Flush Diaphragm Pressure Sensor

M20x1.5, R1/2, G1/2

0bar~1bar...35bar

Flush Diaphragm

SPH19S

Used For

Pressure and Level Measurement for Gas and Liquid , Pressure Calibrators, Hydraulic Systems

Leave a MessageLEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. SPH19S is a piezoresistive pressure sensor with isolated construction and precise compensation. It uses high stable monosilicon sensor die. Stainless steel 316L housing with diameter Ф19mm. Wider temperature compensation and zero correction are calibrated by laser trimming techniques. The measured pressure is transmitted onto the silicon die through 316L diaphragm and inner sealed silicon oil, to transform the pressure to the electric signal. The sensor die doesn't contact the measuring medium directly, forming an isolated structure, suitable for various liquid media. Discover more pressure sensor models and types of Micro Sensor.

Features

• High stability piezoresistive sensor die

• Constant current and voltage excitation

• Isolated structure, suitable for various fluid

• 316L stainless steel

• Hastelloy C, Tantalum

• φ19mm standard/OEM sensing element

Electrical Performance

• Power supply: 0.8-2.0mA, 5-12VDC

• Electrical connection: φ0.5mm kovar pin or 100mm silicone rubber soft wire

• Common mode voltage output: 50% of input (typical)

• Bridge resistance: 6k (10kPa, Typical 3.3k ) Ω Ω

• Respond time (10%-90% ): < 1ms

• Insulation resistance: 500M /500VDC Ω

Image:

LEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. SPH19S is a piezoresistive pressure sensor with isolated construction and precise compensation. It uses high stable monosilicon sensor die. Stainless steel 316L housing with diameter Ф19mm. Wider temperature compensation and zero correction are calibrated by laser trimming techniques. The measured pressure is transmitted onto the silicon die through 316L diaphragm and inner sealed silicon oil, to transform the pressure to the electric signal. The sensor die doesn't contact the measuring medium directly, forming an isolated structure, suitable for various liquid media. Discover more pressure sensor models and types of Micro Sensor.

Features

• High stability piezoresistive sensor die

• Constant current and voltage excitation

• Isolated structure, suitable for various fluid

• 316L stainless steel

• Hastelloy C, Tantalum

• φ19mm standard/OEM sensing element

Electrical Performance

• Power supply: 0.8-2.0mA, 5-12VDC

• Electrical connection: φ0.5mm kovar pin or 100mm silicone rubber soft wire

• Common mode voltage output: 50% of input (typical)

• Bridge resistance: 6k (10kPa, Typical 3.3k ) Ω Ω

• Respond time (10%-90% ): < 1ms

• Insulation resistance: 500M /500VDC Ω

Built-in temperature sensor

Three-diaphragm overload construction

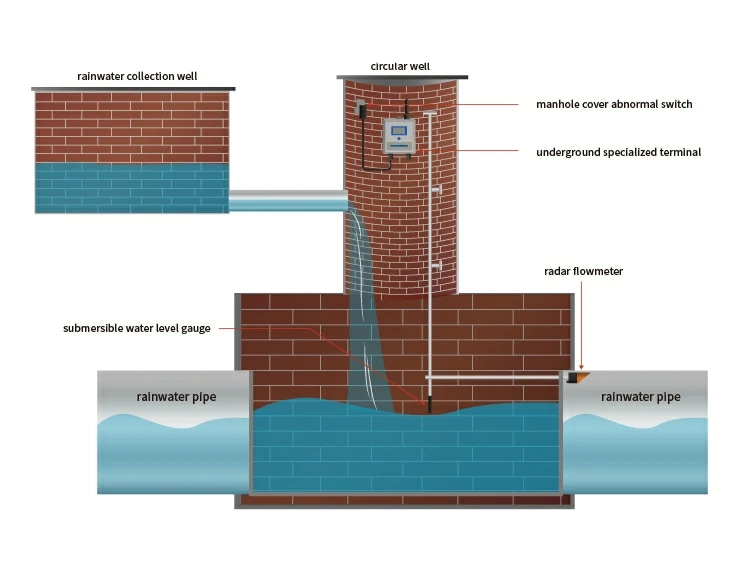

Sump wells are important facilities for convenient daily inspection, prevention, and dredging of drainage pipe blockages. By deploying monitoring instruments at the bottom of the well, a comparison of drainage volume and rainfall is made, allowing for the prediction of flooding points and drainage times under real-time changing drainage conditions. When the water level data exceeds the preset warning value, a timely alarm is given, effectively preventing urban flooding.

more info...

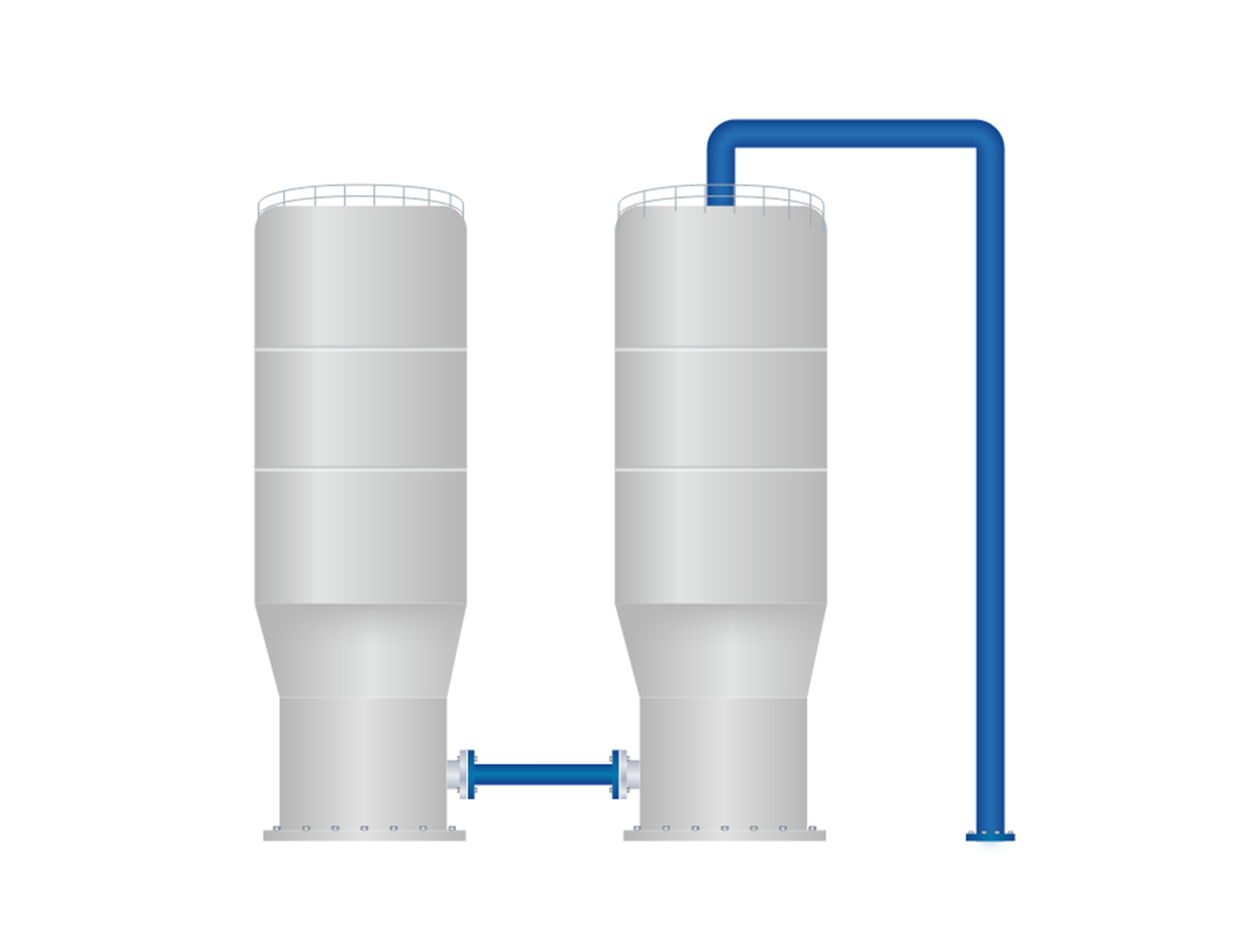

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...

