Anti-corrosive Pressure Sensor

Φ19mm

-1bar...0bar~1bar…700bar

Tantalum Diaphragm

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

SP38H

Used For

Process Control, Environmental control, Flow control

Leave a MessageLEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. The SP38H Sensor adopts high-reliability monosilicon technology, with a built-in temperature sensor, which greatly improves the temperature performance. It is a comprehensive digital and smart sensor. It is resistant to high pressure and high static pressure, the static pressure can reach 40MPa. It can be used in various harsh environments, and the working temperature range is as high as -40-85°C. The pressure sensor also has the features of high measurement accuracy, high stability, strong output signal, and good long-term stability.

Features

• Three-diaphragm overload structure

• High long term stability <±0.05% F.S./year

• Extremely low pressure and temperature hysteresis

• Built-in temperature sensor

• Various of isolated diaphragms to meet a wide range of anti-corrosion requirements

• Rugged construction with little effect of repackaging stress

Electrical Performance

• Power supply: 2.5-12VDC

• Electrical connection: 110mm silicone rubber soft wire/Kovar Pins

• Common mode voltage output: 50% of input (typical)

• Bridge resistance: 6kΩ±0.5kΩ

• Response time (10%-90% ): <2ms

• Insulation resistance: >100MΩ@500VDC

• Insulation strength: <5mA/500V AC

Image:

LEEG, a subsidiary of MICROSENSOR, is a leading manufacturer of hygienic transmitters in China's food and pharmaceutical industries. The SP38H Sensor adopts high-reliability monosilicon technology, with a built-in temperature sensor, which greatly improves the temperature performance. It is a comprehensive digital and smart sensor. It is resistant to high pressure and high static pressure, the static pressure can reach 40MPa. It can be used in various harsh environments, and the working temperature range is as high as -40-85°C. The pressure sensor also has the features of high measurement accuracy, high stability, strong output signal, and good long-term stability.

Features

• Three-diaphragm overload structure

• High long term stability <±0.05% F.S./year

• Extremely low pressure and temperature hysteresis

• Built-in temperature sensor

• Various of isolated diaphragms to meet a wide range of anti-corrosion requirements

• Rugged construction with little effect of repackaging stress

Electrical Performance

• Power supply: 2.5-12VDC

• Electrical connection: 110mm silicone rubber soft wire/Kovar Pins

• Common mode voltage output: 50% of input (typical)

• Bridge resistance: 6kΩ±0.5kΩ

• Response time (10%-90% ): <2ms

• Insulation resistance: >100MΩ@500VDC

• Insulation strength: <5mA/500V AC

High stability piezoresistive sensor die

Isolated construction, applicable to measuring various fluid

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...

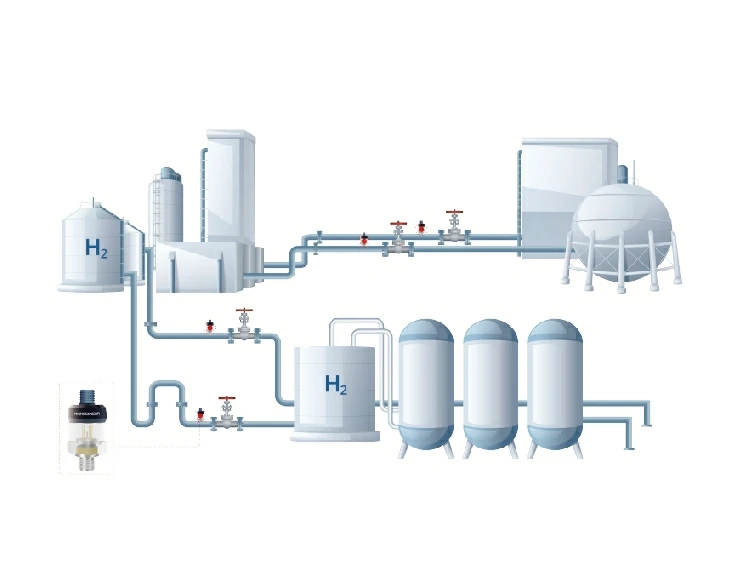

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...

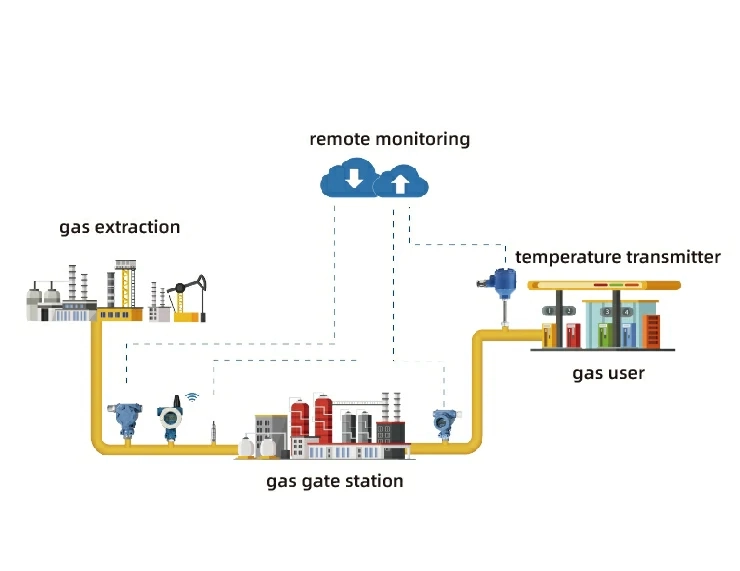

Natural gas undergoes a long process of transportation pipeline transmission, filtration, odorization, and pressure regulation from extraction to end-user consumption. In this process, monitoring the pressure and temperature within the pipeline is critical to ensuring the proper operation of the system.

more info...

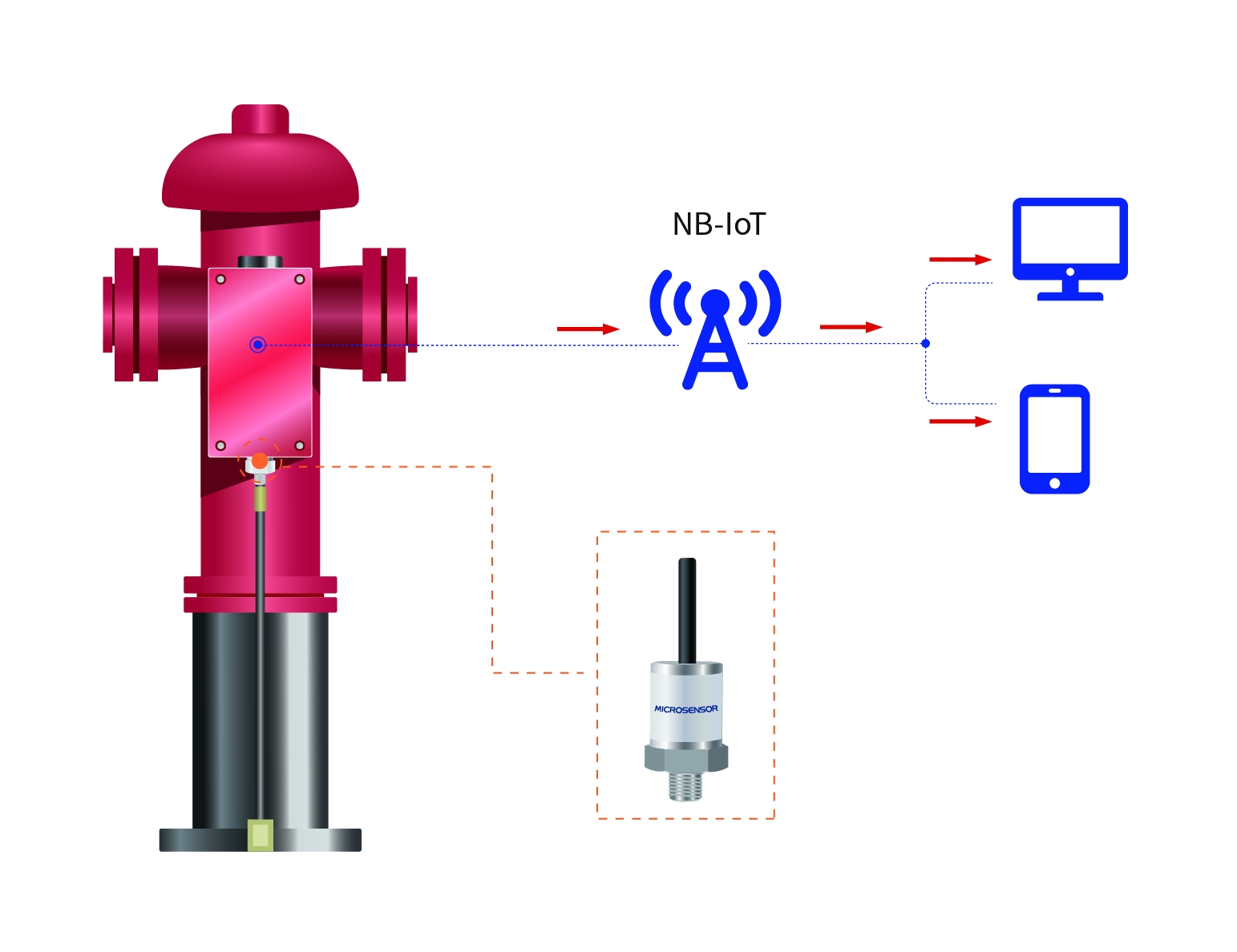

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...