Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4736

Used For

Water Treatment, Electric Power, Environmental Protection, Hydraulic and Pneumatic Control Systems

Leave a MessageThe MPM4736 digital pressure transmitter performs precise measurement under the efficient and low-cost operation of the application system. While monitoring the pressure or liquid level, the MPM4736 can also measure the temperature information of the medium and the environment. It consumes no more than 10uA in auto-sleep mode. This results in longer battery life and lower maintenance costs. The wide voltage of this product supports multiple power supply methods. High-precision digital processing circuit plus special algorithm to achieve high-precision measurement. MPM4736 digital pressure transducer is suitable for temperature and pressure monitoring in industries such as environmental protection, papermaking, hydraulic pressure and pneumatic control systems.

Feature

• High-precision, multi-parameter measurement

• Extremely low power consumption, longer battery life

• Standard protocol, convenient networking

Specifications

• Measured range: -1bar…0bar~0.1bar…1000bar

• Overpressure: ≤1.5 times FS or 1100bar (min. value is valid)

• Total accuracy: ±0.25%FS(-10℃~70℃)

• Temperature accuracy:±0.5℃(-20℃~80℃)±0.75℃(-30℃~-20℃)

• Long-term stability: ±0.25%FS/year

• Compensation temperature: -10℃~70℃

• Operation temperature: -30℃~80℃

Image:

The MPM4736 digital pressure transmitter performs precise measurement under the efficient and low-cost operation of the application system. While monitoring the pressure or liquid level, the MPM4736 can also measure the temperature information of the medium and the environment. It consumes no more than 10uA in auto-sleep mode. This results in longer battery life and lower maintenance costs. The wide voltage of this product supports multiple power supply methods. High-precision digital processing circuit plus special algorithm to achieve high-precision measurement. MPM4736 digital pressure transducer is suitable for temperature and pressure monitoring in industries such as environmental protection, papermaking, hydraulic pressure and pneumatic control systems.

Feature

• High-precision, multi-parameter measurement

• Extremely low power consumption, longer battery life

• Standard protocol, convenient networking

Specifications

• Measured range: -1bar…0bar~0.1bar…1000bar

• Overpressure: ≤1.5 times FS or 1100bar (min. value is valid)

• Total accuracy: ±0.25%FS(-10℃~70℃)

• Temperature accuracy:±0.5℃(-20℃~80℃)±0.75℃(-30℃~-20℃)

• Long-term stability: ±0.25%FS/year

• Compensation temperature: -10℃~70℃

• Operation temperature: -30℃~80℃

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

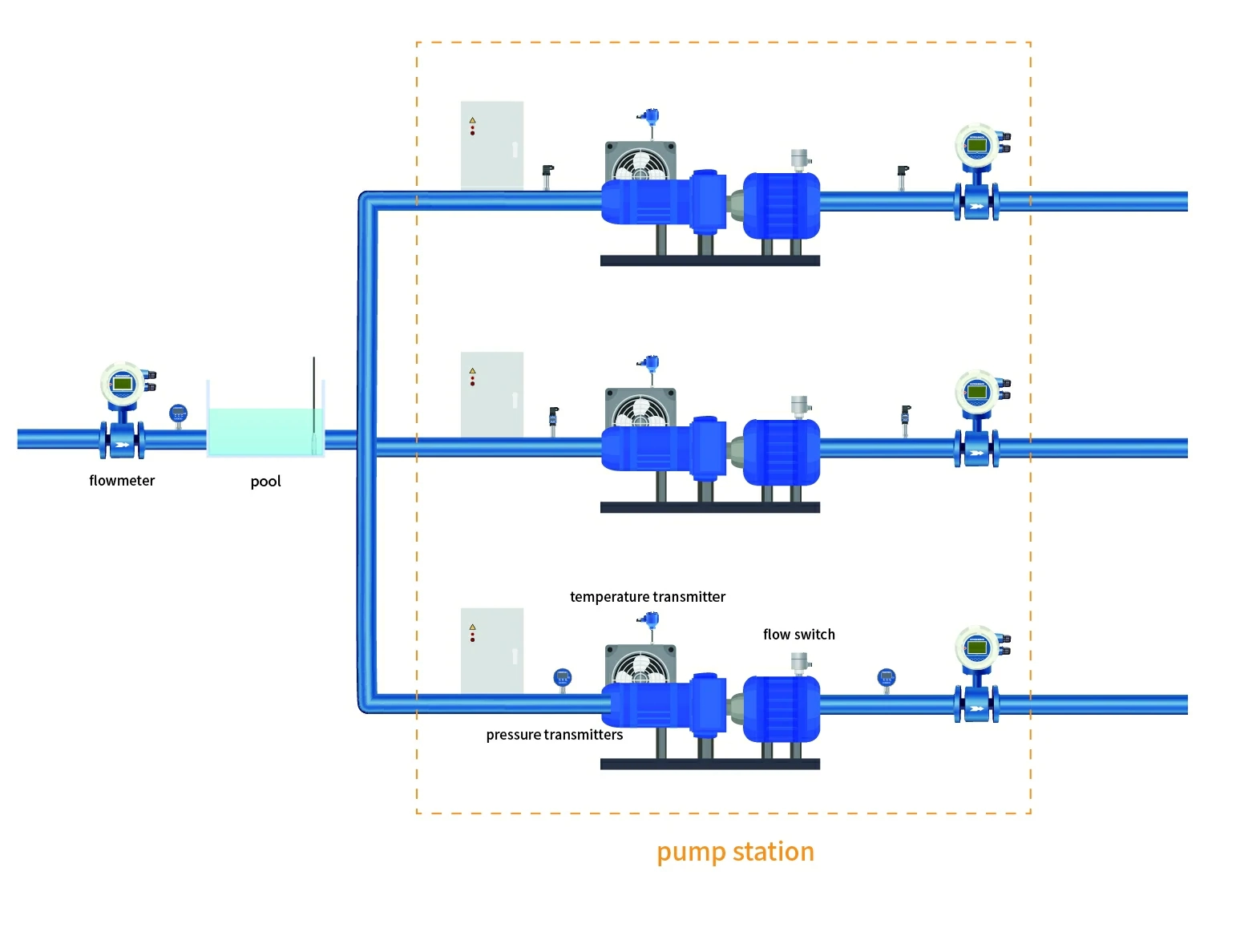

Irrigation and drainage pumping stations solve the problem of gravitational water diversion in irrigation areas, enabling cross-basin water transfer. MicroSensor provides real-time pressure and flow monitoring for inlet and outlet pipelines of these pumping stations, contributing to the accurate measurement of information-based irrigation areas and high-standard farmland construction.

more info...

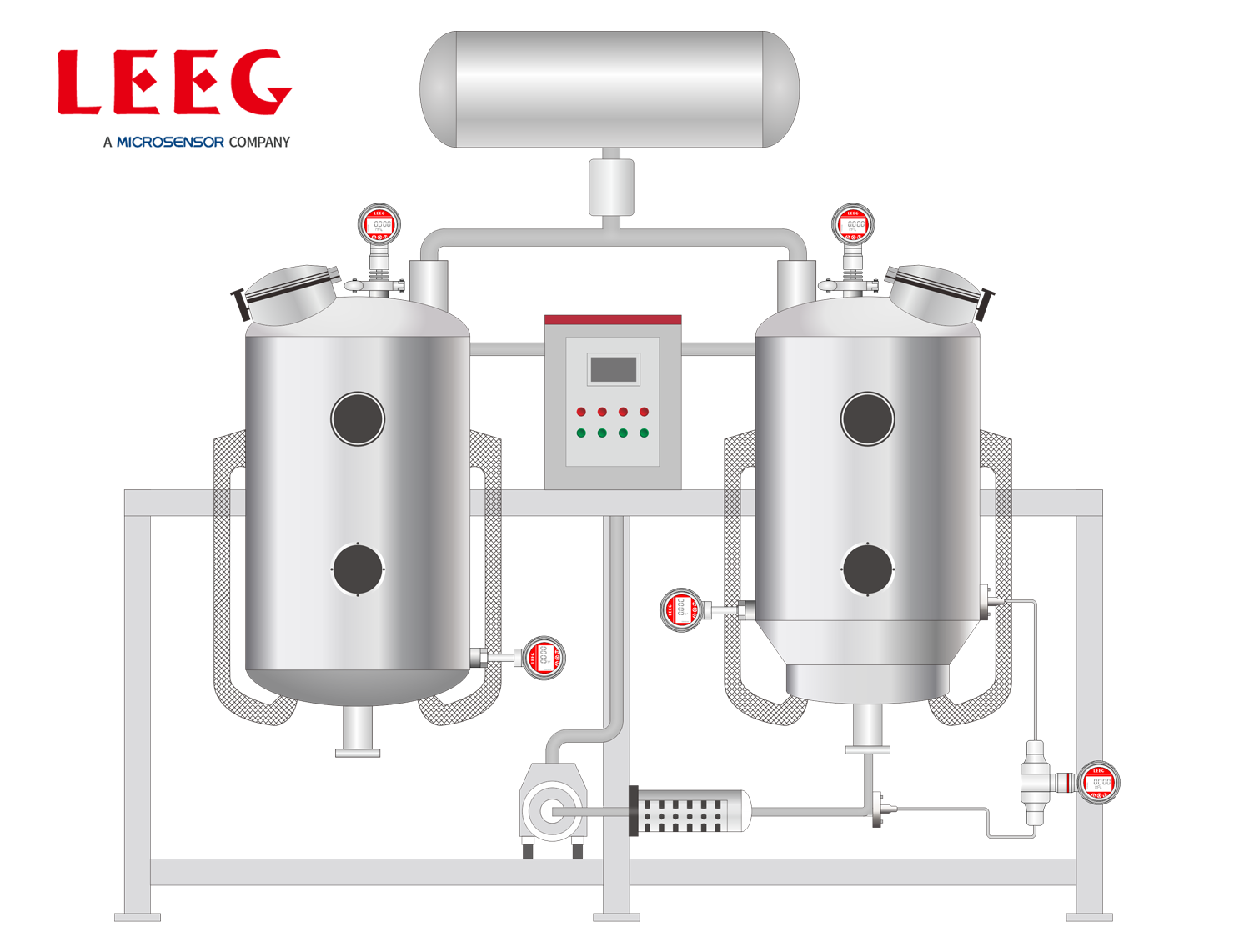

The production of different paste-like drugs uses a concentration process when processing raw materials. The evaporator features high temperature and vacuum. After the concentration process, it needs to be cleaned with efficient and strong chemical detergents. The pressure, temperature and level transmitters in the evaporator effectively ensure the normal and efficient operation of the concentration and washing process.

more info...

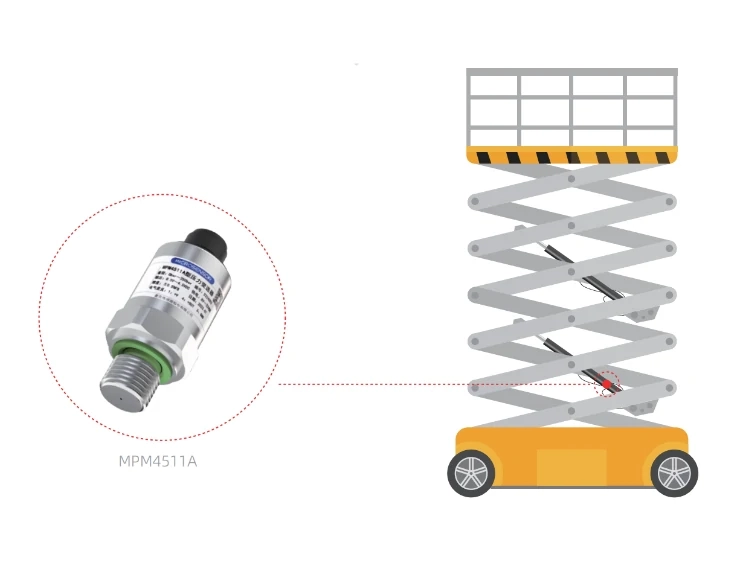

Aerial work platforms utilize hydraulic equipment for platform elevation to achieve high-altitude operations. In some fields, pressure transmitters are required to enable monitoring of operating conditions and fault diagnosis capabilities.

more info...