Flush Diaphragm Pressure Sensor

M20x1.5, R1/2, G1/2

0bar~1bar...35bar

Flush Diaphragm

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

WZ

Used For

Chemical, Pharmaceutical, Electric Power, Metallurgy, Papermaking

Leave a MessageWZ series Temperature Sensor capable of directly assessing temperatures across a spectrum that spans from -200°C to 500°C, encompassing liquid, steam, gaseous substances, and solid surfaces in the production process. Generally, the temperature sensor is in tandem with display devices, recording equipment, and electronic regulators. The product is small and easy to install. The contacted material with the medium is corrosion-resistant and can be used in complex environments.

Features

• The sensor is in contact with the measured medium, with high reliability.

• Diversified products can be provided.

• Explosion-proof certification Exd Ⅱ C T6 Gb.

• A variety of indexing numbers are optional.

Usage Recommendation

• PT100 is recommended for application with long-term temperature range less than 300℃.

• PT1000 can be a suitable option when dealing with a narrow measuring range.

• K-type thermocouple is recommended if the long-term temperature is between 300℃ and 800℃.

• S-type thermocouple is recommended if the long-term temperature exceeds about 1200℃.

Image:

WZ series Temperature Sensor capable of directly assessing temperatures across a spectrum that spans from -200°C to 500°C, encompassing liquid, steam, gaseous substances, and solid surfaces in the production process. Generally, the temperature sensor is in tandem with display devices, recording equipment, and electronic regulators. The product is small and easy to install. The contacted material with the medium is corrosion-resistant and can be used in complex environments.

Features

• The sensor is in contact with the measured medium, with high reliability.

• Diversified products can be provided.

• Explosion-proof certification Exd Ⅱ C T6 Gb.

• A variety of indexing numbers are optional.

Usage Recommendation

• PT100 is recommended for application with long-term temperature range less than 300℃.

• PT1000 can be a suitable option when dealing with a narrow measuring range.

• K-type thermocouple is recommended if the long-term temperature is between 300℃ and 800℃.

• S-type thermocouple is recommended if the long-term temperature exceeds about 1200℃.

1 2 5 10 20mH2O;

Accuracy: +0.25%FS (typ.) +0.5%FS(max.);

4~20mADC;0~10/20mADC;0/1~5/10VDC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:0bar~1bar…1000bar

