Hygienic Pressure Transmitter

Pressure type: Gauge

Range: 0.1bar~30bar

Output signal: 4~20mA, 4~20mA+HART

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

LG200-FRF

Used For

Pharmaceutical, Medical, Fermentation, Beverage, Dairy, Beer, and Food Industries

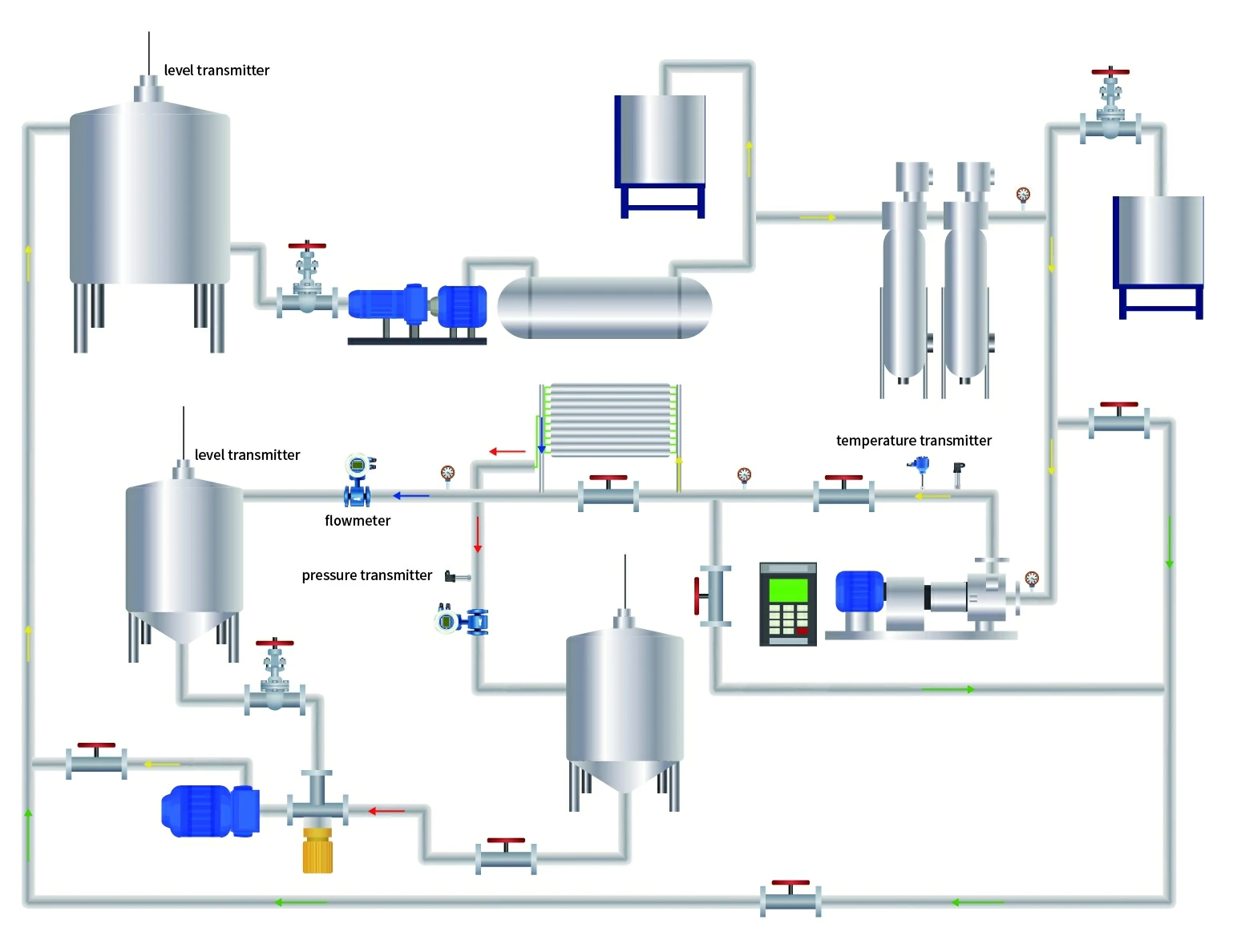

Leave a MessageLEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. LEEG's hygienic products have obtained the 3A and EHEDG certificates respectively in the USA and Europe. The LG200-FRF hygienic temperature transmitter adopts a signal transmission module with dedicated integrated circuits and surface packaging technology, and optionally built-in LCD display module with backlight and button operation. The Integrated transient-resistant terminal block meets Class IV standard (differential mode voltage: 2000V, common mode voltage: 4000V), applicable to harsh surge voltage situations. The LG200-FRF hygienic temperature transmitter provides a flexible and reliable solution for any temperature measurement condition.

Feature

• ASIC&SMT signal transmitting module

• Solution for any temperature measurement

• Easy mounting on pipe、tube

Specification

• Measuring range: -50 - 400℃

• Working temperature: -40-85℃

• Output signal: 4-20mA

• Reference accuracy: ±0.5% URL

• Measuring medium: The fluid which compatible with wetted parts

Image:

LEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. LEEG's hygienic products have obtained the 3A and EHEDG certificates respectively in the USA and Europe. The LG200-FRF hygienic temperature transmitter adopts a signal transmission module with dedicated integrated circuits and surface packaging technology, and optionally built-in LCD display module with backlight and button operation. The Integrated transient-resistant terminal block meets Class IV standard (differential mode voltage: 2000V, common mode voltage: 4000V), applicable to harsh surge voltage situations. The LG200-FRF hygienic temperature transmitter provides a flexible and reliable solution for any temperature measurement condition.

Feature

• ASIC&SMT signal transmitting module

• Solution for any temperature measurement

• Easy mounting on pipe、tube

Specification

• Measuring range: -50 - 400℃

• Working temperature: -40-85℃

• Output signal: 4-20mA

• Reference accuracy: ±0.5% URL

• Measuring medium: The fluid which compatible with wetted parts

Pressure type: Gauge

Range: 0.1bar~30bar

Output signal: 4~20mA, 4~20mA+HART

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

Pressure type: Gauge

Range: 0.1bar~25bar

Output signal: 4~20mA, 4~20mA+HART, Modbus-RTU/RS485 and others

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

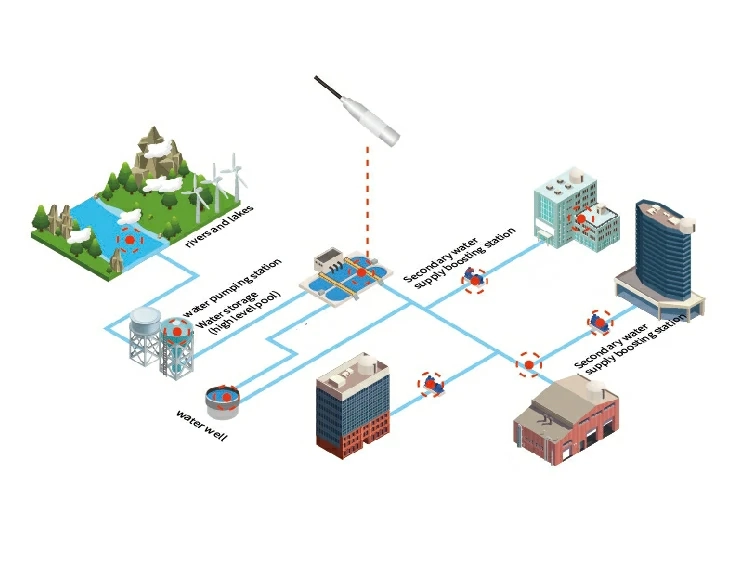

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

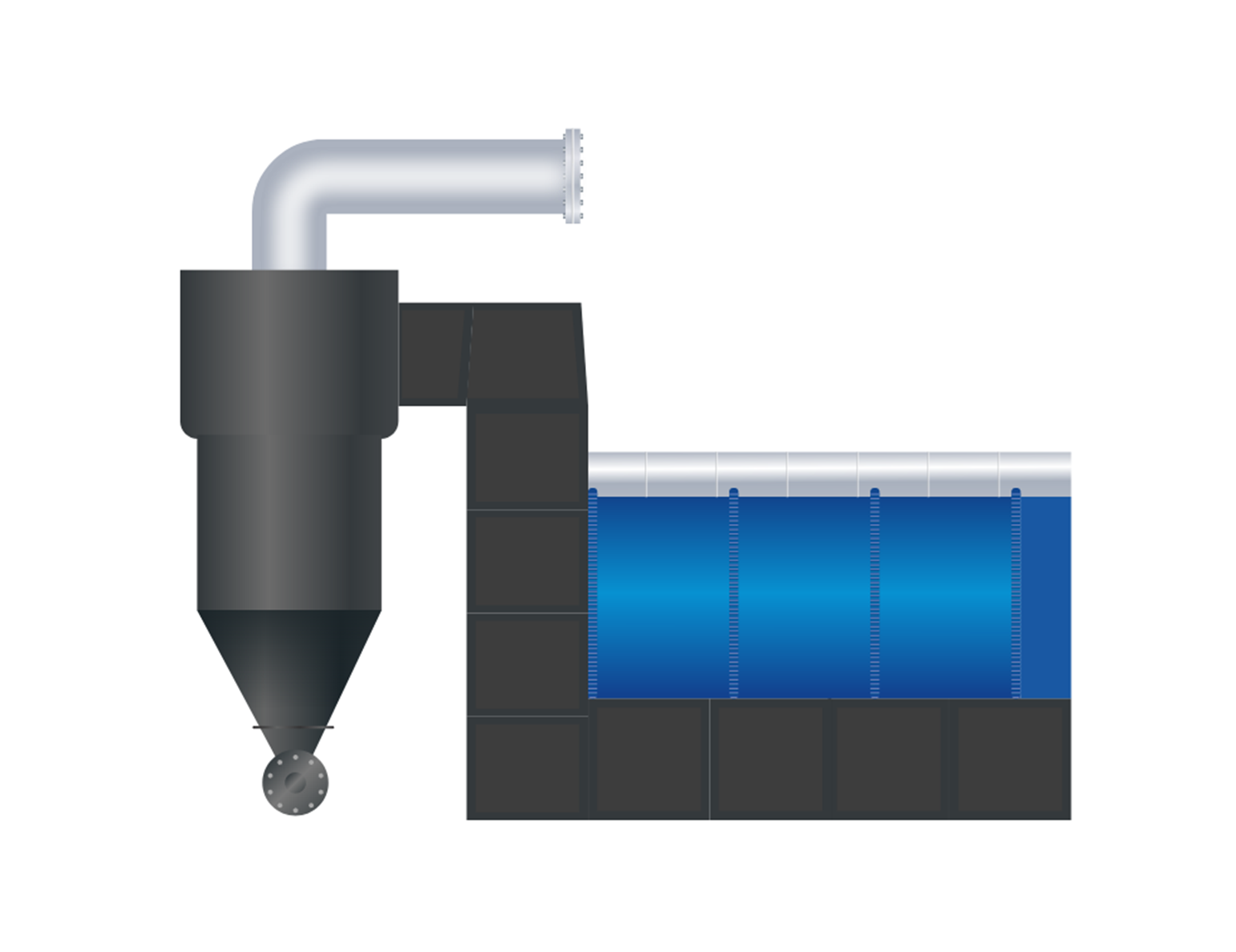

In the paper industry, the alkali recovery system is an essential part that operates under harsh conditions. The system needs strong pressure, temperature, and flow instrumentation to handle high temperatures, high pressures, and corrosive media.

more info...

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...

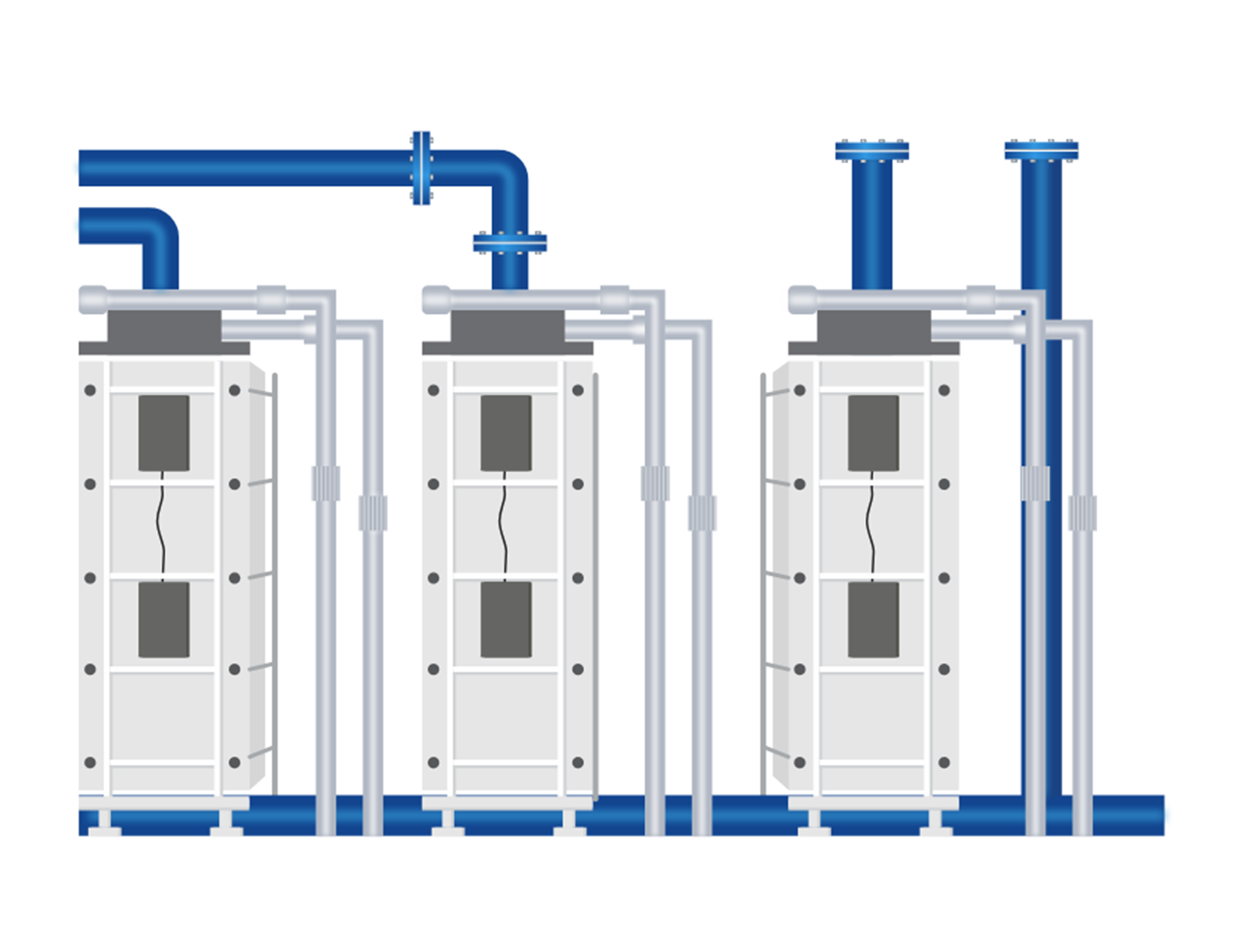

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...