WZ Temperature Sensor

Temperature range: -200℃~ 0℃ …1300℃

Explosion-proof

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MTM

Used For

· Temperature Measurement for Petroleum, Chemical, Metallurgy, Power Station and Light Industry

Leave a MessageMTM is an integrated temperature transmitter with various output forms and easy installation. MTM can measure various media from -200 ℃ to 500 ℃, such as liquids, gases and solid surfaces. The temperature sensing element is linearly corrected through a proprietary temperature module. Supports diversified output of analog signals and digital signals. The product structure is made of all stainless steel and is corrosion-resistant. Customized solutions to meet different temperature measurement needs.

Feature

• Optional Output Form, Supports Customization

• Cost-effective and Easily Installed

• All Stainless Steel Material, Compact Structure

Specifications

• Power Supply: 10V ~ 30V DC, 15V ~ 30V DC(with indicator)

• Output: 4mA ~ 20mADC, RS485, HART

• Accuracy: ±1.0%FS

• Insulation Resistance: ≥20MΩ@500V DC

• Circuit Operation Temperature: -10℃~ 80℃

• Medium Temperature: -200℃~ 500℃

• Indicator Temperature: -10℃~ 60℃

• Protection: IP65

• Housing: Aluminum Alloy (water-proof connection box)

• Wetted Part: Stainless Steel 304,316L or others

• Sensing Element: PT100,PT1000 or others

Image:

MTM is an integrated temperature transmitter with various output forms and easy installation. MTM can measure various media from -200 ℃ to 500 ℃, such as liquids, gases and solid surfaces. The temperature sensing element is linearly corrected through a proprietary temperature module. Supports diversified output of analog signals and digital signals. The product structure is made of all stainless steel and is corrosion-resistant. Customized solutions to meet different temperature measurement needs.

Feature

• Optional Output Form, Supports Customization

• Cost-effective and Easily Installed

• All Stainless Steel Material, Compact Structure

Specifications

• Power Supply: 10V ~ 30V DC, 15V ~ 30V DC(with indicator)

• Output: 4mA ~ 20mADC, RS485, HART

• Accuracy: ±1.0%FS

• Insulation Resistance: ≥20MΩ@500V DC

• Circuit Operation Temperature: -10℃~ 80℃

• Medium Temperature: -200℃~ 500℃

• Indicator Temperature: -10℃~ 60℃

• Protection: IP65

• Housing: Aluminum Alloy (water-proof connection box)

