Differential Pressure Transmitter for Oxygen Pressure Measurement

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

M20FL

Used For

Pharmaceutical Industry, Aerospace Industry, Chemical Industry, Metallurgy, Energy

Leave a MessageM20FL pressure transmitter is a specialized oxygen measurement transmitter developed by our company, filled with internally flushed Fluorinated® oil, which features high accuracy, stability, and safety level. Additionally, it is designed with precision and high integration of electrical structure, uses fully digital temperature compensation and calibration, is made of carefully selected materials with good electromagnetic compatibility design, and has excellent reliability and cost-effectiveness.

M20FL pressure transmitter meets the cleaning requirements of ISO 15001/ASMT G-93 and other standards. It is widely used in the medical and pharmaceutical industries, providing a professional solution to the measurement of gas pressure in medical oxygen production equipment and oxygen tanks.

Specifications

• Pressure Type: Gauge, Absolute, Positive/Negative

• Pressure Range: 0kPa ~ 25kPa to 0MPa ~ 25MPa

• Electrical Connection:

Angular Connector DIN 175301-803A

Circular Aviation Plug M12×1(4pin) IEC 61076-2-101

Cable Φ5.0mm 5×0.12mm² Polyurethane

Image:

M20FL pressure transmitter is a specialized oxygen measurement transmitter developed by our company, filled with internally flushed Fluorinated® oil, which features high accuracy, stability, and safety level. Additionally, it is designed with precision and high integration of electrical structure, uses fully digital temperature compensation and calibration, is made of carefully selected materials with good electromagnetic compatibility design, and has excellent reliability and cost-effectiveness.

M20FL pressure transmitter meets the cleaning requirements of ISO 15001/ASMT G-93 and other standards. It is widely used in the medical and pharmaceutical industries, providing a professional solution to the measurement of gas pressure in medical oxygen production equipment and oxygen tanks.

Specifications

• Pressure Type: Gauge, Absolute, Positive/Negative

• Pressure Range: 0kPa ~ 25kPa to 0MPa ~ 25MPa

• Electrical Connection:

Angular Connector DIN 175301-803A

Circular Aviation Plug M12×1(4pin) IEC 61076-2-101

Cable Φ5.0mm 5×0.12mm² Polyurethane

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

Hydrogen Service Gold Plated Diaphragm

Range: 0mbar ~ 250mbar...70bar

Output Signal: 4~20mA 0/1~5/10V DC 0.5~4.5V DC 0.5~2.5V DC

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

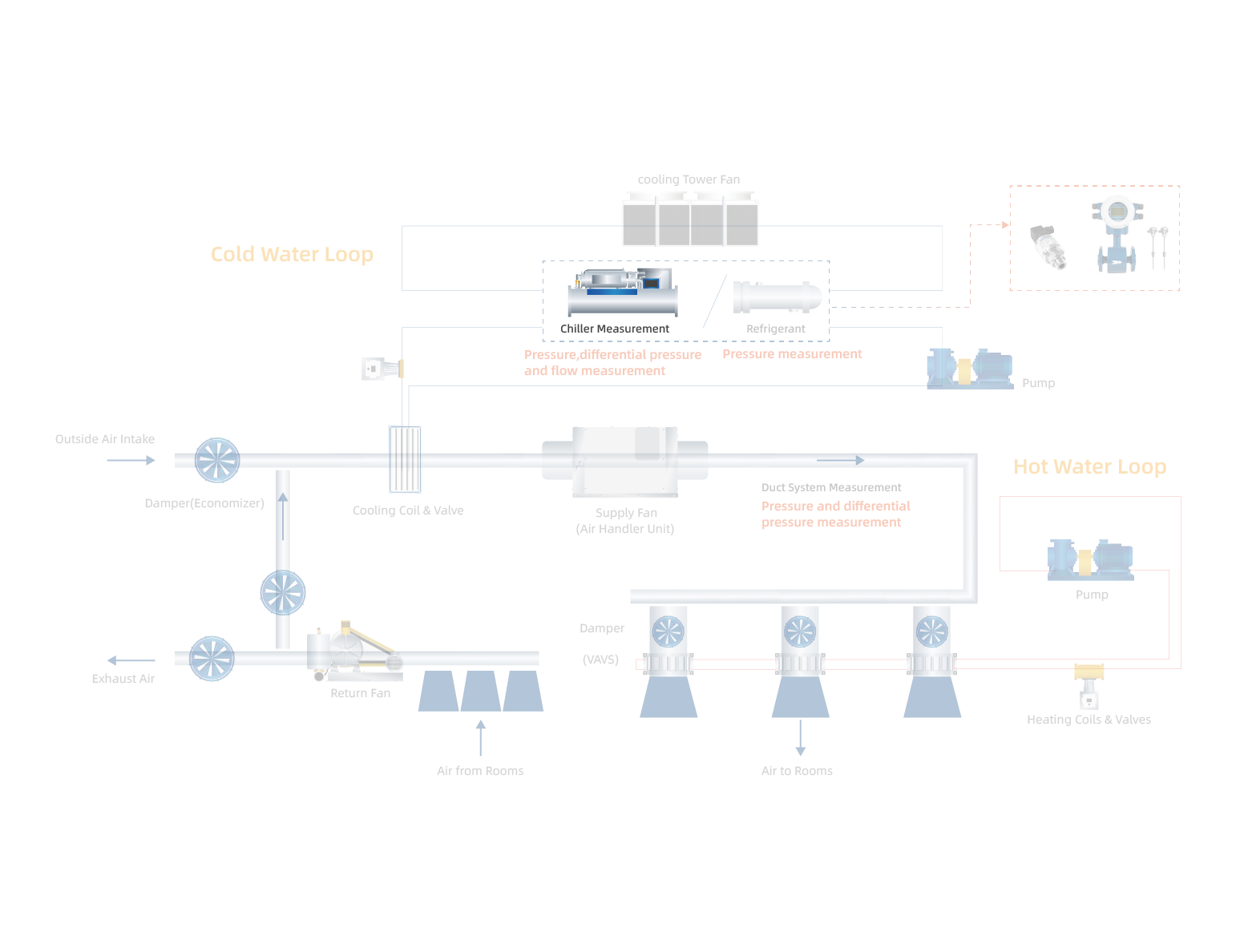

In the HVAC chiller systems, measuring heat and pressure is vital for optimal performance. Pressure transmitters ensure the refrigerant operates within safe limits, while flow meters and temperature sensors calculate heat exchange efficiency. Accurate measurements enhance system reliability, and efficiency, and prevent potential failures.

more info...

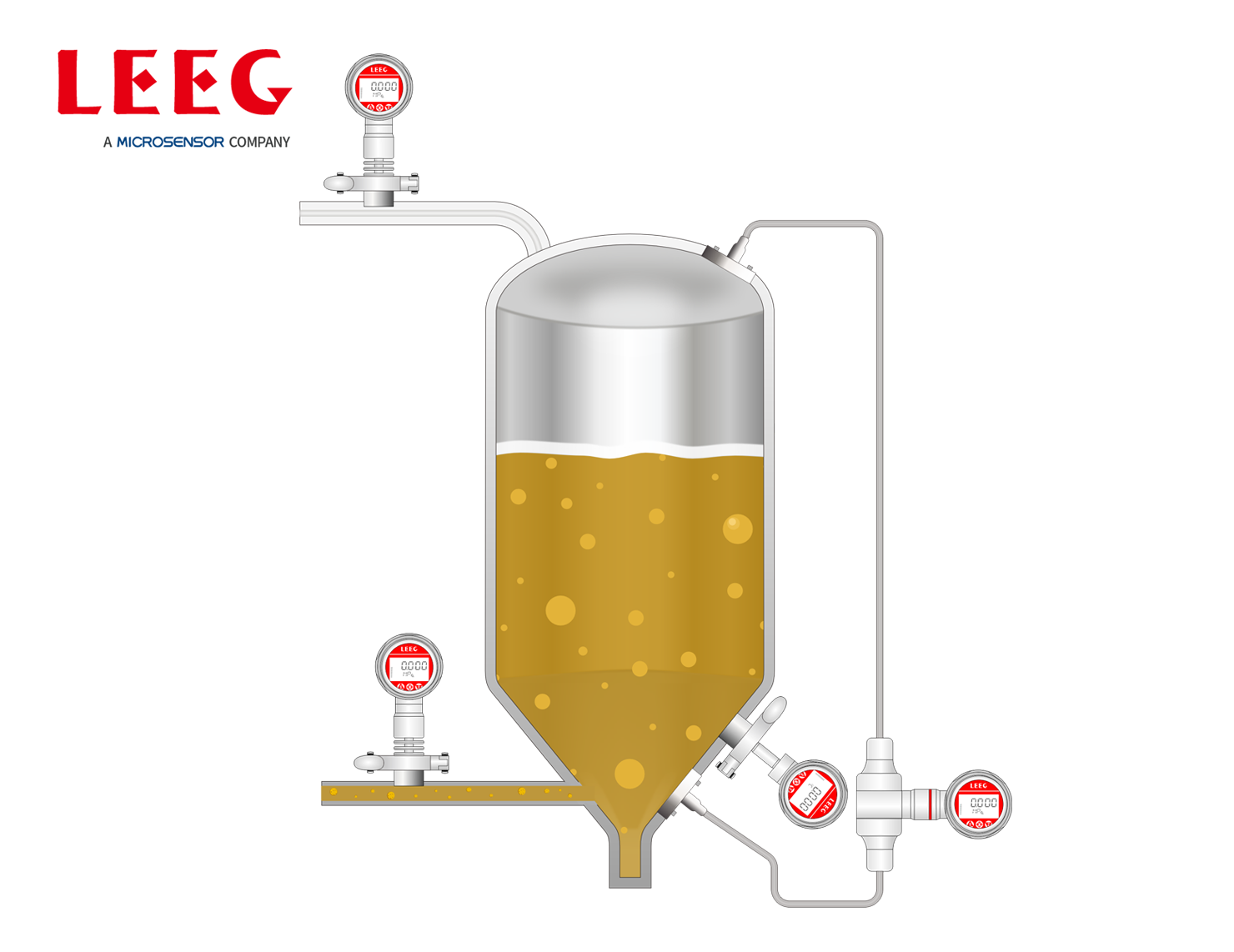

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...

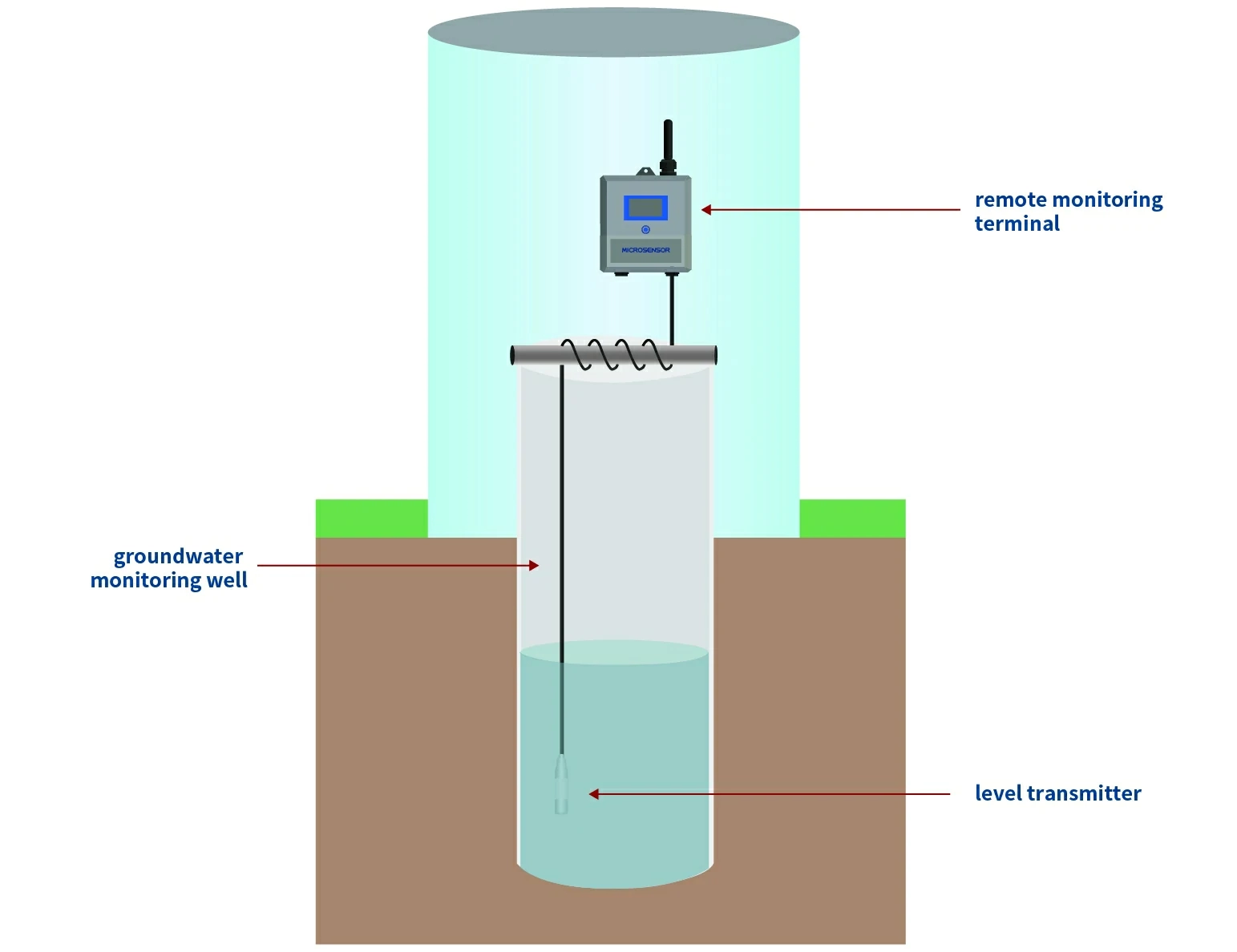

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...