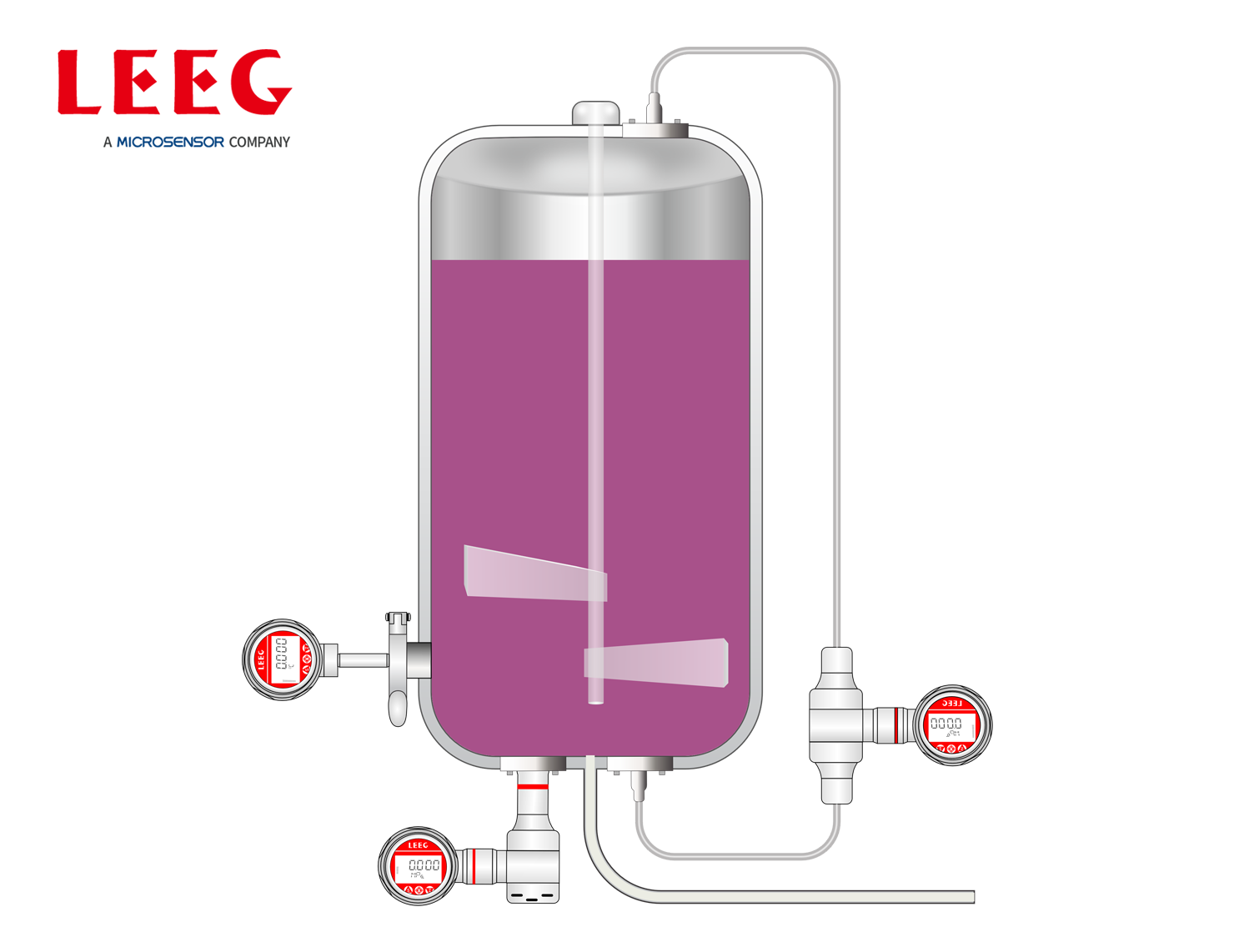

Application Challenges:

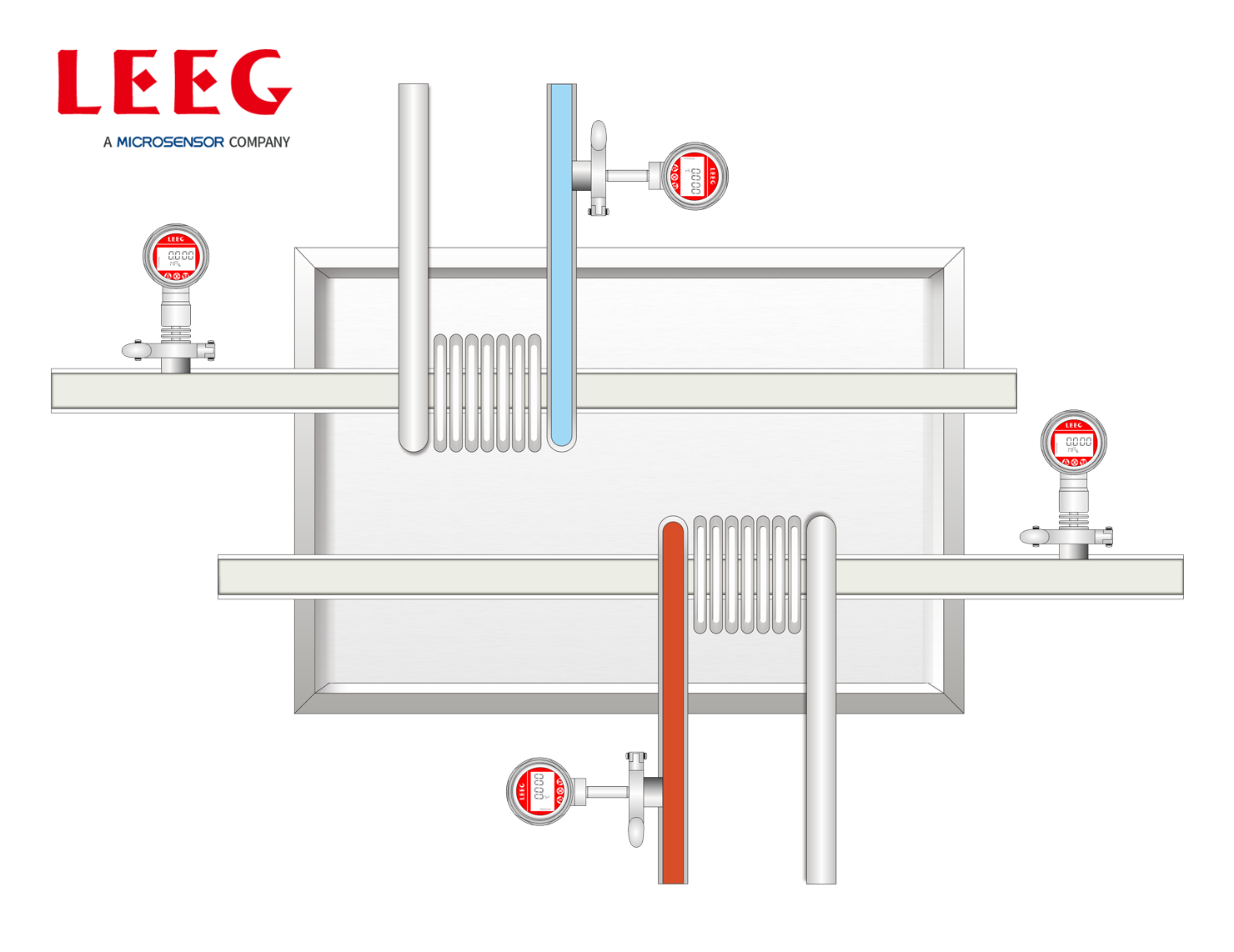

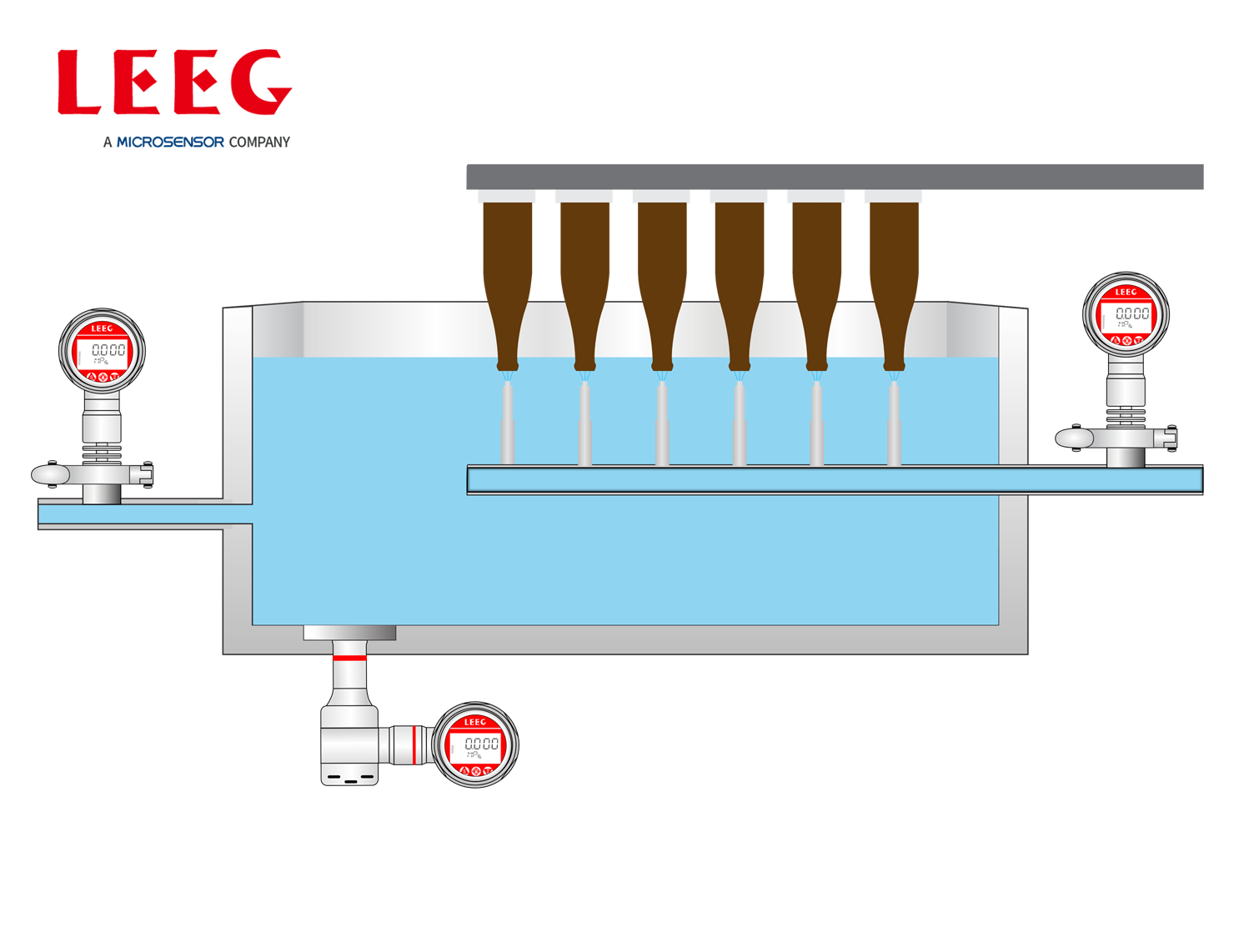

1. Since beer fermentation is regularly cleaned by CIP online, the transmitter must have high accuracy and stability to cope with the impact of frequent high temperatures and corrosive cleaning fluids.

2. During the fermentation process, temperature and pressure need to be precisely controlled. The transmitter must maintain high stability in the low pressure and lower temperature range.

3. During fermentation, the action of yeast will form foam. These foams may interfere with the level or pressure measurement of the transmitter, resulting in inaccurate measurement data.

4. The fermentation process usually lasts for days or weeks, requiring the transmitter to have long-term stability without frequent calibration or maintenance.

Solution Advantages:

1. Hygienic transmitters adopt an integral 316L stainless steel sink to ensure the impact of high-temperature steam in the CIP.

2. Temperature compensation technology ensures the stability of measuring data under varying temperatures.

3. The optimized installation position can avoid the interference of foam on the measurement. The density difference between foam and liquid can be distinguished through a special anti-foam algorithm or filtering technology.

4. Using high-accuracy, high-stability Mono-Si sensitive elements and utilizing fully automated production to effectively reduce unstable factors and ensure that the equipment is always in good oerating condition.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD