LEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. LEEG's hygienic products have obtained the 3A and EHEDG certificates respectively in the USA and Europe. A hygienic pressure transmitter, also known as a sanitary pressure sensor and referred to as a Hygienic Pressure Transmitter/Sanitary Pressure Sensor in English, is designed to ensure the hygiene and safety of food and pharmaceutical products by preventing contact with toxic, harmful, or contaminated substances that could compromise the quality of the products. The materials, structure, performance, and processing (such as welding and polishing, ect.) of the pressure transmitter that comes into direct contact with food and drugs have to meet a series of strict hygiene requirements to qualify as a hygienic pressure transmitter/sensor.

LEEG hygienic monosilicon pressure transmitter meets a series of hygiene requirements, including: selecting different levels of stainless steel materials (304L, 316L, 410, 409, 329) according to different requirements for non-toxicity and harmlessness; ensuring that various polymer materials, rubber elastic materials, adhesives, lubricants, measuring conductive liquid materials, thermal insulation materials, and external coating materials shall not contain toxic or harmful components, no toxic or harmful components leaching or permeating, etc.; requiring a smooth and seamless surface structure that is not easily fouled or contaminated, easy to rinse (often using quick-opening clamp interfaces) and easy to sterilize and disinfect, ect.; requiring strict sealing and isolation to prevent the entry and leakage of toxic, harmful, and contaminated substances, and resistance to high-temperature sterilization and disinfection; requiring a certain degree of cleanliness and weldability in processing; requiring suitable cleaning agents, easy cleaning of internal and external surfaces, and easy in-situ cleaning (CIP) and in-situ sterilization (SIP) in maintenance.

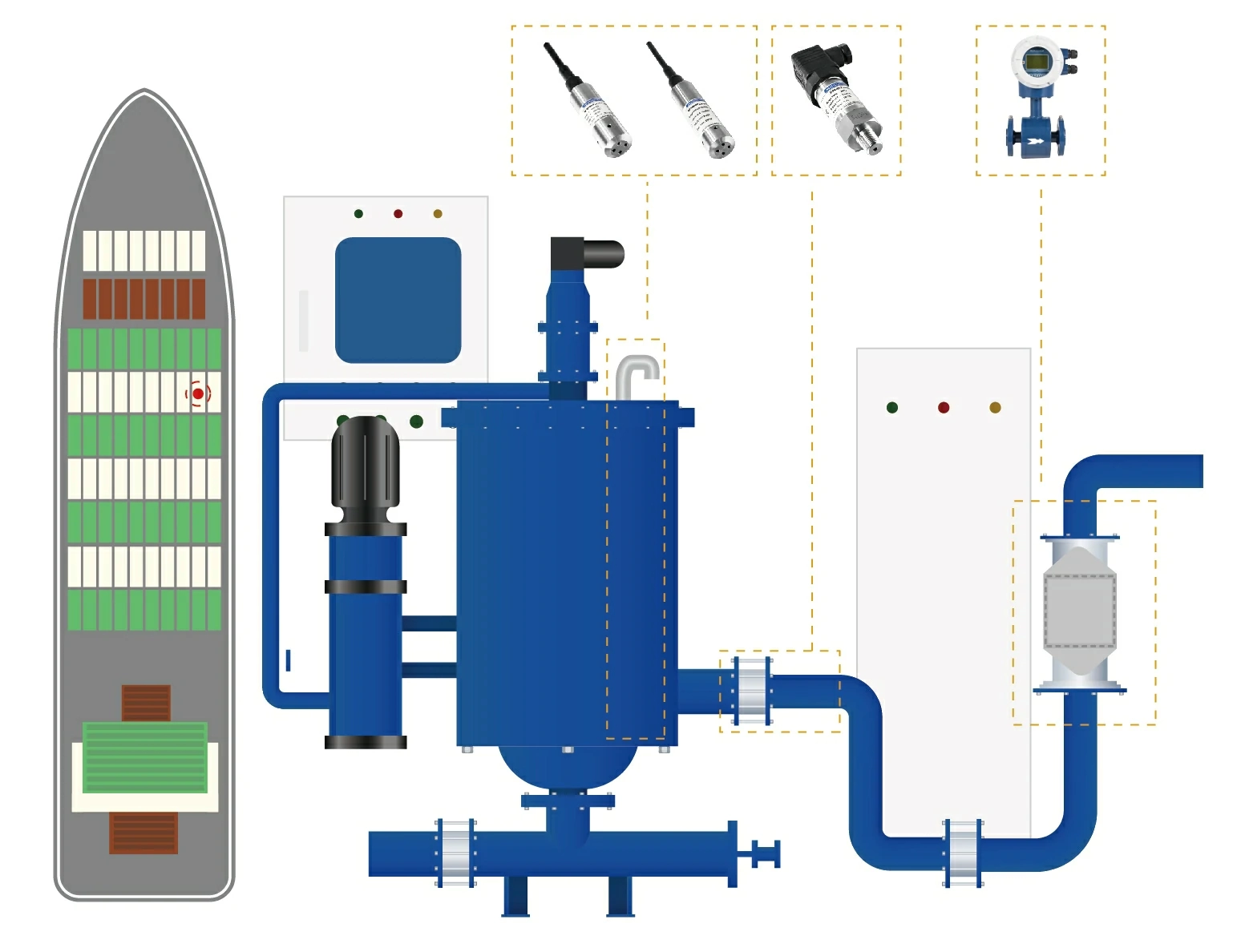

LEEG hygienic monosilicon pressure transmitter is used in food and drug manufacturing equipment to directly contact food and drug raw and auxiliary materials, semi-finished and finished products for pressure, level and temperature measurement. It uses high-quality stainless steel material and integrated welding structure, and meets strict sealing isolation performance and has the ability to withstand strict and sufficient high temperature sterilization or chemical sterilization. It is not easy to create dead corners for sterilization during installation and use, meeting the requirements of asepsis and avoiding contamination, thereby ensuring the safety of food and drug production.

Features

• Designed for food and pharmaceutical

• Measuring viscous, particulatescontaining and contaminated media

• Working temperature: -40-85℃, integrated LCD display: -20-70℃

• International standard process connections are available

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD