However, due to the danger of gas, it has higher requirements on the preparation process, container handling, storage, and transportation technology, etc.

Through various pressure transmitters, differential pressure transmitters and other sensing and monitoring instruments, real-time monitoring of the pressure values in the production, storage, supply and use of industrial gases, and realize gas production equipment and storage tanks through supporting systems. The automatic monitoring and adjustment of gas cylinders to keep the pressure value within the normal range is an important step to ensure safe production, optimize process management, and improve the level of automation.

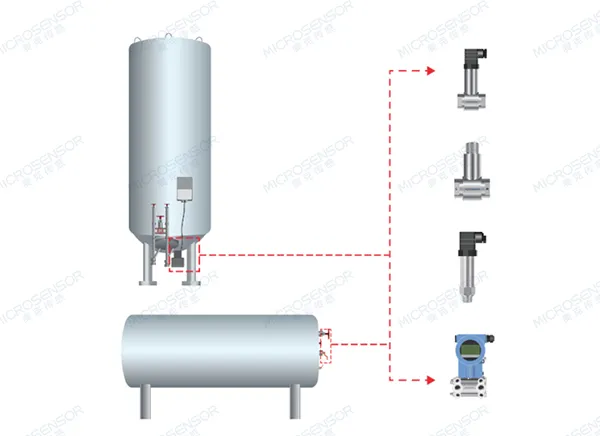

Vertical High-Pressure Deep-Cooled Bulk Storage Tank | Horizontal High-Pressure Deep-Cooled Storage Tank

The pressure transmitter is mainly used to measure the liquid level of liquid gas when measuring the storage tank. Differential pressure measurement is the most common and reliable way to measure the liquid level of cryogenic high-pressure bulk storage tanks. Its working principle is to obtain the liquid level value of the tank by measuring the pressure difference between the top and bottom of the tank through a differential pressure transmitter. The measured pressure value will finally be converted into the height value of the liquid level. In addition, the pressure sensor can also be used to measure the absolute pressure of the tank and the pressure before and after the cryopump to ensure the safe operation of the system.

4 Products Micro Sensor Can Offer for This Application

· Micro Sensor usually uses MDM4901FL differential pressure transmitter for oxygen pressure measurement. The product uses stainless steel 316L isolation diaphragm and is filled with fluorinated oil, which has better stability and can effectively prevent gas from oxidizing the diaphragm.

· At the same time, the MPM489FL pressure transmitter is available to be used in this application. The sensing element of the product is filled with fluorinated oil, and the "no oil" production process is adopted. It can measure gauge pressure, absolute pressure, and sealed gauge pressure, with short-circuit protection and reverse polarity protection. MPM489FL is safe and reliable and easy to use.

· In addition, the MDM4902FL I²C digital differential pressure transmitter is made of a diffused silicon piezoresistive differential pressure sensor and a stainless steel 316L isolation diaphragm. The product is filled with fluorinated oil with better stability, and features wide working temperature, high precision, stable performance and is convenient for adjustment. The standard I²C digital output makes the docking and expansion easy.

· Similarly, the MDM3051S-DP intelligent differential pressure transmitter is a high-precision, high-stability differential pressure transmitter with a wide range and intelligent output. It can be used to measure the liquid level, density, pressure, and flow measurement of the medium such as gas, steam, etc.

Compressed Gas Cylinder

Pressure Transmitters in Gas Cylinder Monitoring are generally used in the pressure monitoring of gas supply pipelines and gas supply tanks.

Pressure transmitters are responsible for pressure monitoring in gas cylinders and for providing signal output to indicate low tank pressures in system-critical applications to ensure gas cylinder safety. The pressure transmitter can also be integrated into the PLC alarm system to actively monitor the pressure of the cylinder to automatically control the switchover manifold. In addition, the pressure transmitter can also be connected to a telemetry gateway to remotely monitor pressure changes to prevent problems such as stockouts or leaking of gas cylinders. When pressure transmitters are used for medical oxygen monitoring, it is necessary to ensure that the product undergoes strict cleaning procedures and the oil filled in the sensor shall be fluorinated oil that is compatible with oxygen.

Micro Sensor provides MPM489FL pressure transmitter for this application. The pressure sensor of the product is filled with fluorinated oil and adopts the "no oil" production process. It can measure gauge pressure, absolute pressure, and sealed gauge pressure. It has short-circuited protection and reverse polarity protection. It is reliable, safe, and easy to use.

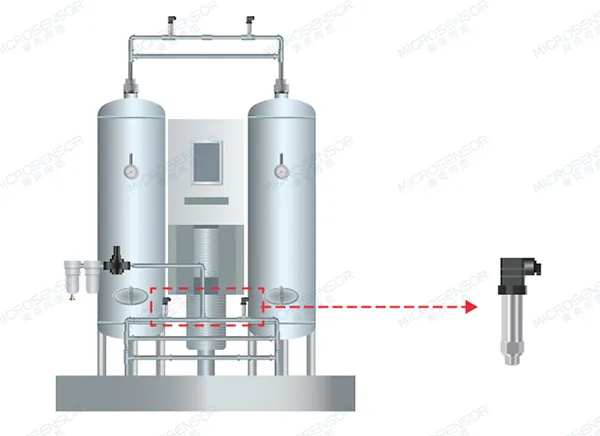

Nitrogen Generator/Oxygen Generator

Compared with storing nitrogen and oxygen in high-pressure cylinders, it is more efficient to directly produce and use nitrogen generators/oxygen generators.

The nitrogen generators/oxygen generators are mostly used in industries such as electronics, medical treatment, air-conditioning cold storage, food, and beverage. In addition to monitoring the pressure inside the container, the pressure transmitter on the nitrogen generator/oxygen generator is also used to monitor the pressure swing adsorption process often.

For this application, our MPM489FL pressure transmitter is suitable.

Micro Sensor can provide customized products and professional monitoring solutions according to the actual situation of different projects. We have a professional R&D team, ready to offer you unique service. Feel free to level messages below or email us via sales@microsensor.cn.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD