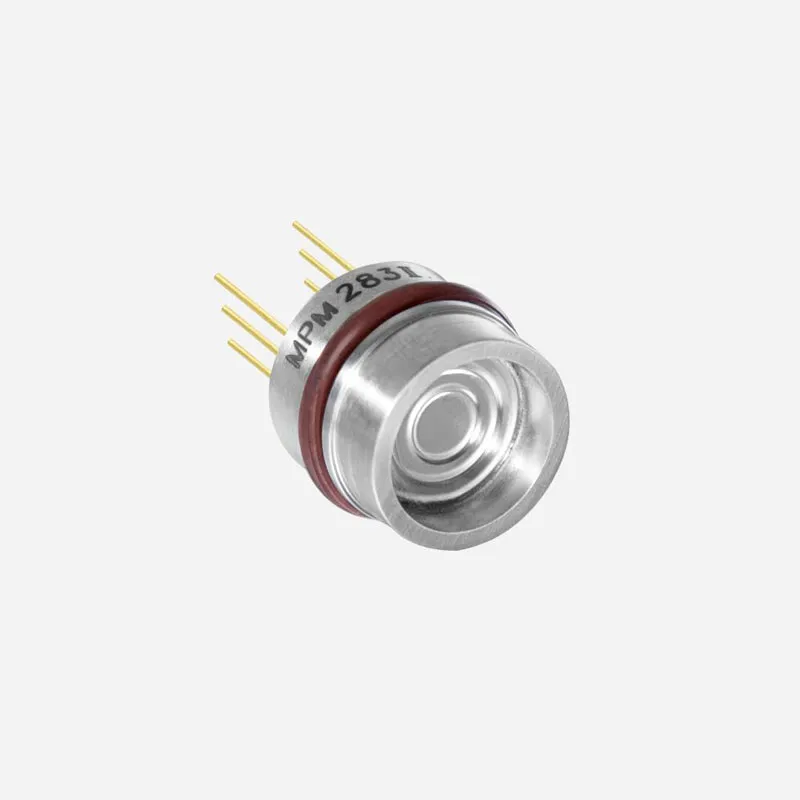

Oil-filled Pressure Sensor

Φ15×10.5mm

0bar~1bar...35bar

0~70℃ Compensated Temp.

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM283I

Used For

Industrial Process Control, Liquid Pressure System and Switch, Cooling Equipment and Air Conditioner, Aviation and Navigation Inspection

Leave a MessageThe measurement range of the MPM283I high pressure range pressure sensor is from 0 bar to 1000 bar. -10℃ ~80℃ temperature compensation range can be used in various applications. Small size saves space. Threaded connections of the high pressure sensor are easy to install. The isolation structure can measure various fluid media. Various pressure sensors of small size pressure sensors, anti-corrosive pressure sensors, and differential pressure sensors are available.

Feature

• Φ12.6mm OEM pressure sensor

• Stainless steel 316L or Hastelloy C is available

• Convenient threaded connection

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Electrical connection: Kovar or Silicon rubber flexible wires

• O-ring: FKM

• Net weight: ~8g

Image:

The measurement range of the MPM283I high pressure range pressure sensor is from 0 bar to 1000 bar. -10℃ ~80℃ temperature compensation range can be used in various applications. Small size saves space. Threaded connections of the high pressure sensor are easy to install. The isolation structure can measure various fluid media. Various pressure sensors of small size pressure sensors, anti-corrosive pressure sensors, and differential pressure sensors are available.

Feature

• Φ12.6mm OEM pressure sensor

• Stainless steel 316L or Hastelloy C is available

• Convenient threaded connection

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Electrical connection: Kovar or Silicon rubber flexible wires

• O-ring: FKM

• Net weight: ~8g

Range: -1bar…0bar~0.35bar…35bar

Output signal: Digital I²C (pressure, temperature)

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

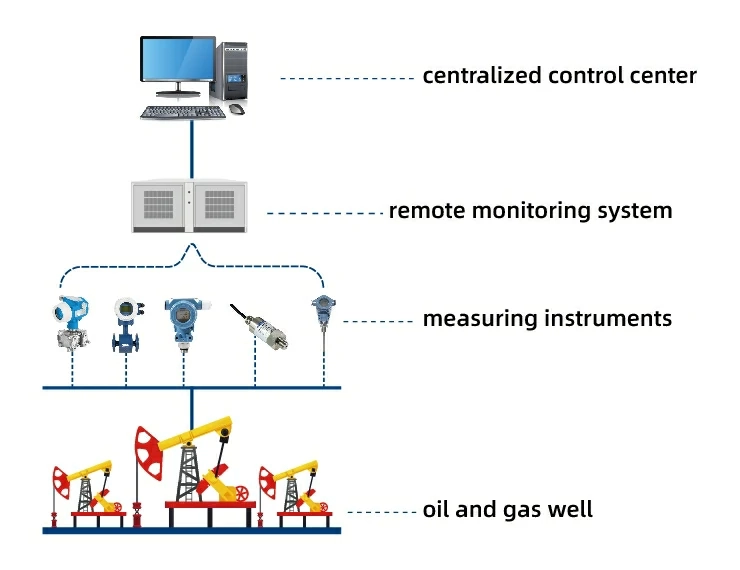

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...

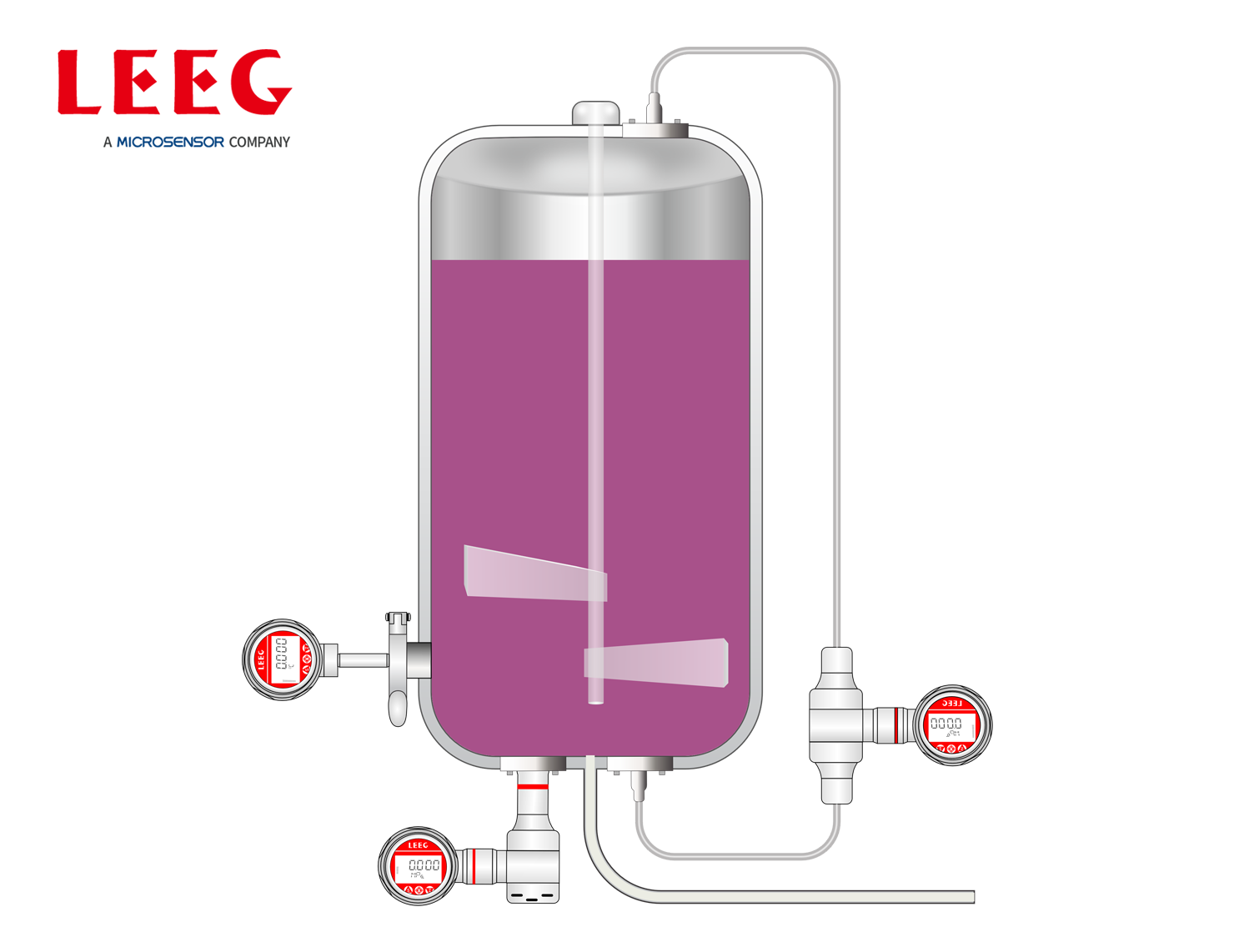

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...