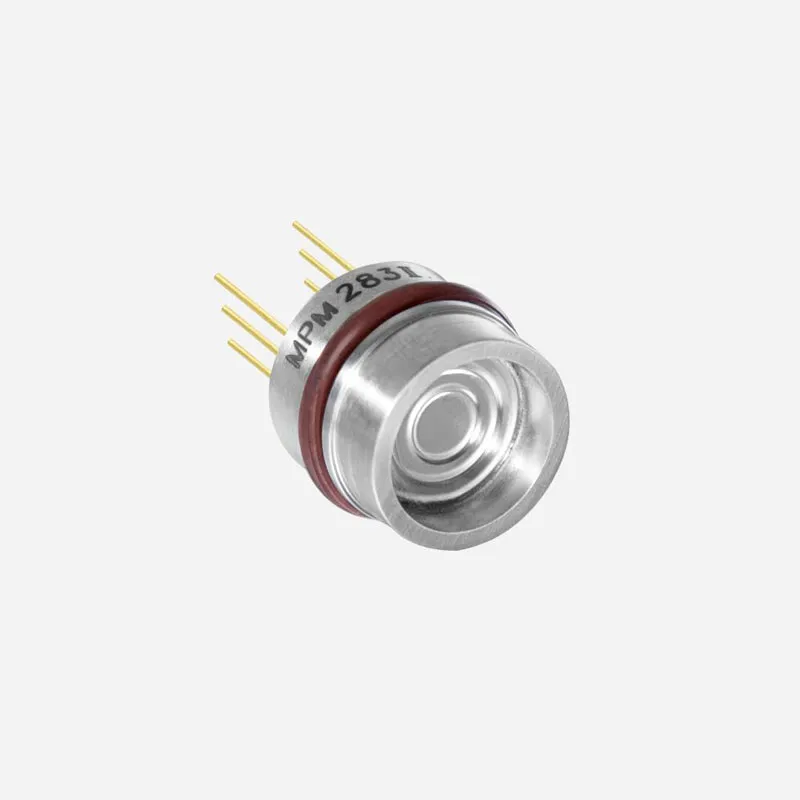

Pressure and Temperature Sensor

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM283II

Used For

Gas & Liquid Pressure Measurement, Pressure Inspection Meter, Pressure Calibrator

Leave a MessageMPM283II high-pressure sensor for tank level is made of a diffused pressure sensing die and stainless steel 316L housing. With a corrugated stainless steel 316L diaphragm, the measured pressure is transmitted to the sensing die through it and internally filled silicon oil. By doing linear correction and temperature compensation, the stable performance of the pressure transducer is guaranteed. With NBR or EPDM O-ring, it is easy for users to install and applicable for different temperature application. The pressure range is 0bar ~ 2.0bar…1000bar and the dimesion of the small pressure sensor is Φ12.6×10.5 mm.

Electrical Performance

• Power supply: ≤2.0mA DC

• Input impedance: 2kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulated resistor: 100MΩ@100V DC

• Overpressure: 2 times FS or 1100bar (min. value is valid)

Image:

MPM283II high-pressure sensor for tank level is made of a diffused pressure sensing die and stainless steel 316L housing. With a corrugated stainless steel 316L diaphragm, the measured pressure is transmitted to the sensing die through it and internally filled silicon oil. By doing linear correction and temperature compensation, the stable performance of the pressure transducer is guaranteed. With NBR or EPDM O-ring, it is easy for users to install and applicable for different temperature application. The pressure range is 0bar ~ 2.0bar…1000bar and the dimesion of the small pressure sensor is Φ12.6×10.5 mm.

Electrical Performance

• Power supply: ≤2.0mA DC

• Input impedance: 2kΩ~8kΩ

• Output impedance: 3.5kΩ~6kΩ

• Response (10%~90%): <1ms

• Insulated resistor: 100MΩ@100V DC

• Overpressure: 2 times FS or 1100bar (min. value is valid)

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

Range: -1bar…0bar~0.35bar…35bar

Output signal: Digital I²C (pressure, temperature)

Range: -1bar…-0.35bar ~ 0bar ~0.35bar…700bar

No need for re-calibration for users, high precision

Customizable dimensions

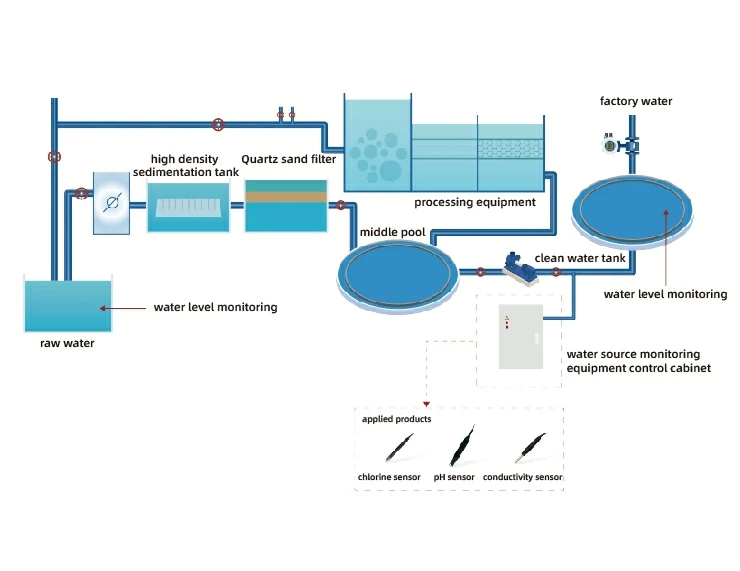

Pressure, flow, and level measuring instruments are deployed in water tanks, pipelines, and water inlets/outlets. This helps to manage the macro-control of production data in the water plant. Measuring instruments ensure smooth operation and normal production.

more info...

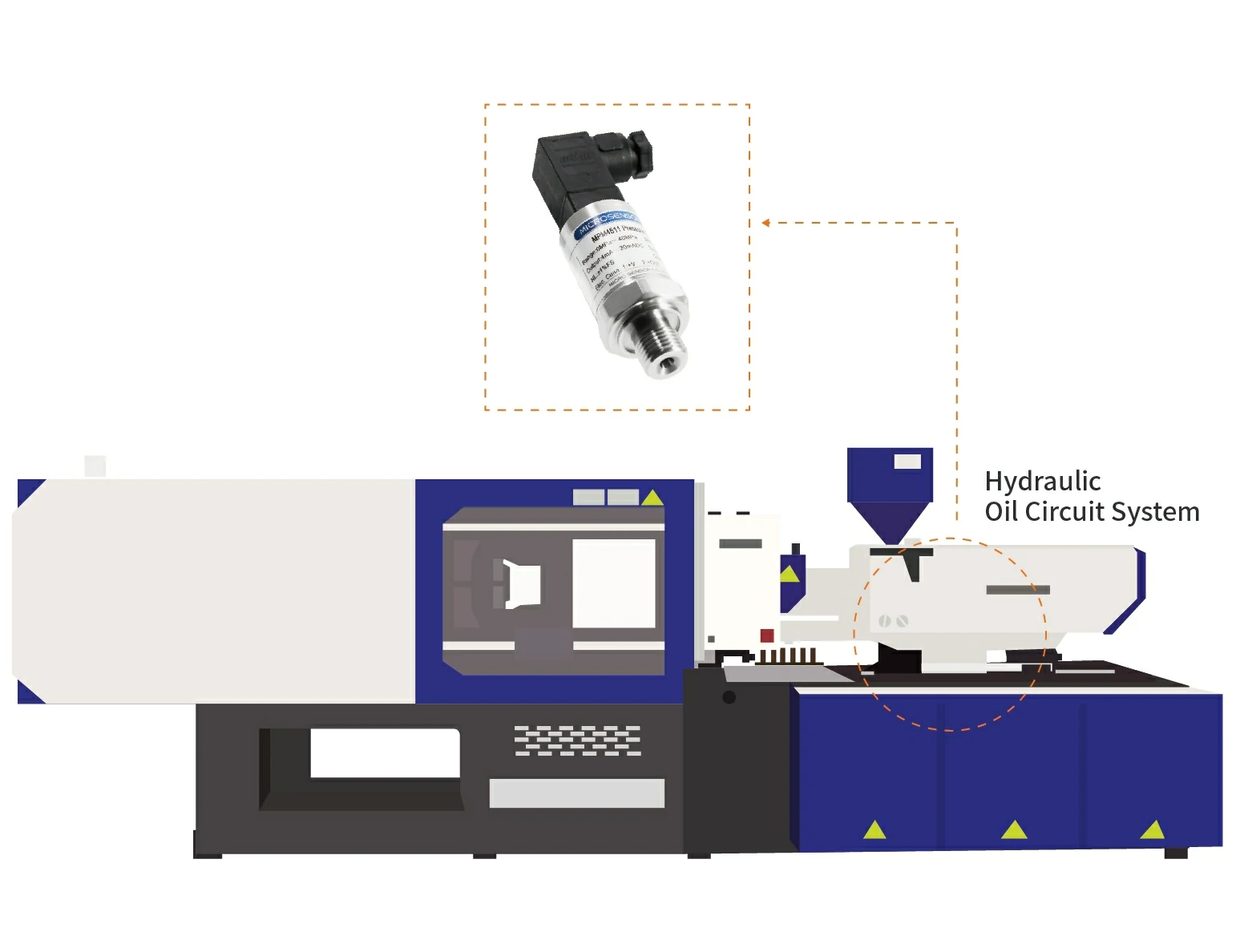

With the pressure transmitter, the pressure value of the hydraulic oil circuit system of the injection molding machine is monitored in real time, so as to provide reliable closed-loop control feedback signals for the stable operation of the hydraulic system.

more info...

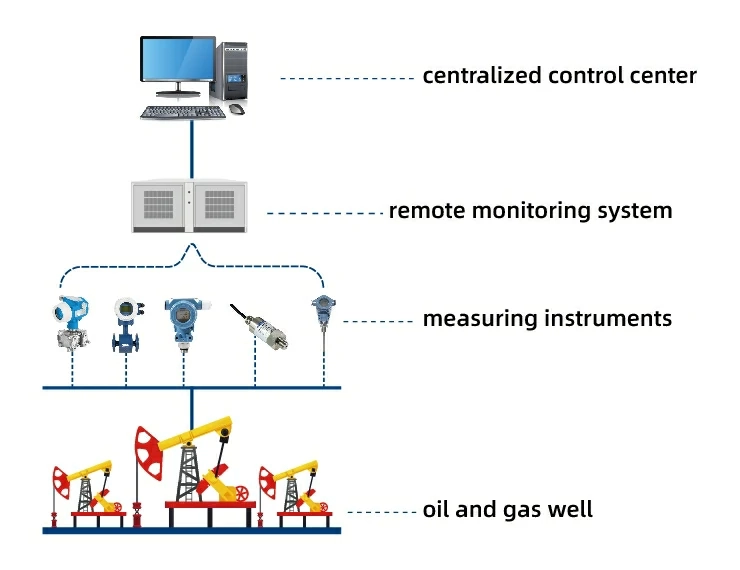

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...