Differential Pressure Transmitter for Oxygen Pressure Measurement

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

MPM480GH

Used For

Hydrogen Production System, PEM Fuel Cell, Hydrogen Fuel Cell Test Station, Hydrogen Fuel Cell Vehicle Test System

Leave a MessageMPM480GH pressure transmitter is specially used for hydrogen measurement. It helps users safely and reliably carry out hydrogen production operations. The accuracy of this product is as high as ≤±0.25%FS. The adoption of all-welded structure has strong sealing. It adopts the gold-plated diaphragm scheme, which reduces the penetration of hydrogen gas and prevents the occurrence of hydrogen embrittlement. Explosion-proof circuits support use in hazardous locations.

MPM480GH Pressure Transmitter for Hydrogen Measurement is suitable for electrolyzer pressure and liquid level measurement, gas-liquid hydrogen storage tank pressure and liquid level measurement, hydrogen transportation pipeline pressure measurement and other scenarios, providing professional monitoring equipment for the precise operation of the hydrogen energy industry.

Feature

• For industrial gas measurement

• Development and verification under a hydrogen environment

• Gold-plated sensor diaphragm

• Various output signals are optional

Image:

MPM480GH pressure transmitter is specially used for hydrogen measurement. It helps users safely and reliably carry out hydrogen production operations. The accuracy of this product is as high as ≤±0.25%FS. The adoption of all-welded structure has strong sealing. It adopts the gold-plated diaphragm scheme, which reduces the penetration of hydrogen gas and prevents the occurrence of hydrogen embrittlement. Explosion-proof circuits support use in hazardous locations.

MPM480GH Pressure Transmitter for Hydrogen Measurement is suitable for electrolyzer pressure and liquid level measurement, gas-liquid hydrogen storage tank pressure and liquid level measurement, hydrogen transportation pipeline pressure measurement and other scenarios, providing professional monitoring equipment for the precise operation of the hydrogen energy industry.

Feature

• For industrial gas measurement

• Development and verification under a hydrogen environment

• Gold-plated sensor diaphragm

• Various output signals are optional

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

Oxygen DP Measurement

Widely used in the medical and pharmaceutical industry for oxygen measurement

All-welded design

Fully digital temperature compensation calibration

Adapted to breathable membranes

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

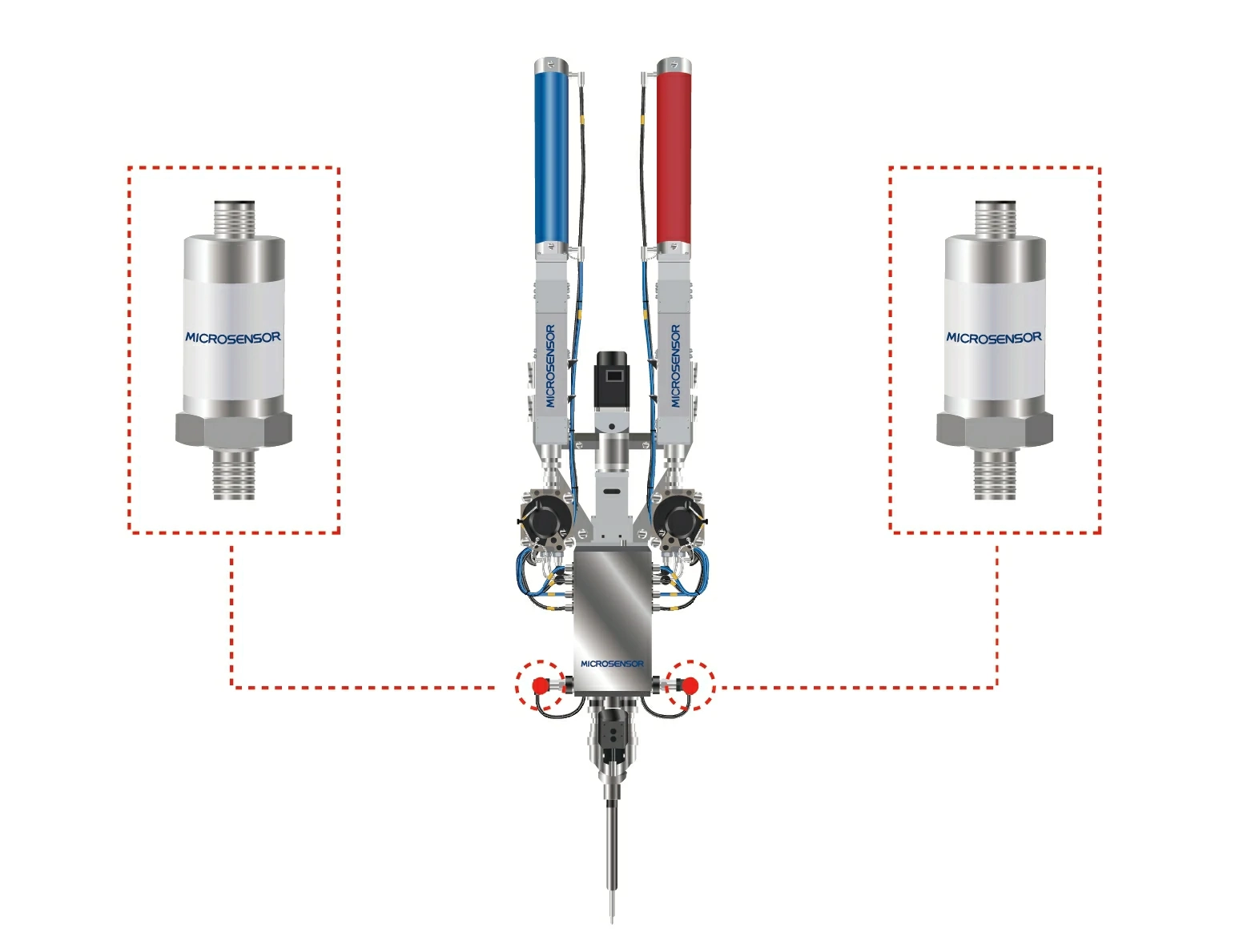

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

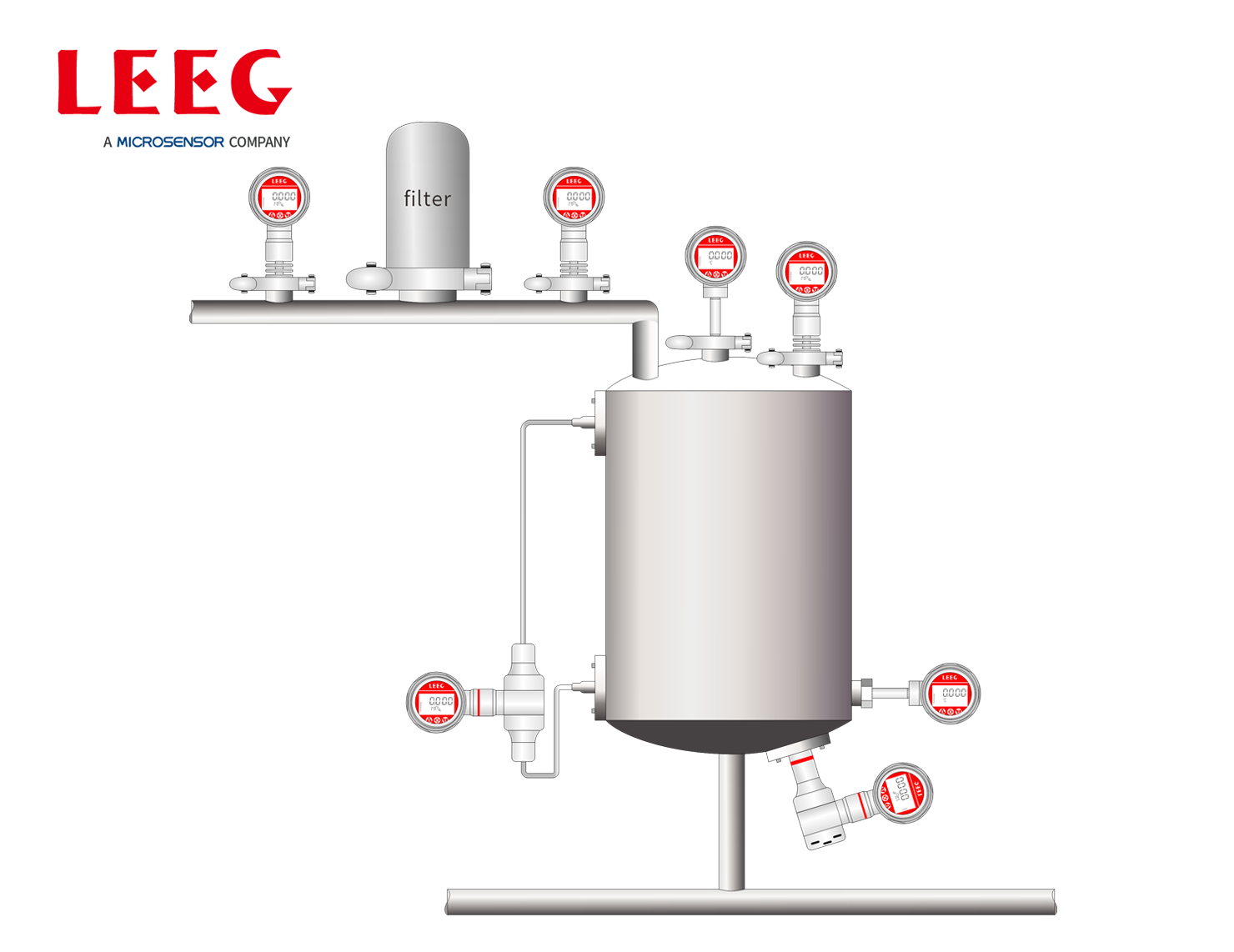

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...

To ensure the fuel supply of the main engine, the separated heavy oil is first pumped to the settling tank, where the oil is heated and separated in the heating coil, and then purified by the oil separator before entering the daily tank through high-level overflow. The daily tank is directly connected to the main engine, boiler or other equipment, and the oil can be heated and used at any time.

more info...

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...