• Wetted Part: Stainless Steel 304,316L or others

• Sensing Element: PT100,PT1000 or others

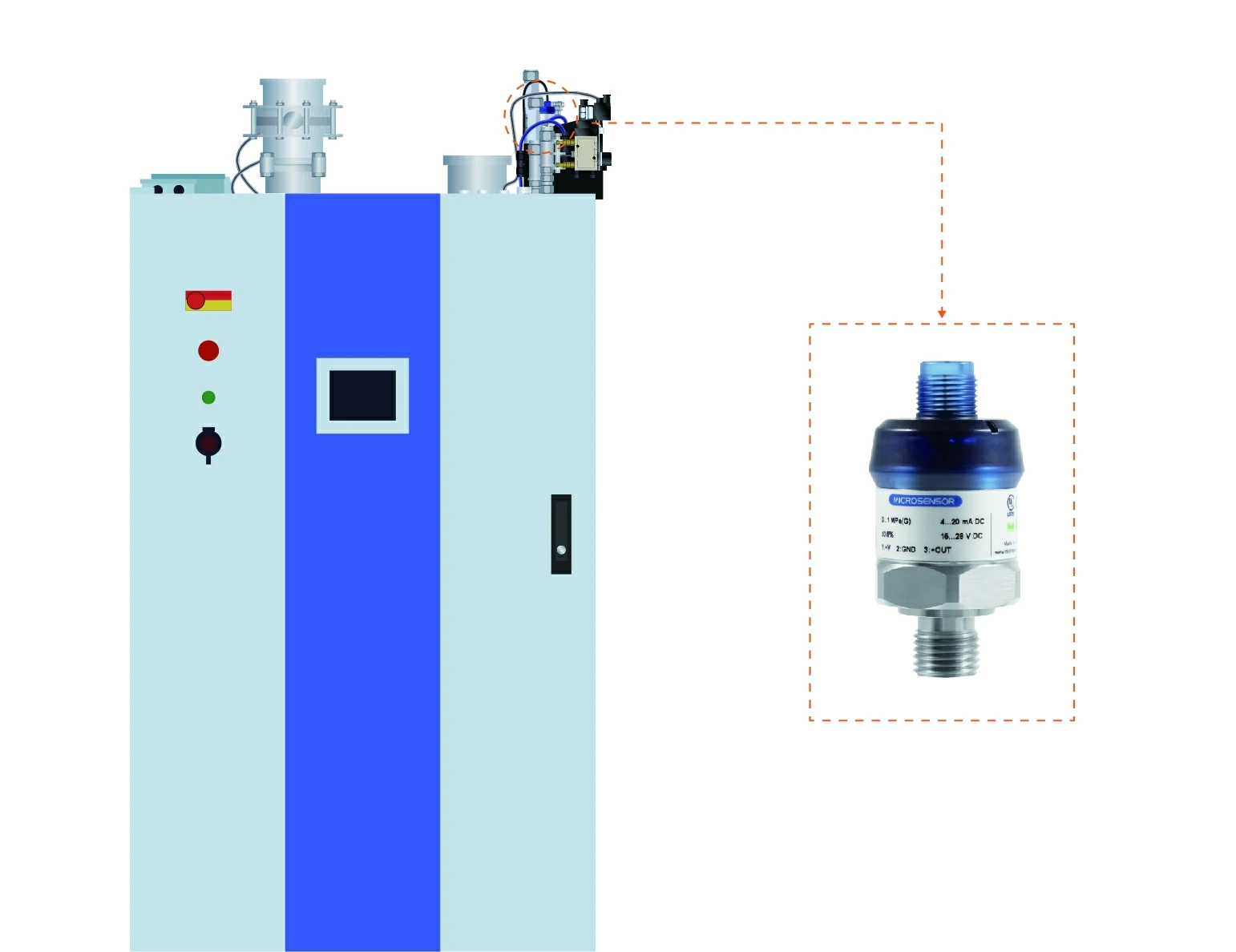

Inkjet printers are common equipment in the packaging and printing industry. Utilizing continuous inkjet technology, real-time pressure monitoring and early warning are necessary to ensure continuous and stable ink ejection, guaranteeing print quality.

more info...

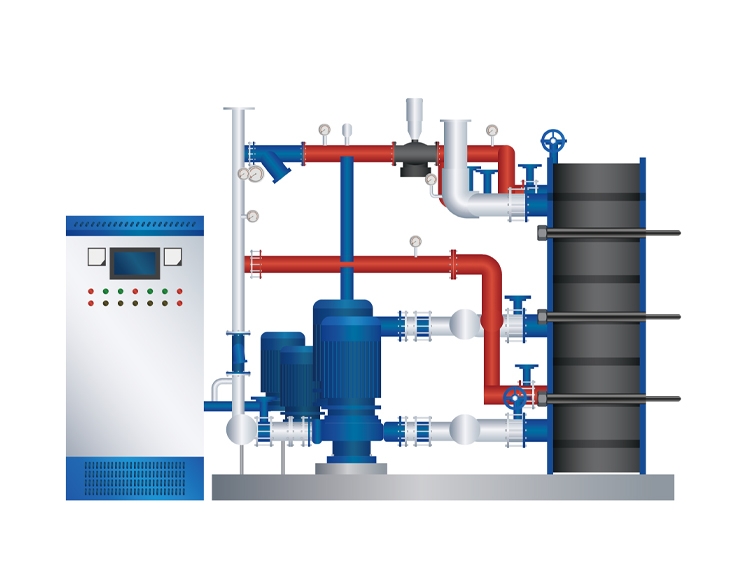

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...

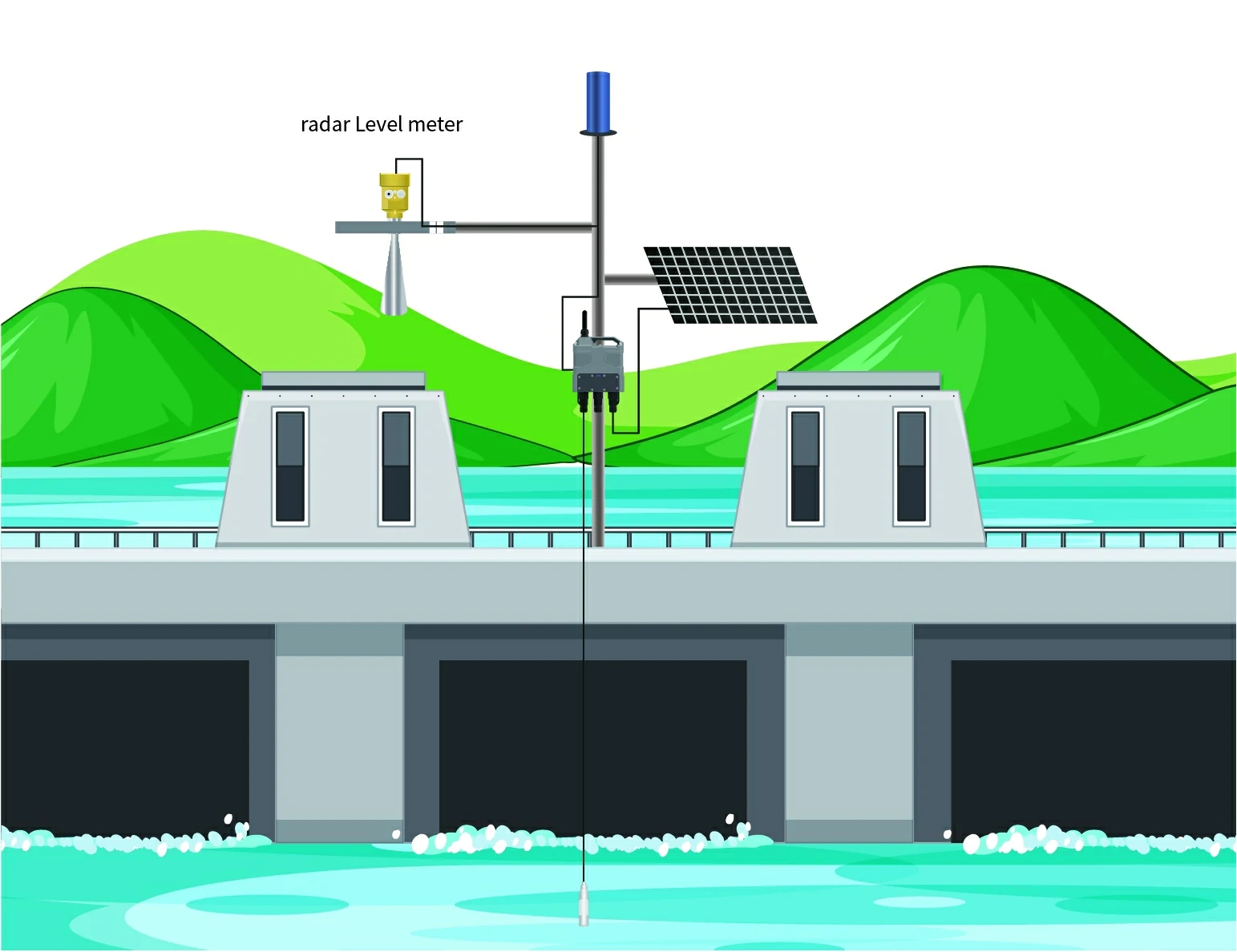

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

The plasma in a plasma cleaning machine is a state of matter, usually composed of process gases. Therefore, specially designed pressure transmitters must be installed in the relevant gas circuits of the plasma cleaning system to monitor and provide feedback on production data.

more info...