ATEX Pressure Transmitter

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM4901FL

Used For

Medical and Pharmaceutical Industries, Oxygen Storage Tanks

Leave a MessageMDM4901FL differential pressure transmitter is designed for oxygen pressure measurement. MDM4901FL gas pressure transducer is filled with fluorine oil inside. After being cleaned through a special process, the product meets the conditions of oxygen measurement and oil-free body. High accuracy and high stability cryogenic pressure transducer for oxygen measurement solves the problem of measuring gas differential pressure in industrial oxygen vertical/horizontal storage tanks.

Feature

• Special for oxygen pressure measurement

• Pressure range from 350 mbar to 35 bar

• Easy to operate and verify

• CE certification and RoHS certification

Image:

MDM4901FL differential pressure transmitter is designed for oxygen pressure measurement. MDM4901FL gas pressure transducer is filled with fluorine oil inside. After being cleaned through a special process, the product meets the conditions of oxygen measurement and oil-free body. High accuracy and high stability cryogenic pressure transducer for oxygen measurement solves the problem of measuring gas differential pressure in industrial oxygen vertical/horizontal storage tanks.

Feature

• Special for oxygen pressure measurement

• Pressure range from 350 mbar to 35 bar

• Easy to operate and verify

• CE certification and RoHS certification

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Hydrogen Service Gold Plated Diaphragm

Range: 0mbar ~ 250mbar...70bar

Output Signal: 4~20mA 0/1~5/10V DC 0.5~4.5V DC 0.5~2.5V DC

Widely used in the medical and pharmaceutical industry for oxygen measurement

All-welded design

Fully digital temperature compensation calibration

Adapted to breathable membranes

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

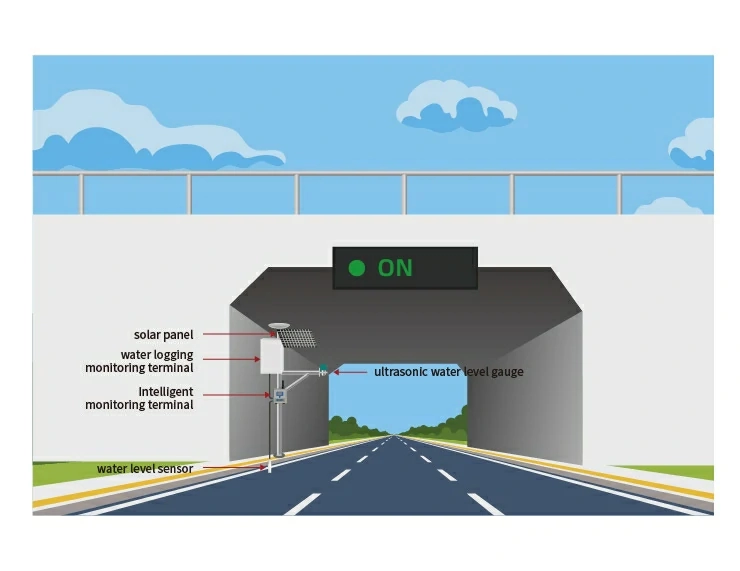

Real-time monitoring the low-ling areas, underpasses and bridge culverts. The current level and alarming messages are automatically displayed on the screen, such as “Passage”, “Allowing”, and “No entering”. The alarm will be triggered when the level is too high, aiming to ensure the personnel's safety.

more info...

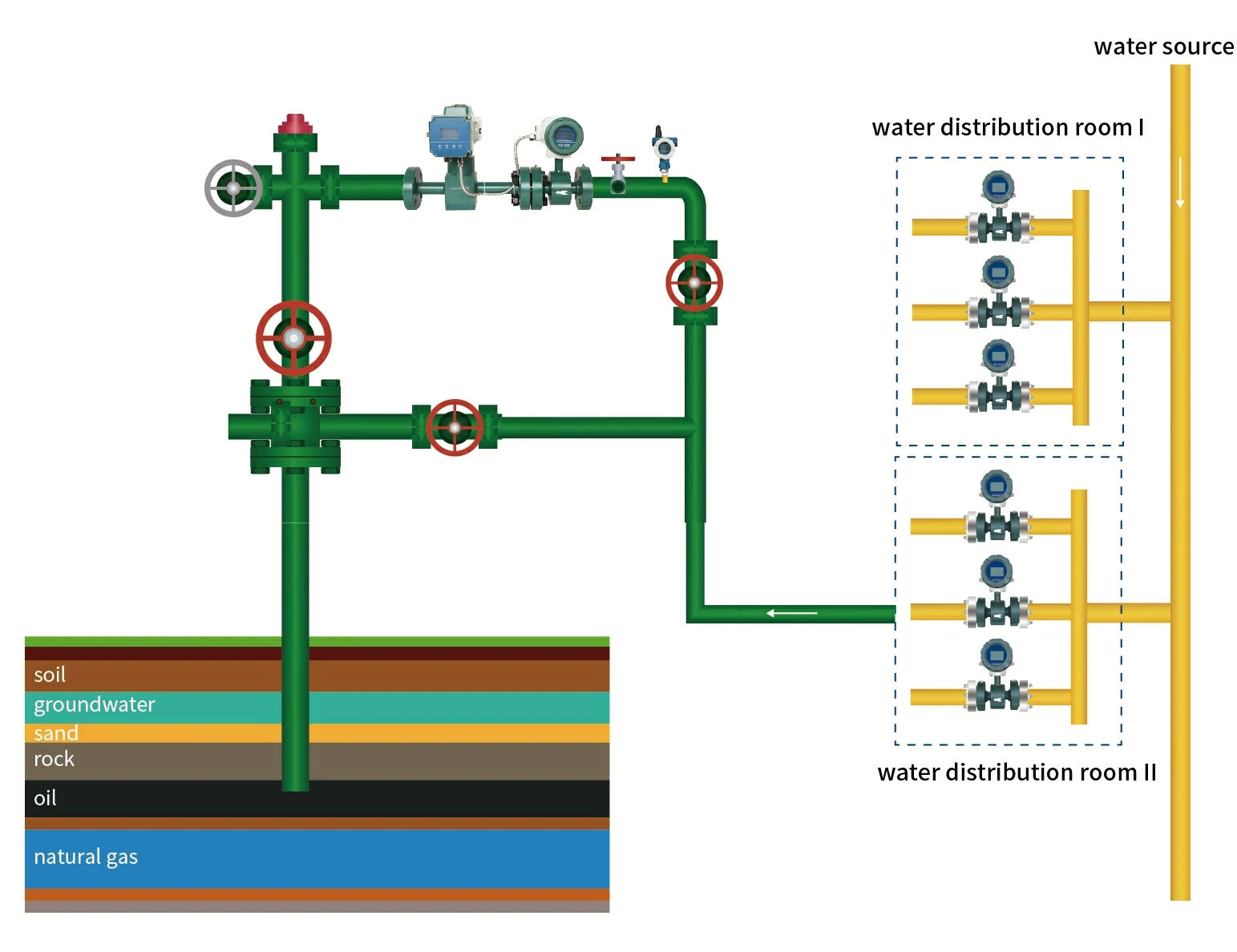

Install instruments like electromagnetic flowmeters, temperature/pressure transmitters, flow controllers in the pressure pumps, water injection pipelines, and water injection wells to monitor the water injection volume, pressure, and level changes in real time so that the pressure and volume of the well-injected water can be controlled.

more info...

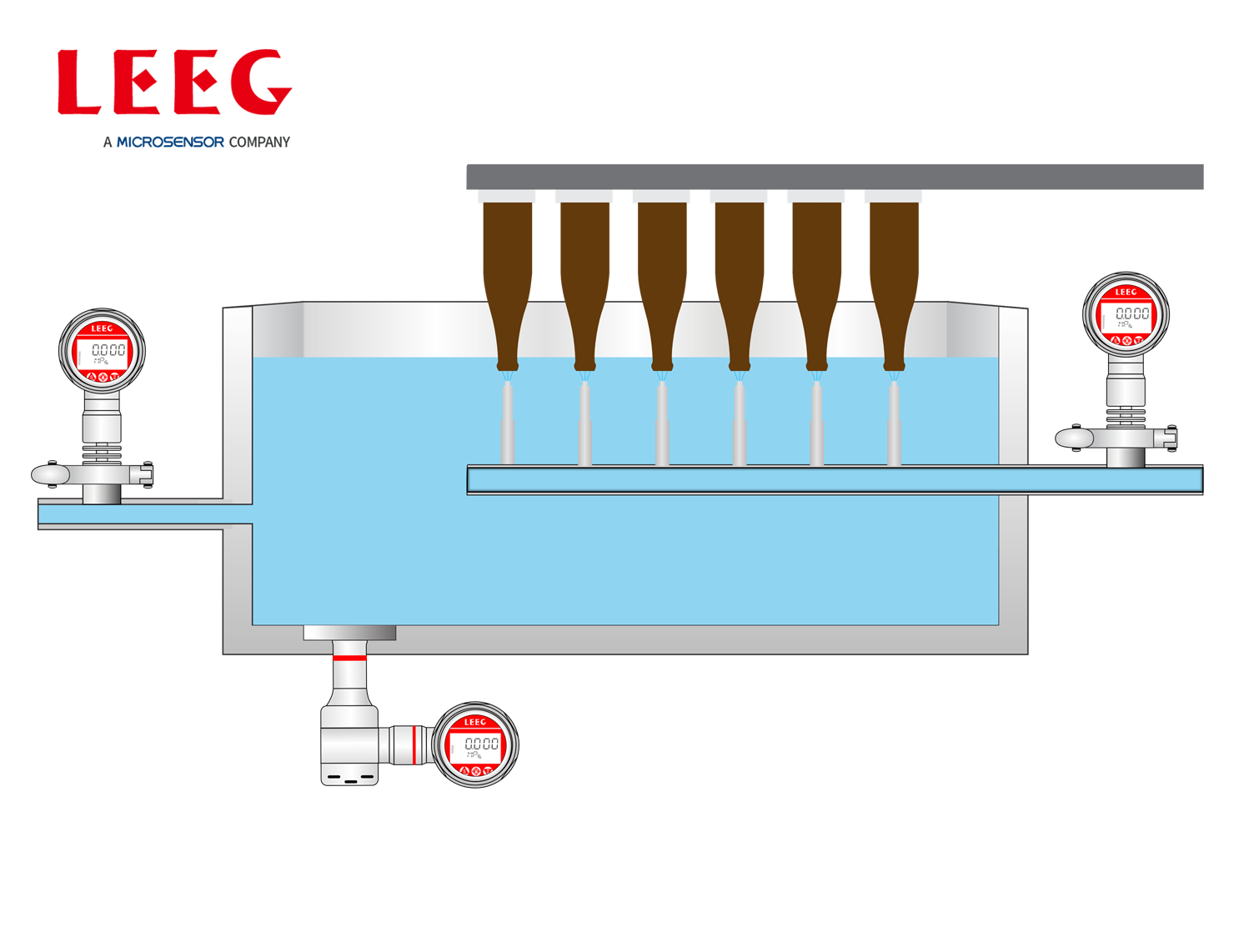

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...

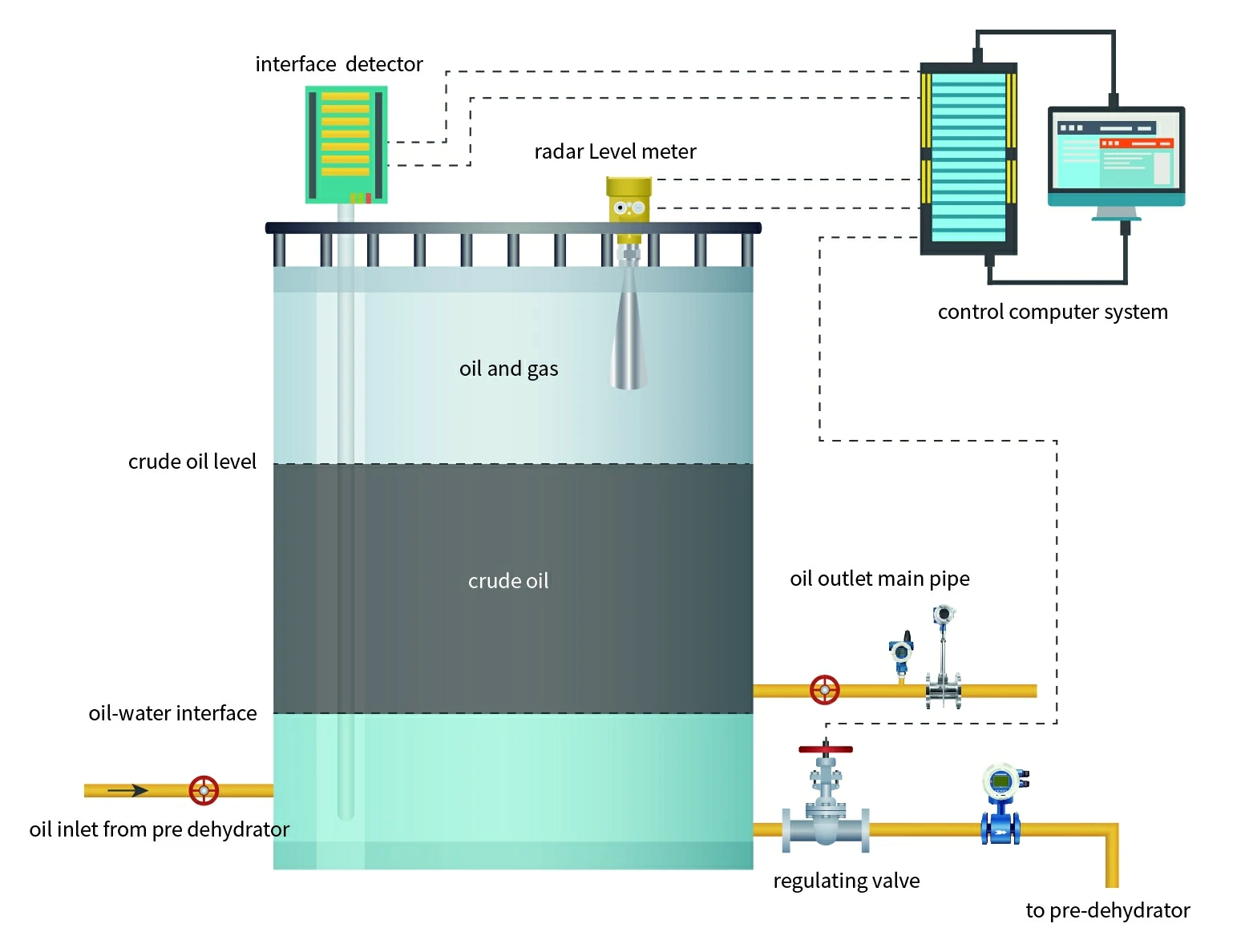

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...