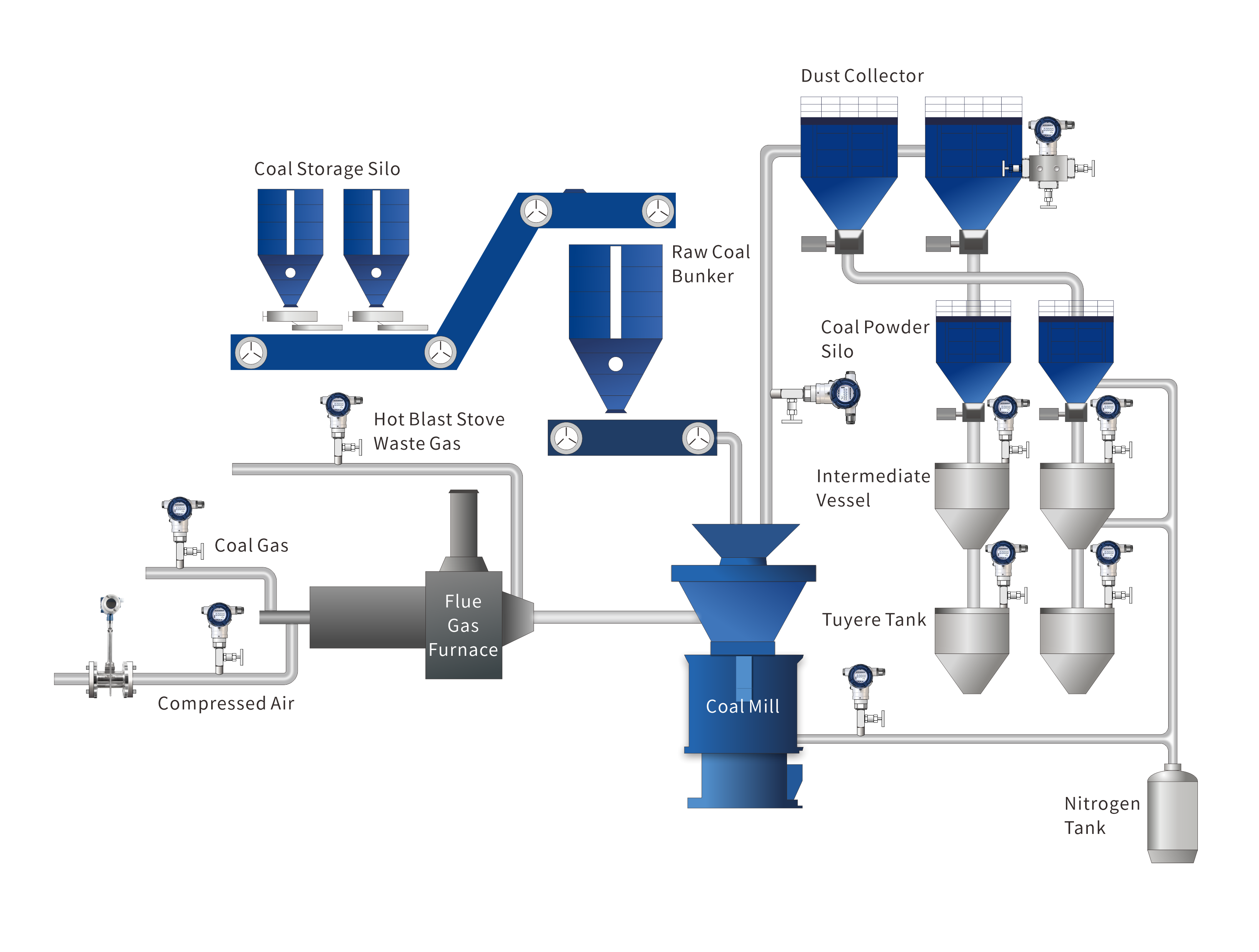

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the metallurgy industry to ensure smelting process efficiency and product quality. In the demanding high-temperature, high-pressure, and harsh environments of the metallurgy industry, Micro Sensor comprehensive monitoring solutions provide real-time data acquisition and precise regulation by integrating smart control systems and advanced sensor technologies. These systems optimize metal production processes for safe and effective operations.

more info...

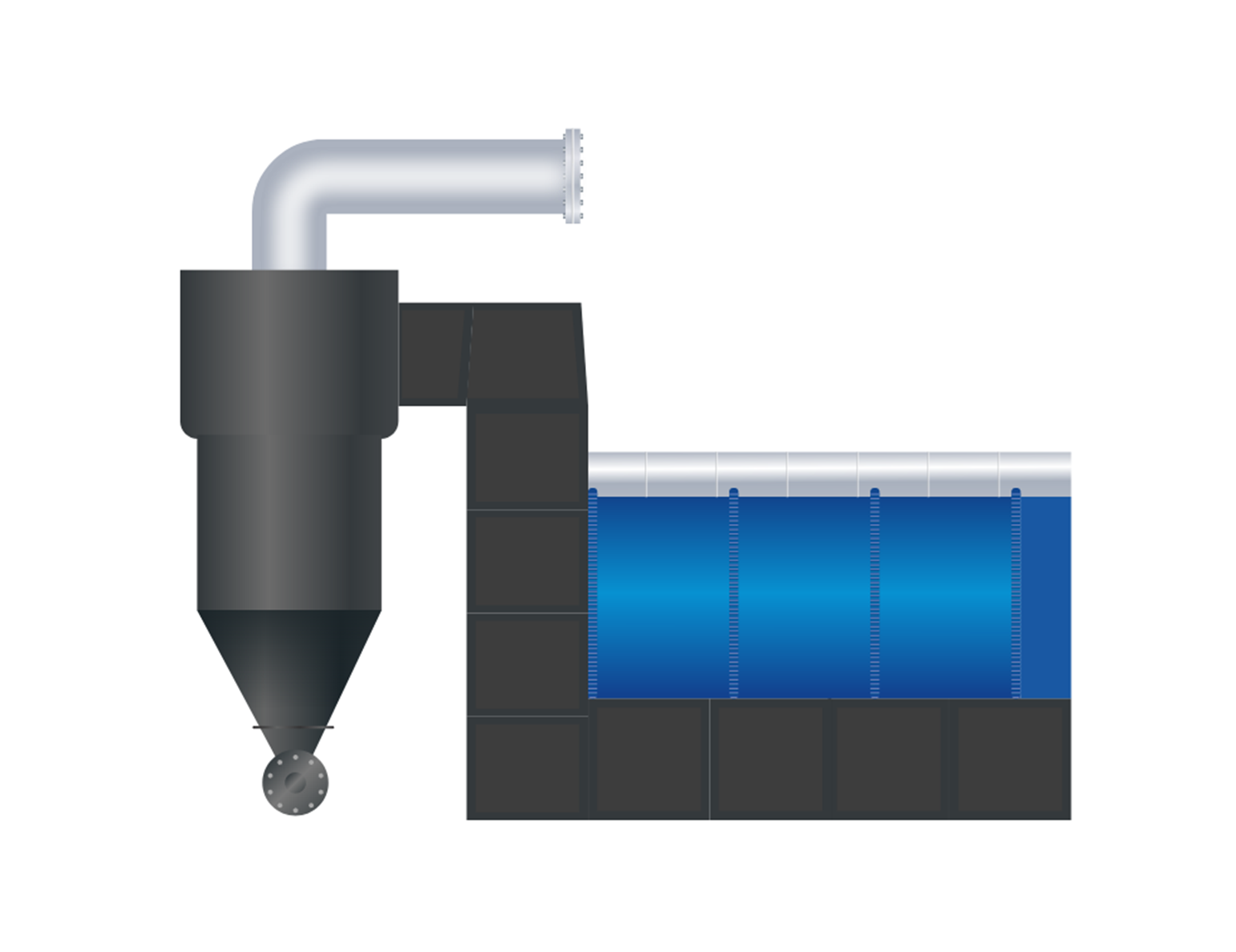

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...