LCD Indicator

Battery Power Supply

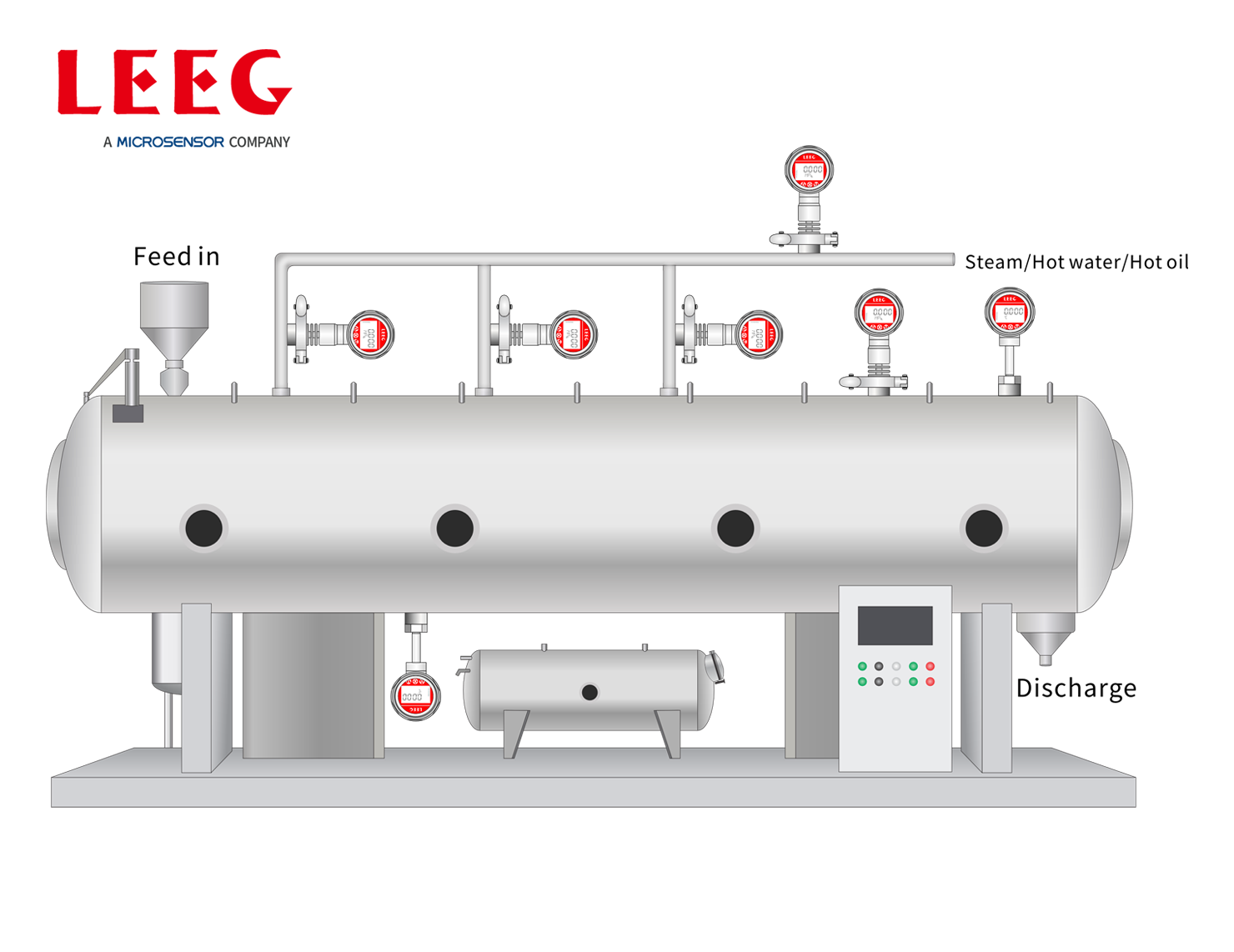

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

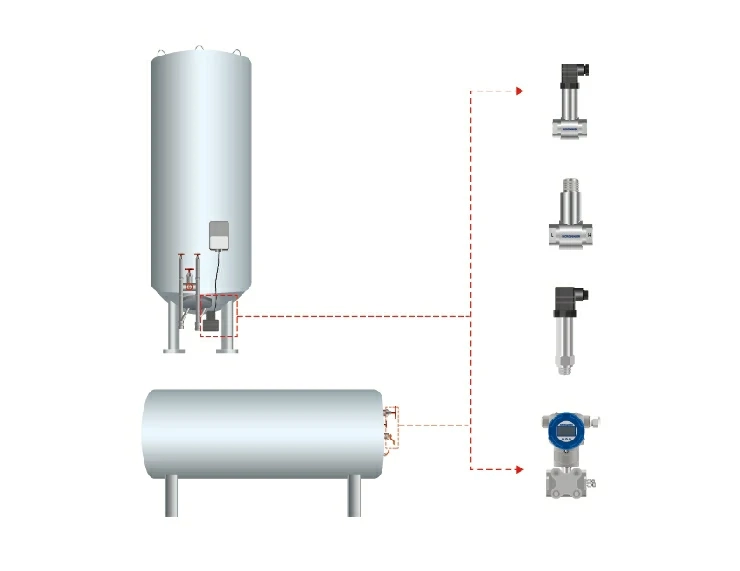

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

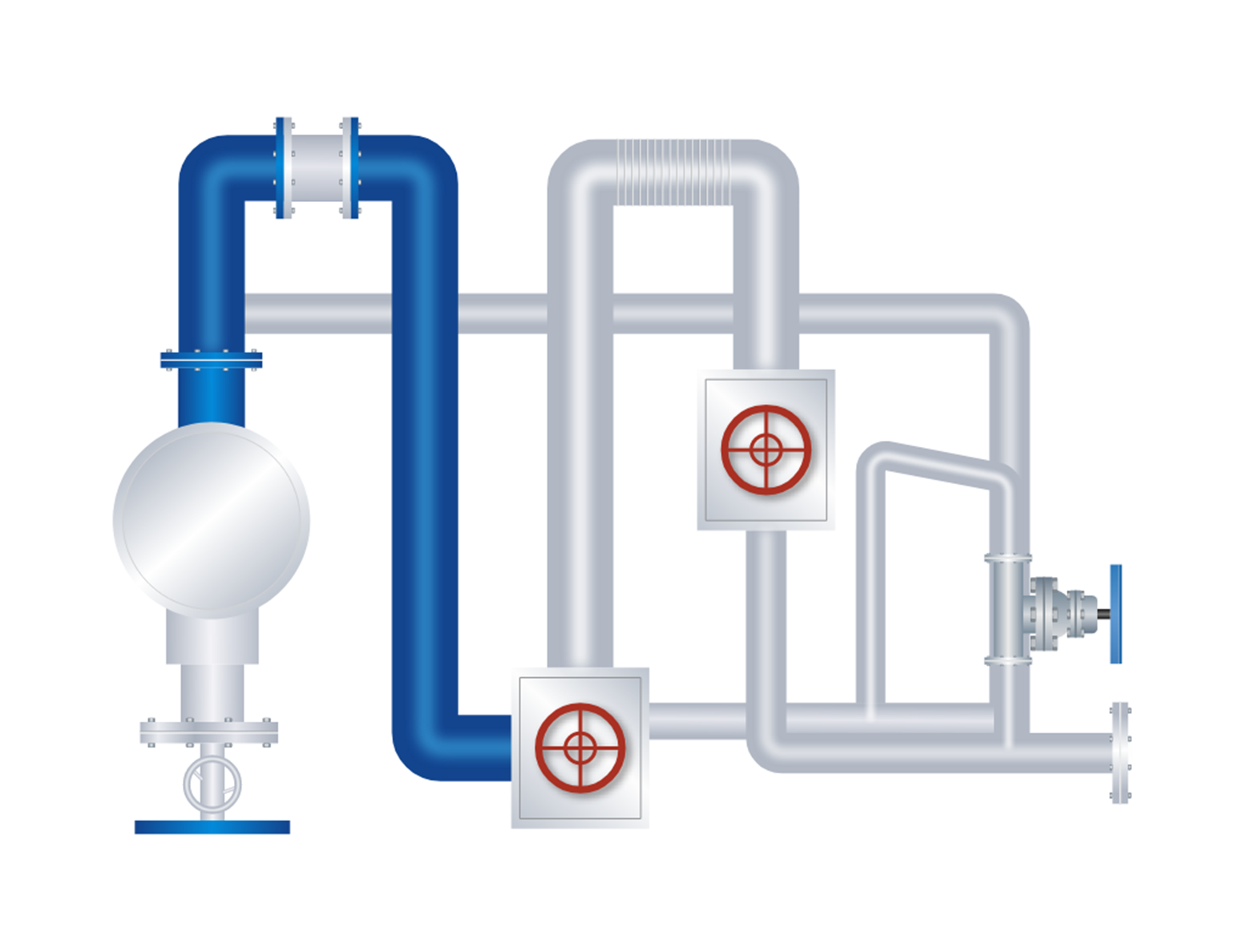

The paper machine's drying section employs steam-heated cylinders, with steam generated by a separate boiler and transported by pipelines. To ensure optimal steam supply, a differential pressure transmitter with an orifice plate is used to measure flow, allowing for accurate planning.

more info...

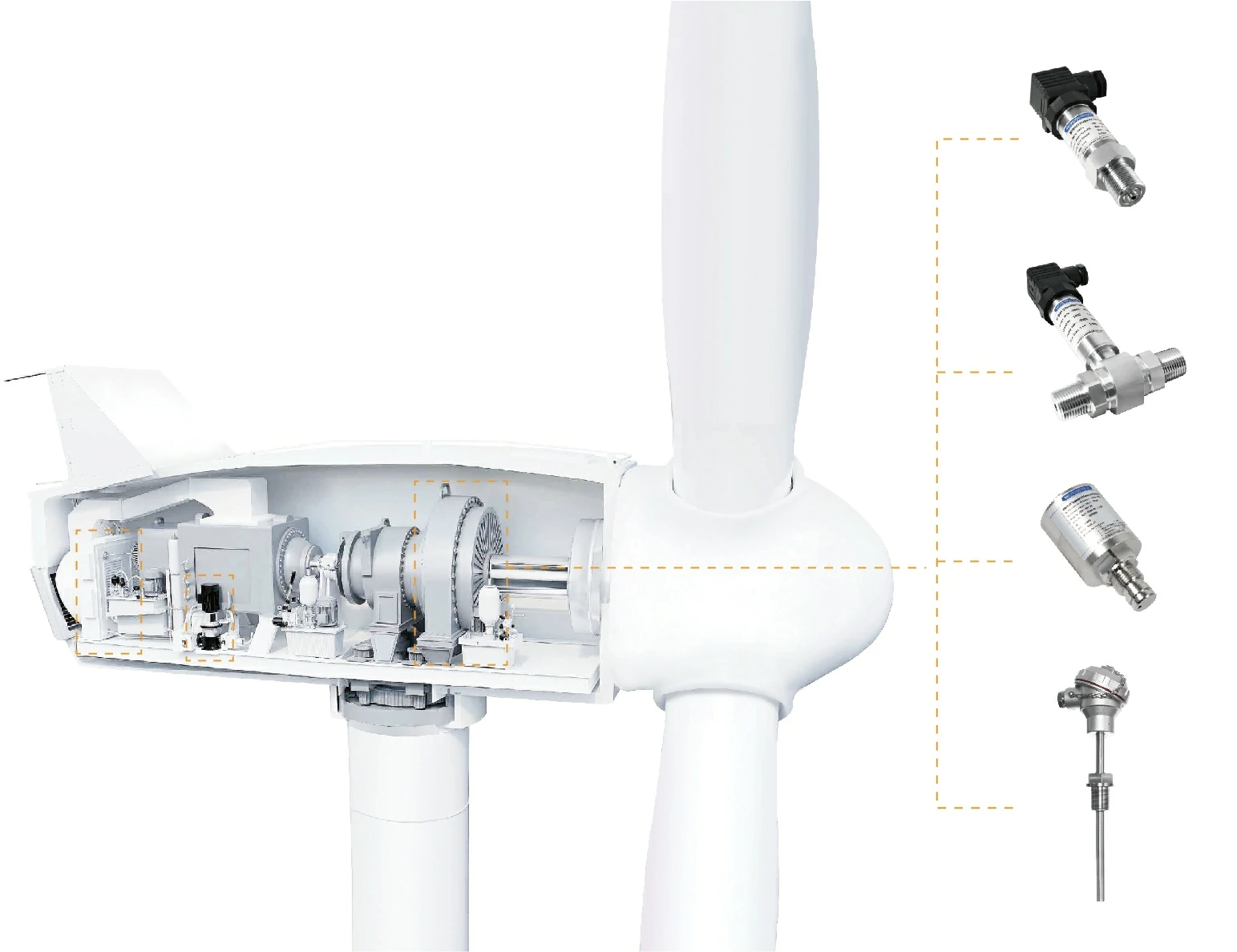

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...