Pressure and Temperature Sensor

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

MPM283VI

Used For

Industrial Process Control, Pressure Measuring Instruments, Refrigeration Equipments and Air Conditioning Systems

Leave a MessageMPM283VI thread connected pressure sensor uses a high-precision, high-stability sensor chip. The MPM283VI production line adopts advanced automation equipment and automatic testing. The pressure sensor product is compact and easy to connect. The M14x1.5 thread is consistent with the general sensor products and has the characteristics of good interchangeability. The measurement range of MPM283Ⅵ is 0bar~100bar...1000bar, which can be specially used for medium and high pressure measurement.

Features

• Φ12.6mm compact size OEM pressure sensor

• M14×1.5 Thread

• Measure various fluid media

• Gauge, Absolute and Sealed gauge optional

• Stainless steel 316L or Hastelloy C materials

Electrical Performance

• Output impedance: 3.5kΩ ~ 6kΩ

• Response (10% ~ 90%): < 1ms

• Overpressure: 2 times FS or 1100bar (min. value is valid)

• Housing: Stainless steel 316L

• Electrical connection: Kovar or Silicon rubber flexible wires

• O-ring: FKM

• Net weight: ~8g

Image:

MPM283VI thread connected pressure sensor uses a high-precision, high-stability sensor chip. The MPM283VI production line adopts advanced automation equipment and automatic testing. The pressure sensor product is compact and easy to connect. The M14x1.5 thread is consistent with the general sensor products and has the characteristics of good interchangeability. The measurement range of MPM283Ⅵ is 0bar~100bar...1000bar, which can be specially used for medium and high pressure measurement.

Features

• Φ12.6mm compact size OEM pressure sensor

• M14×1.5 Thread

• Measure various fluid media

• Gauge, Absolute and Sealed gauge optional

• Stainless steel 316L or Hastelloy C materials

Electrical Performance

• Output impedance: 3.5kΩ ~ 6kΩ

• Response (10% ~ 90%): < 1ms

• Overpressure: 2 times FS or 1100bar (min. value is valid)

• Housing: Stainless steel 316L

• Electrical connection: Kovar or Silicon rubber flexible wires

• O-ring: FKM

• Net weight: ~8g

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

Range: -1bar…0bar~0.35bar…35bar

Output signal: Digital I²C (pressure, temperature)

Range: -1bar…-0.35bar ~ 0bar ~0.35bar…700bar

No need for re-calibration for users, high precision

Customizable dimensions

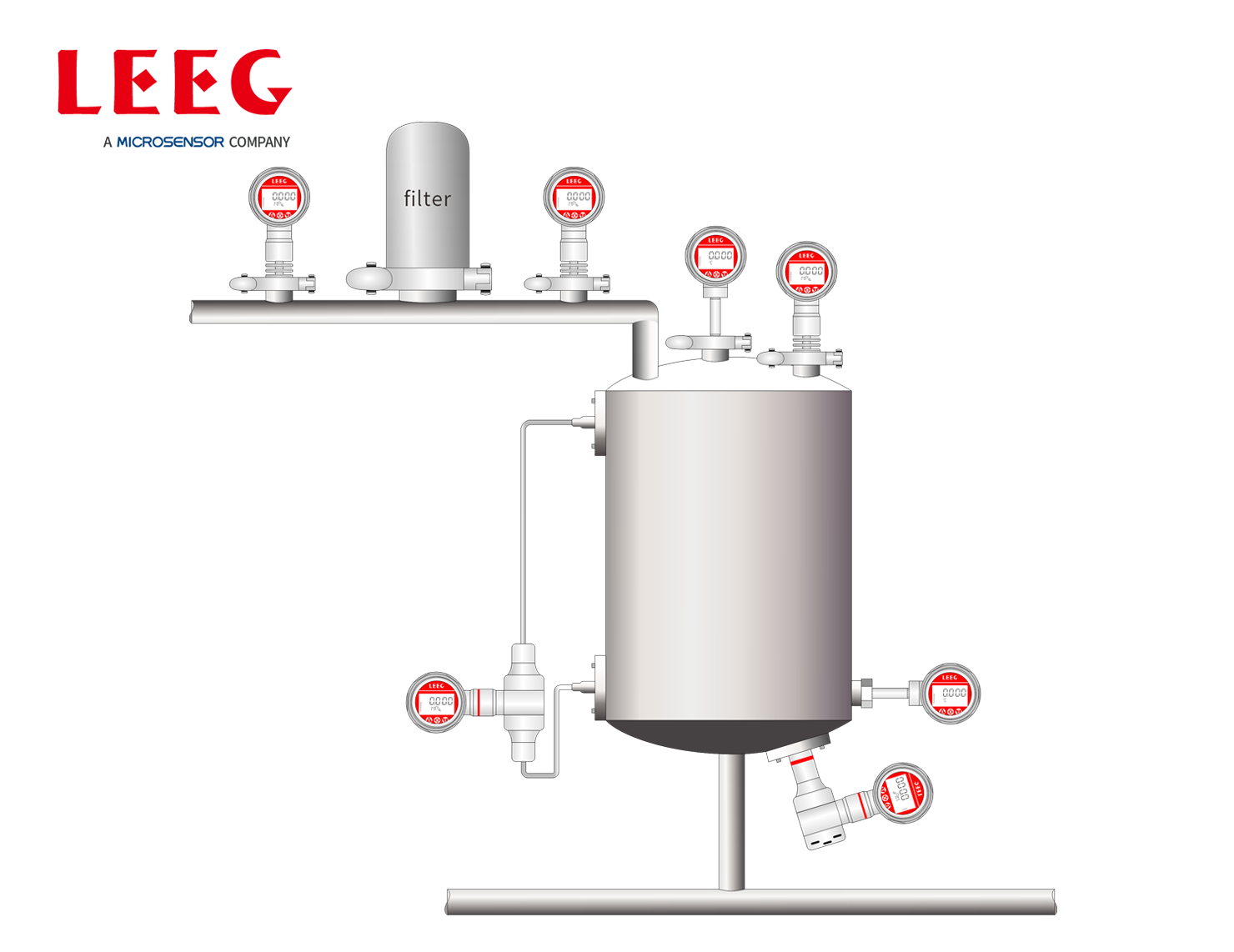

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...

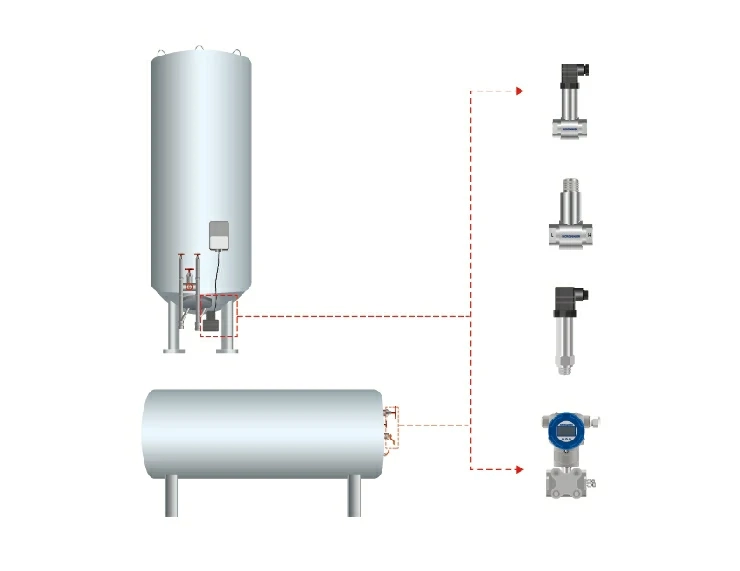

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

Inkjet printers are common equipment in the packaging and printing industry. Utilizing continuous inkjet technology, real-time pressure monitoring and early warning are necessary to ensure continuous and stable ink ejection, guaranteeing print quality.

more info...