Overview of the Shipbuilding Industry

As a means of transportation, ships can sail or be anchored in waters for transportation or operations. It has a huge control system, and each system has different requirements for pressure and level measurement. Its control system includes fuel monitoring system, water circulation cooling system, valve remote control system, ballast water system, and temperature control system. Whether the pressure transmitter is sturdy and durable and whether it can perform accurate measurements is very important for each system. Pressure sensors provide the necessary data and output for energy consumption and positioning. In addition, pressure measurement in equipment status detection and early warning also provides basic data support for the reliability and failure rate of ship systems.

|  |

(MicroSensor Customer Application Site)

Measuring Solution for Shipbuilding

• Fuel Monitoring System

In the shipbuilding industry, shipping companies and shipyards attach great importance to ship carbon emission verification and management. During the voyage, it is necessary to monitor the fuel and formulate protocols based on operating data to achieve energy conservation and emission reduction while ensuring normal production and operations.

Challenges: Abnormal fuel consumption monitoring, carbon emission verification

Solutions: Use the data collected by sensors to view location and real-time fuel consumption, query historical trajectories, calculate voyage mileage and total fuel consumption, and analyze the rationality of ship operation.

Products: Pressure Transmitter, Level Transmitter, Mass Flowmeter

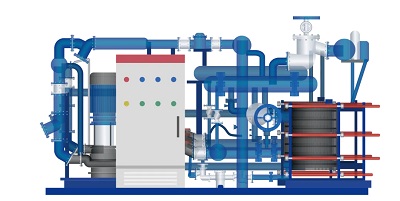

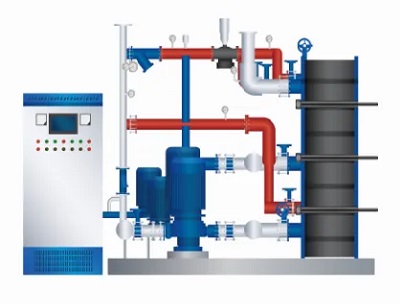

• Water Circulation Cooling System

During navigation, the ship's main engine and auxiliary engine systems will generate too much heat after operating. At this time, the equipment will stop operating because the temperature is too high, and seawater or fresh water needs to be used for cooling.

Challenges: High energy consumption, unstable control temperature

Applications: Open-loop seawater cooling system, closed-loop freshwater cooling system, central cooling system.

Solutions: In order to keep the cooling water temperature stable and allow the central cooler to automatically adjust under different heat loads, it is necessary to monitor the flow of seawater and fresh water to ensure heat exchange efficiency and achieve maximum energy saving and optimized seawater utilization.

Products: Pressure Transmitter, Temperature Transmitter, Electromagnetic Flowmeter

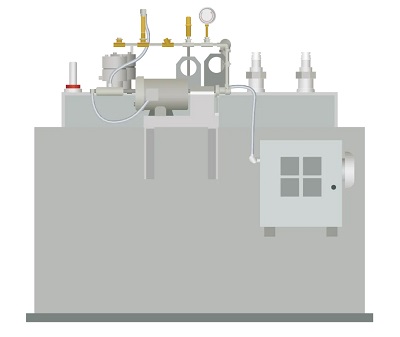

• Valve Remote Control System

In order to ensure that the main engine has enough fuel, the separated heavy oil is first pumped to the sedimentation tank, and then the separated oil is heated through the heating coil, purified by the oil separator, and continuously flows into the daily tank from a high position. The daily box is directly connected to the main engine, boiler or other equipment, and fuel can be obtained by heating at any time.

Challenges: Reliable level and temperature measurements

Applications: The daily tank for fuel oil (heavy oil, black oil), fuel oil settling tank, diesel daily tank, fuel oil storage tank, and lubricating oil storage tank.

Solutions: Using the valve remote control system, users can know the oil and gas reserves on the ship at any time, and then formulate a more accurate refueling plan to improve fuel utilization. It can also effectively prevent safety accidents caused by insufficient fuel during navigation.

Products: Level Transmitter, Temperature Transmitter

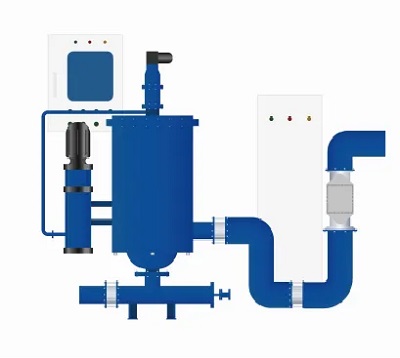

• Ballast Water System

The measurement results of ballast water in double bottom tanks, fore peak tank, aft peak tank, side tank, or deep tank are directly utilized for the calculation and control of ship attitude, including draft depth, longitudinal trim, and transverse heel.

Challenges: During onboard operations, these measurement points are essentially inaccessible, making reliability and stability crucial requirements for measurement equipment. Additionally, high demands are placed on level instruments due to factors such as impact pressure, gravel erosion, and slightly saline water.

Applications: Double bottom tanks, fore peak tank, aft peak tank, side tank, or deep tank.

Solutions: By using electromagnetic flowmeters, level transmitters, pressure sensors and other equipment to monitor water inflow, water tank level and pressure data, to achieve precise control of the ballast water system.

Products: Pressure Transmitter, Level Transmitter, Electromagnetic Flowmeter

• Temperature Control System

The working principle of the ship air conditioning and refrigeration system is similar to that of ordinary air conditioners, which use refrigerant to circulate between the condenser and evaporator to achieve cooling and dehumidification effects.

