Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM4881W

Used For

Equipment Automatic Pressure Detection, Action Control and Water Level Alarm, Long-Distance Pressure Measurement and Control

Leave a MessageMPM4881W is IP68 protected Level Transmitting Controller with local LED display. The product adopts the internationally advanced ARM processing chip. By compensating and adjusting the sensor, it can achieve precise measurement and provide quick response and control of multiple relays.

MPM4881W provides 5-relay output + 1 analog output. The meter supports peak record and action delay, providing 4 digit LED indicator, easy for reading. And the design of multiple buttons makes the operation easier and more convenient. Either current or voltage output signal is optional.

Features

• Level measurement for liquid media

• 14-segment LED display

• Support rail, cover, back mounting

• ModBus communication and button programming, easy operation.

• Max. 5 relays control independently, time-delay function

• Switchable analog output

• Record the Max. in operation(button for clearing up)

Specifications

• Input Power Supply: (220±44)V AC / 22V~32V DC

• Level Range: 1m, 2m, 5m, 10m, 20m, 50m, 100m, 200mH2O

• Overpressure: 1.5 FS

• Output Accuracy: ≤±0.5%FS

• Repeatability: ≤±0.2%FS

• Display: 4 digit 0.56 inch 14-segment LED display

• Display Refresh: 200ms

• Thermal Drift: ≤±0.03%FS/℃ (Zero/FS)

• Resolution: 0.1cm

Image:

MPM4881W is IP68 protected Level Transmitting Controller with local LED display. The product adopts the internationally advanced ARM processing chip. By compensating and adjusting the sensor, it can achieve precise measurement and provide quick response and control of multiple relays.

MPM4881W provides 5-relay output + 1 analog output. The meter supports peak record and action delay, providing 4 digit LED indicator, easy for reading. And the design of multiple buttons makes the operation easier and more convenient. Either current or voltage output signal is optional.

Features

• Level measurement for liquid media

• 14-segment LED display

• Support rail, cover, back mounting

• ModBus communication and button programming, easy operation.

• Max. 5 relays control independently, time-delay function

• Switchable analog output

• Record the Max. in operation(button for clearing up)

Specifications

• Input Power Supply: (220±44)V AC / 22V~32V DC

• Level Range: 1m, 2m, 5m, 10m, 20m, 50m, 100m, 200mH2O

• Overpressure: 1.5 FS

• Output Accuracy: ≤±0.5%FS

• Repeatability: ≤±0.2%FS

• Display: 4 digit 0.56 inch 14-segment LED display

• Display Refresh: 200ms

• Thermal Drift: ≤±0.03%FS/℃ (Zero/FS)

