Differential Pressure Transmitter for Oxygen Pressure Measurement

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM280Au

Used For

Hydrogen Pressure Measurement in hydropen production, transportation and storage

Leave a MessageMPM280Au Hydrogen Pressure Sensor is specially developed for hydrogen measurement applications. High precision and high stability chips are selected for reliable performance. The isolated structure and gold-plated corrugated diaphragm effectively prevent the occurrence of "hydrogen embrittlement" and "hydrogen permeation" in hydrogen measurement applications, which not only ensures on-site safety but also improves the service life of the sensor.

Features

• Pressure range: -1bar…0bar ~ 0.35bar…200bar

• Isolated structure, specialized for hydrogen pressure measurement

• Φ19mm OEM type

Basic Condition

• Media temperature: (35±1)℃

• Environment temperature: (35±1)℃

• Local air pressure: (0.86 ~ 1.06)bar

• Power supply: (1.5±0.0015)mADC

Image:

MPM280Au Hydrogen Pressure Sensor is specially developed for hydrogen measurement applications. High precision and high stability chips are selected for reliable performance. The isolated structure and gold-plated corrugated diaphragm effectively prevent the occurrence of "hydrogen embrittlement" and "hydrogen permeation" in hydrogen measurement applications, which not only ensures on-site safety but also improves the service life of the sensor.

Features

• Pressure range: -1bar…0bar ~ 0.35bar…200bar

• Isolated structure, specialized for hydrogen pressure measurement

• Φ19mm OEM type

Basic Condition

• Media temperature: (35±1)℃

• Environment temperature: (35±1)℃

• Local air pressure: (0.86 ~ 1.06)bar

• Power supply: (1.5±0.0015)mADC

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

Hydrogen Service Gold Plated Diaphragm

Range: 0mbar ~ 250mbar...70bar

Output Signal: 4~20mA 0/1~5/10V DC 0.5~4.5V DC 0.5~2.5V DC

Widely used in the medical and pharmaceutical industry for oxygen measurement

All-welded design

Fully digital temperature compensation calibration

Adapted to breathable membranes

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

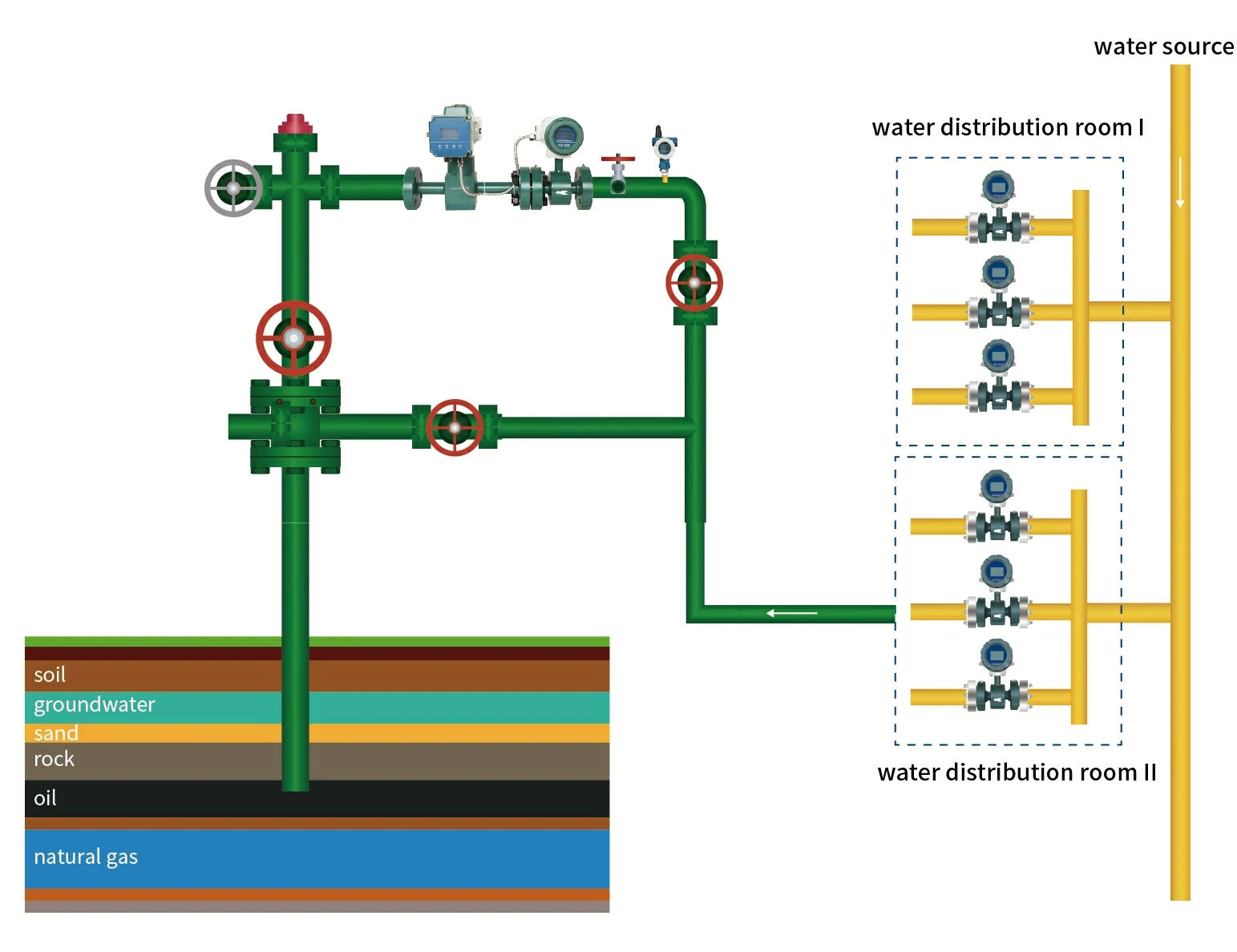

Install instruments like electromagnetic flowmeters, temperature/pressure transmitters, flow controllers in the pressure pumps, water injection pipelines, and water injection wells to monitor the water injection volume, pressure, and level changes in real time so that the pressure and volume of the well-injected water can be controlled.

more info...

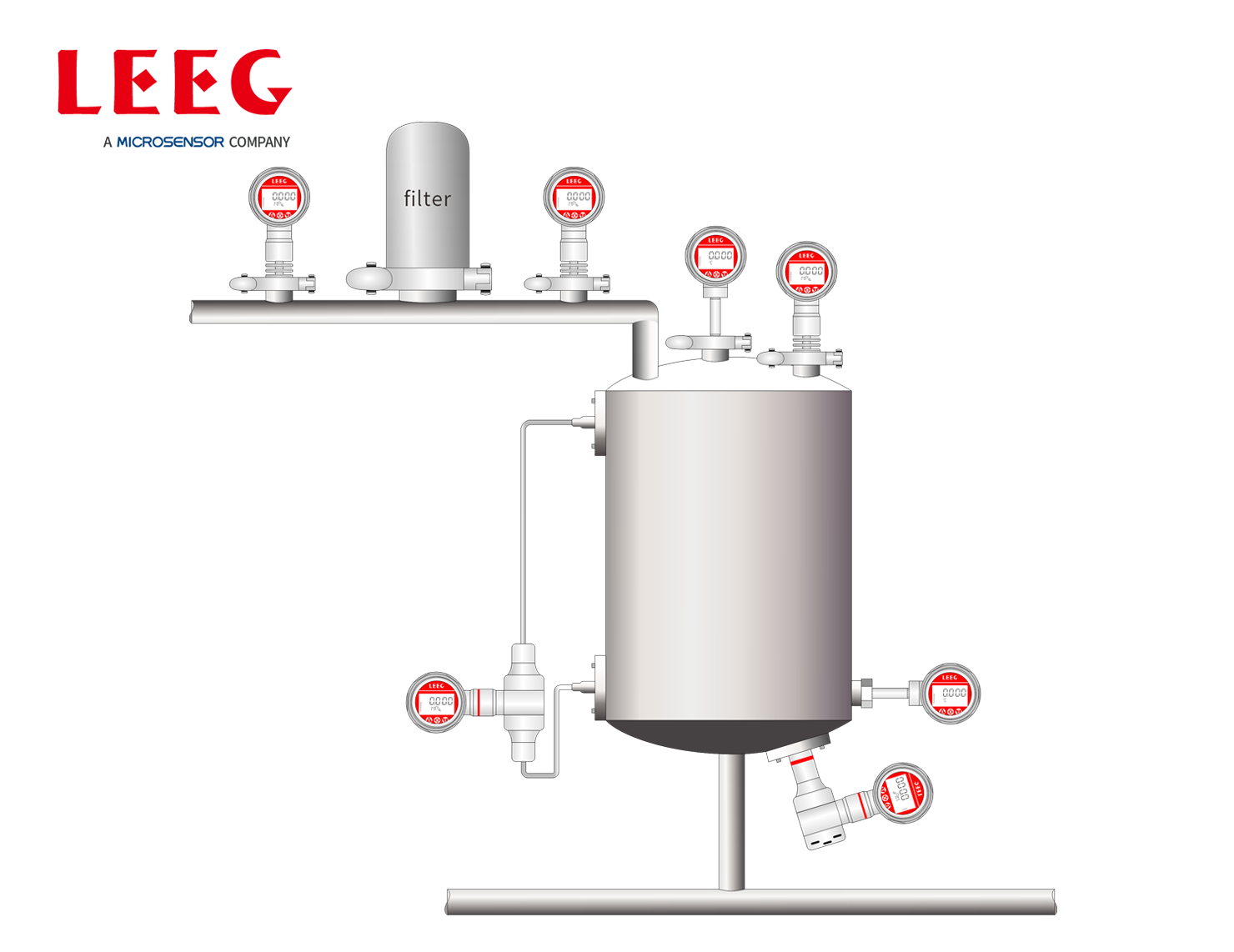

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...

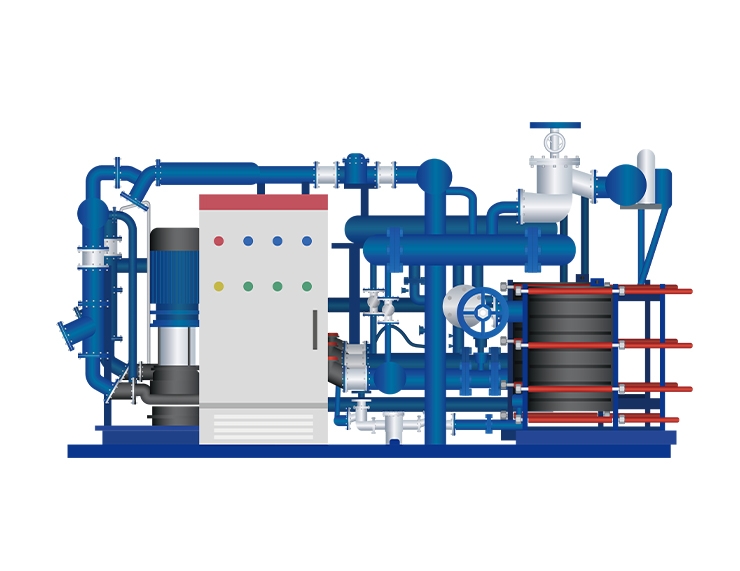

Pressure transmitters, temperature tranmitters and electromagnetic flowmeters are installed in the marine water circulation cooling system to ensure the heat exchange efficiency of the central cooler. By optimizing seawater flow control, energy saving effects are maximized and stable operation of the cooling system is ensured.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...