Flush Diaphragm Pressure Sensor

M20x1.5, R1/2, G1/2

0bar~1bar...35bar

Flush Diaphragm

MPM280F

Used For

Industrial Process Control, Level Measurement, Gas & Liquid Pressure Measurement

Leave a MessageMPM280F flat membrane pressure sensor is particular for food, medicine, and hygienic industries. The flush diaphragm can be in contact with the measuring medium over a large area. Even if the corrugated diaphragm has residual stains or fouling, it is easy to clean. The structure can effectively prolong the life of the sensor.

We provide male thread and clamp connection for optional. MPM280F sensor is packaged in a stainless steel 316L housing and sealed by FKM or silicon O-ring. Standard or customized in various mechanical and electrical configurations are available.

Feature

• Flush diaphragm

• Hygienic structure optional

• Negtive pressure measurement is available

Specification

• Size: Φ19x13.5mm

• Pressure range: 0bar ~ 0.35bar…350bar

• Power supply: ≤2.0mA DC

• Type: Gauge, Absolute and Sealed gauge

• Overpressure: 2 times FS

• Linearity: ±0.15 (Typ.)

• Repeatability: ±0.05 (Typ.)

Image:

MPM280F flat membrane pressure sensor is particular for food, medicine, and hygienic industries. The flush diaphragm can be in contact with the measuring medium over a large area. Even if the corrugated diaphragm has residual stains or fouling, it is easy to clean. The structure can effectively prolong the life of the sensor.

We provide male thread and clamp connection for optional. MPM280F sensor is packaged in a stainless steel 316L housing and sealed by FKM or silicon O-ring. Standard or customized in various mechanical and electrical configurations are available.

Feature

• Flush diaphragm

• Hygienic structure optional

• Negtive pressure measurement is available

Specification

• Size: Φ19x13.5mm

• Pressure range: 0bar ~ 0.35bar…350bar

• Power supply: ≤2.0mA DC

• Type: Gauge, Absolute and Sealed gauge

• Overpressure: 2 times FS

• Linearity: ±0.15 (Typ.)

• Repeatability: ±0.05 (Typ.)

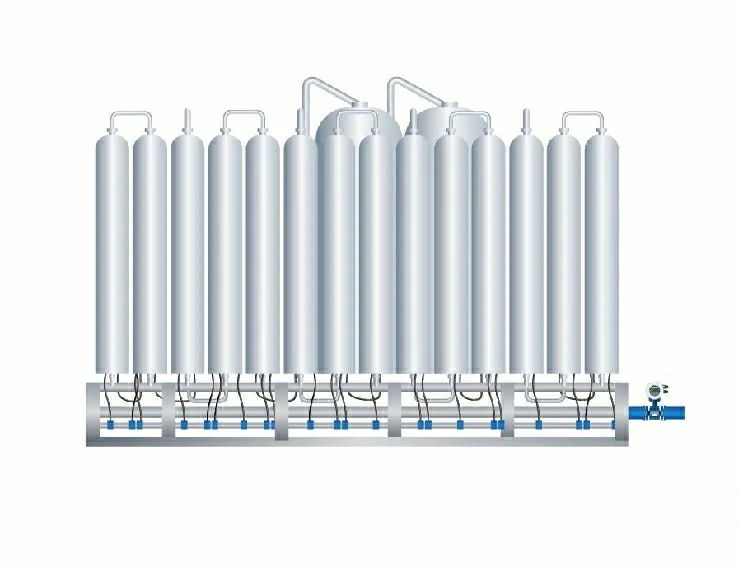

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...

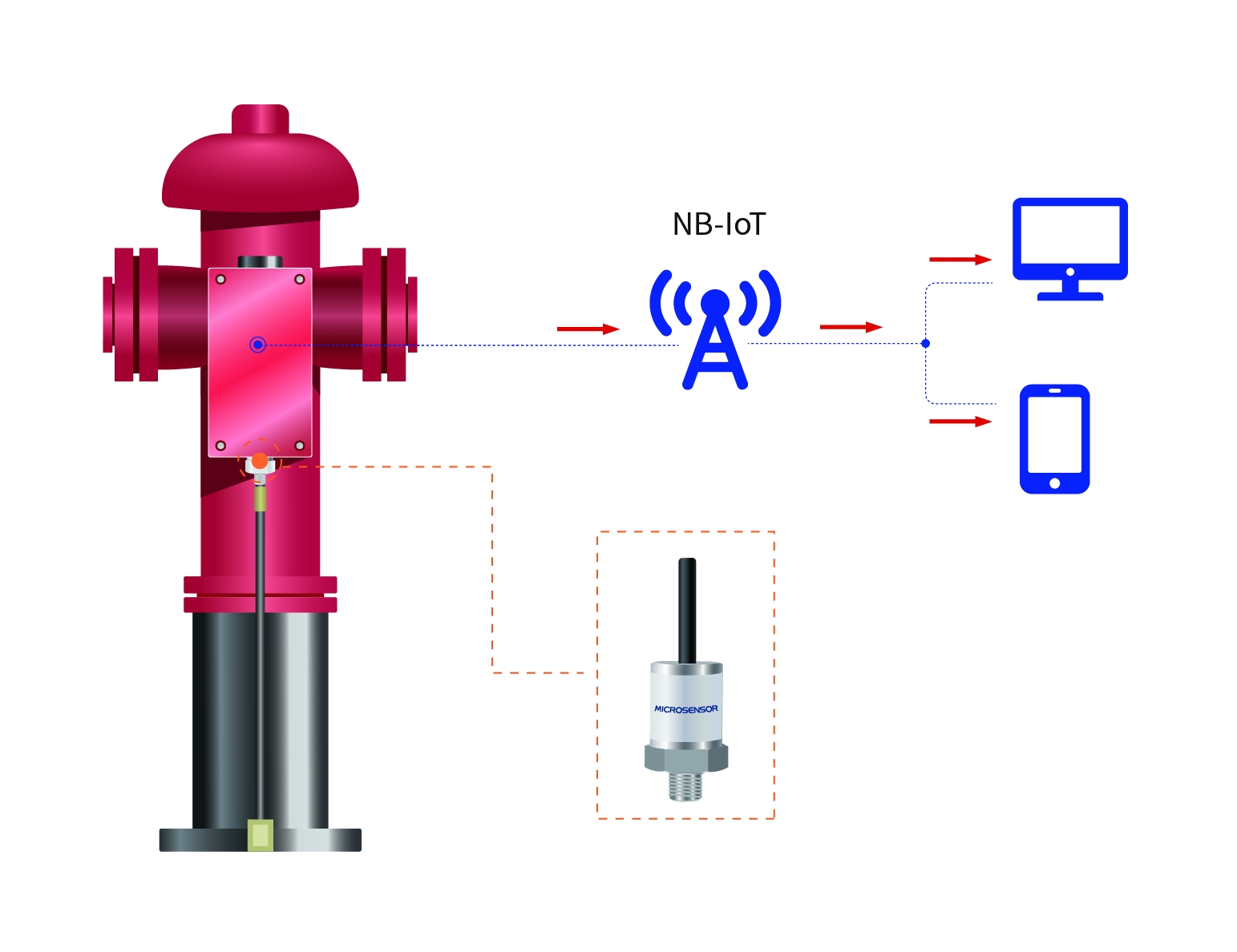

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...

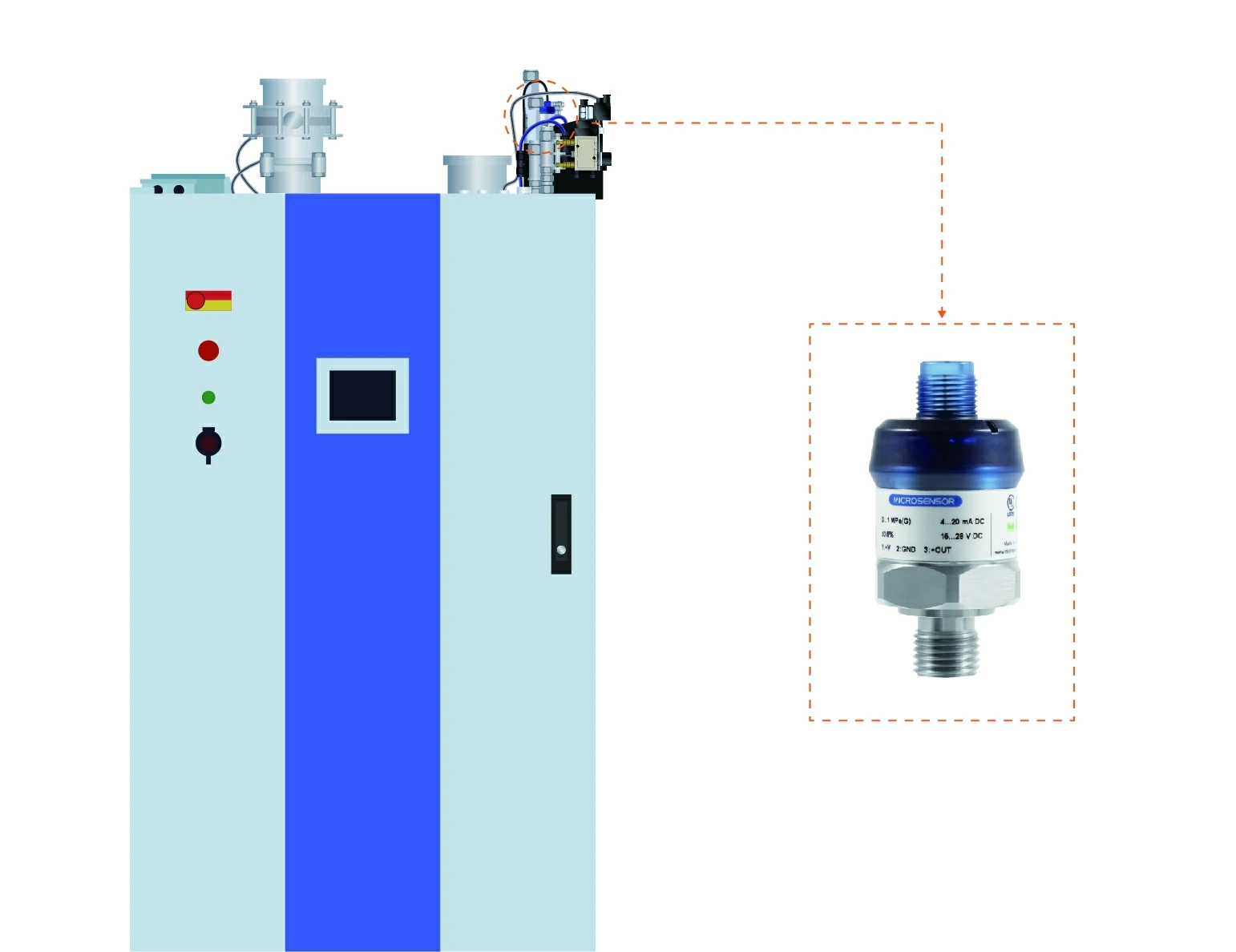

The plasma in a plasma cleaning machine is a state of matter, usually composed of process gases. Therefore, specially designed pressure transmitters must be installed in the relevant gas circuits of the plasma cleaning system to monitor and provide feedback on production data.

more info...

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...