• Resolution: 0.1cm

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

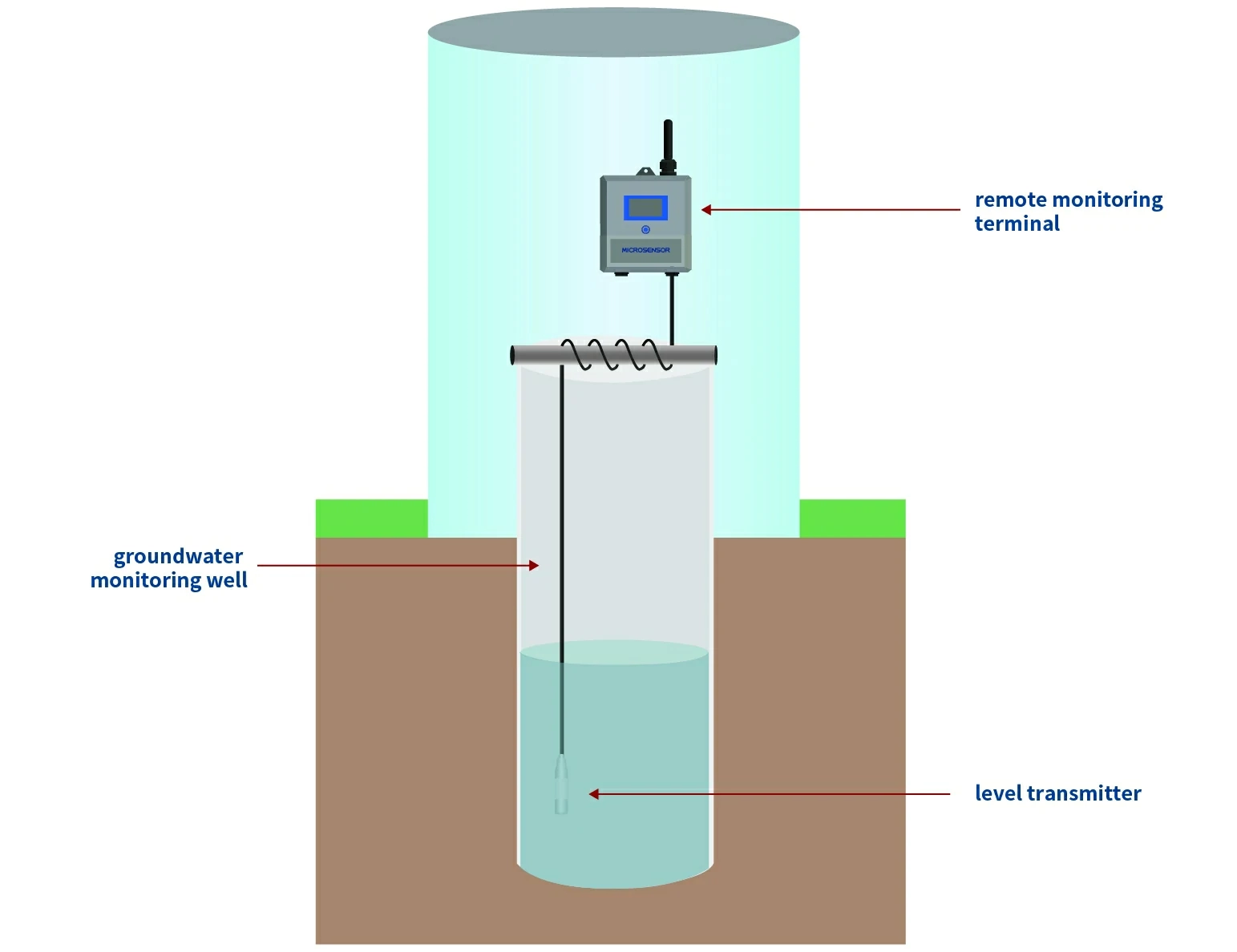

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

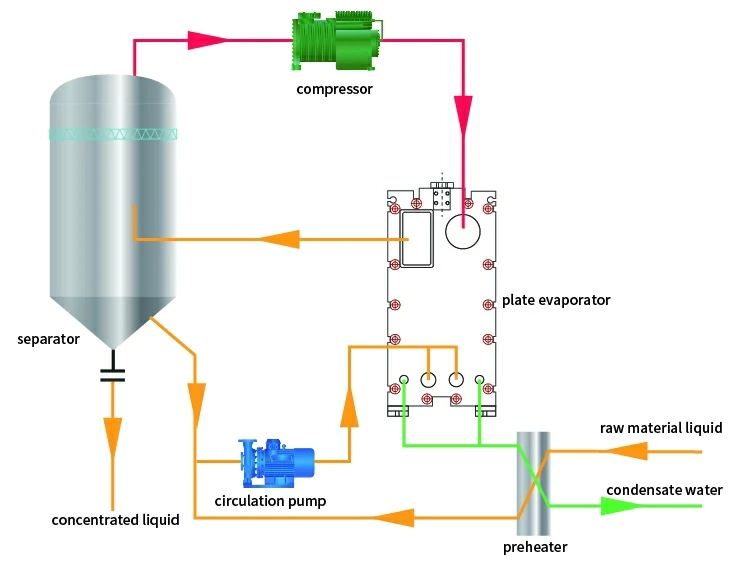

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

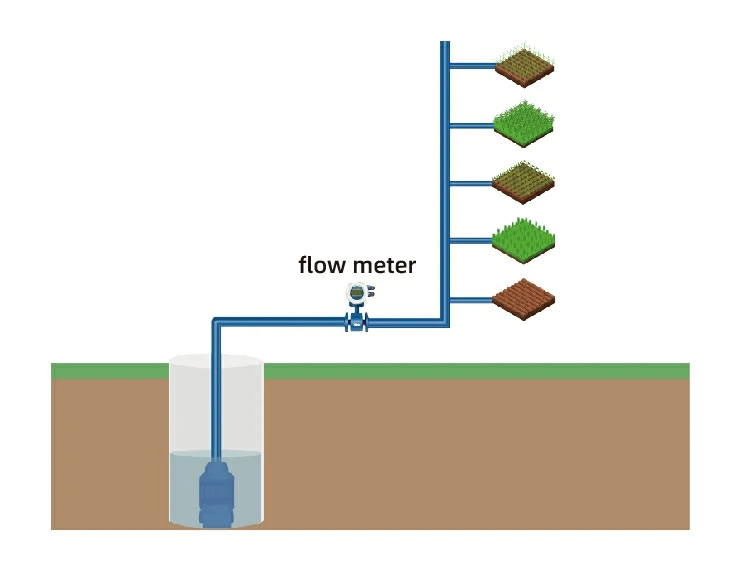

Pipelines are the most common water transportation and irrigation facilities. During transportation, pipelines effectively reduce evaporation and leakage of water resources. Monitoring instruments measure accurately discharge flow. It is a crucial action of rational water resource allocation and reasonable water fee collection.

more info...

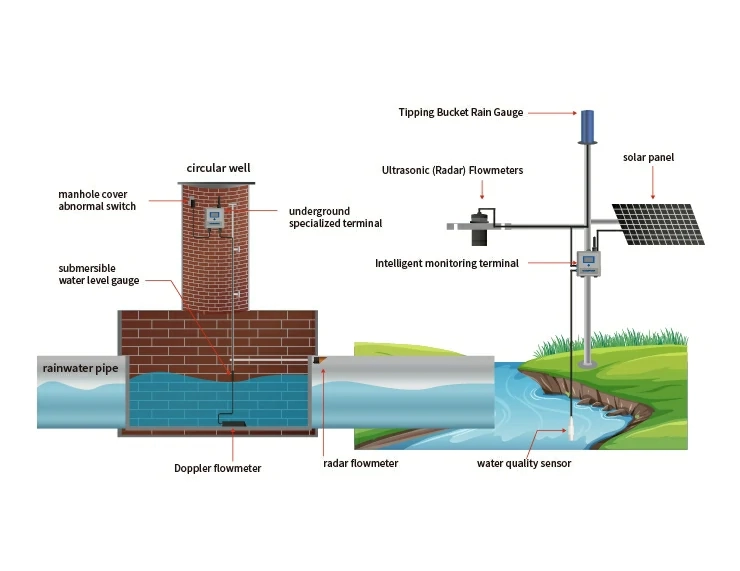

Pressure, level, and flow measurements at the rainwater outlet ensure stable drainage. Monitoring instruments help detection and early warning of pipe burst incidents in time.

more info...