Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4710

Used For

Petrochemical, Water Management, City Water Supply and Drainage

Leave a MessageMPM4710 recording transmitter completely records pressure, temperature and the happening time. It uses the latest microprocessing technique for better accuracy and resolution for pressure and temperature signals. The SS316 enclosure protects the sensor against corrosion, impact and water ingress. 3.6VDC lithium battery of 7 year life can record up to 50000 reads.

Features

• Easy to change battery and read data

• Working Environment Temp.: -30℃ ~80℃

• Low power consumption, capable of submersible use for many years

• High stability; Good data security

• Maximum 50,000 records

• Restore factory settings available

• Microprocessing technology ensures higher accuracy and resolution of pressure and temperature signals

Note

• When not working, do not connect the power supply and cables to the transmitter.

• Pay attention to atmospheric changes; it is recommended to install a barometer or another MPM4710 to record the air pressure.

Image:

MPM4710 recording transmitter completely records pressure, temperature and the happening time. It uses the latest microprocessing technique for better accuracy and resolution for pressure and temperature signals. The SS316 enclosure protects the sensor against corrosion, impact and water ingress. 3.6VDC lithium battery of 7 year life can record up to 50000 reads.

Features

• Easy to change battery and read data

• Working Environment Temp.: -30℃ ~80℃

• Low power consumption, capable of submersible use for many years

• High stability; Good data security

• Maximum 50,000 records

• Restore factory settings available

• Microprocessing technology ensures higher accuracy and resolution of pressure and temperature signals

Note

• When not working, do not connect the power supply and cables to the transmitter.

• Pay attention to atmospheric changes; it is recommended to install a barometer or another MPM4710 to record the air pressure.

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

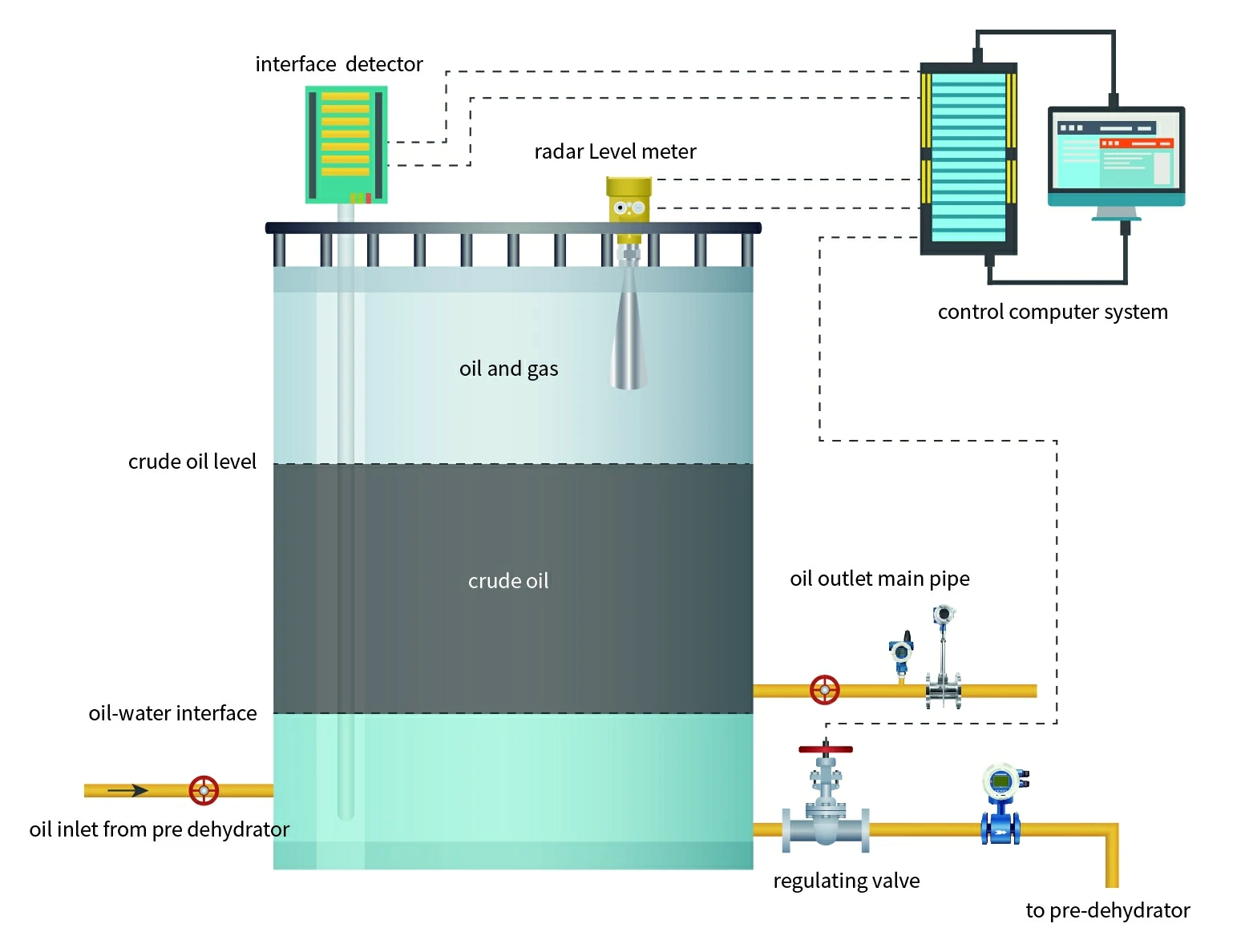

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

Rotary gas meter is the critical equipment in the system of urban gas gate station. As the basis of gas billing, rotary gas meter can accurately calculate the flow of natural gas. It is equipped with pressure transmitter with high accuracy, so as to guarantee the flow accuracy.

more info...

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...