Challenges: In a marine environment, the salt in seawater will corrode many conventional materials, so corrosion-resistant materials, such as stainless steel and special plastics, are usually used when manufacturing various parts of the cooling system. Due to the large temperature changes, the measurement requirements for the temperature range are also very wide. In addition, due to the limited space of the vessel, the design and layout of the product must be compact and practical.

Applications: Marine electric heating system, marine refrigeration equipment

Solutions: Sensors and flowmeters made of corrosion-resistant materials that can withstand harsh environments are used to cope with harsh conditions such as large temperature differences and high amounts of salt. When these efficient and accurate measuring instruments are connected to the automation system, they can greatly reduce energy consumption and facilitate remote management.

Products: Pressure Transmitter, Temperature Transmitter, Electromagnetic Flowmeter

Recommended Products

• Pressure Transmitter

| • Explosion-proof certificate for shipbuilding and marine equipment industry • Range: -1bar...0bar~0.1bar...1000bar • Overpressure: 1.5×FS or 1100bar (min. value is valid) • Output: 4mA~20mA DC 0.5V~2.5V/4.5V DC/0/1V~5/10V DC • Accuracy: ±0.5%FS, ±0.1%FS • Power supply: 11V~28V DC, 3.3V/5V DC • Operating temperature: -30℃~80℃ • Connection method: Connector or cable |

• Level Transmitter

| • High stability, digital output, wide temperature compensation • Range: 3.5 …7~200m H₂O • Output: 4mA~20mA DC, RS485/HART protocol • Accuracy: ±0.075%FS, ±0.1%FS, ±0.25%FS • Power supply: 10V~28V DC (RS485), 12V~30V DC (HART) • Operating temperature: -10℃~70℃ • IP rating: IP68 |

• Temperature Transmitter

| • High accuracy, integrated/separated type • Range: -200°C~500°C • Graduated No: PT100 PT1000 • Accuracy: ±1.0%FS (-200℃...0℃~500℃), ±0.5%FS (-40℃...0℃~125℃), ±0.25%FS (-20℃...0 ℃~105℃) • Output: 4mA~20mA DC, RS485, 4mA~20mA DC+HART, 4mA~20mA DC+RS485 • Power Supply: 10V~30VDC |

• Smart Pressure Transmitter

| • High accuracy High stability • Range: 0.06bar~30bar • Output: 4mA~20mA DC+HART • Accuracy: ±0.05%, ±0.075 • Operating temperature: -40℃~85℃, -20°C~70°C (LCD) • IP rating: IP67 |

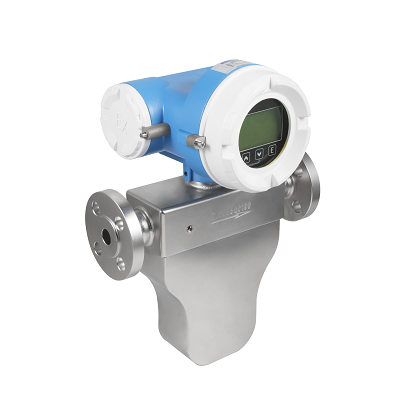

• Electromagnetic Flowmeter

| • Explosion-proof, applicable to harsh environments • Transmitting signals and multiple installation methods are available • Pipe diameter: DN6~DN1600 • Output: 4mA~20mA DC, 4mA~20mA DC+HART, RS485/Modbus, Profibus-DP, frequency, pulse output • Accuracy: ≤±0. 5%FS • Operating temperature: -20℃~60℃ |

• MFC608 Coriolis Mass Flowmeter

| • Applicable to measurement of multiple process variables such as mass flow, volume flow, density, temperature • Pipe diameter: DN4~DN300mm • Output: 4mA~20mA DC, RS485 output, pulse output • Accuracy level: 0.5/0.2/0.15 • Operating temperature: -196℃~85℃ |

Certificates

(DNV certification)

Value of the Solution

Pressure instruments on ships are primarily used to measuring and control pressure in systems such as fuel, lubrication, and cooling systems. Correct pressure ensures the effective operation of the system and the safety of the ship.

Level sensors are used to monitor and control the levels in fuel tanks, fresh water tanks, and sewage treatment systems. Accurate level readings are crucial for preventing oil spills, ensuring an adequate fresh water supply, and environmental protection.

Temperature transmitters are used to monitor the critical components of the ship, such as the temperature of the engine, boiler, and cooling systems. Proper temperature control helps improve efficiency, reduce wear, and prevent accidents caused by overheating.

Flowmeters are used to monitor the flow of fluids such as fuel, lubricating oil, and cooling water. They help ensure the proper flow of fluids in the system, thereby ensuring the normal operation and energy efficiency of the ship.

About Micro Sensor

Since its inception in 1971, Micro Sensor Co., Ltd. has been dedicated to the research and manufacturing of piezo-resistive pressure sensors. With over 50 years of design, development, and production experience, the company has emerged as a leading force in China’s semiconductor piezo-resistive pressure sensor industry. Micro Sensor’s product portfolio includes pressure sensors, pressure transmitters, level transmitters, temperature transmitters, and flow meters. Serving over 20,000 customers in more than 100 countries and regions, the company specializes in providing customized product solutions for various industries, including shipbuilding, gas distribution networks, petrochemicals, water resources management, municipal firefighting, smart heating, smart cities, and the food and pharmaceutical sectors.

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD