Piezoresistive Pressure Sensor

Φ19x11.5mm

0bar~0.35bar…1000bar

Constant Voltage Supply

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM289

Used For

liquid pressure measurement

Leave a MessageThe MPM289 absolute pressure sensor is manufactured on a mass production line to meet general usage requirements. To ensure product quality for large quantity production, Micro Sensor strict adhere to the ISO9001:2015 management system. Along with mature production techniques, the pressure transducer's long-term stable performance is guaranteed. Also, the price is very attractive for bulk orders! The MPM289 sensor is widely used in various fields for pressure measurement, thanks to its constant current power supply and isolated construction, which enables measurement of various media.

Features

• Pressure range 0bar~ 0.35bar…1000bar

• standard Φ19mm OEM pressure sensor

• All stainless steel 316L

• Wide temperature compensation 0℃~70℃

Specifications

• Power Supply: ≤2.0mA DC

• Output Impedance: 3.5kΩ~6kΩ

• Insulation Resistor: 100MΩ@100V DC

• Overpressure: 2 times FS or 1100bar(min.value is valid)

Image:

The MPM289 absolute pressure sensor is manufactured on a mass production line to meet general usage requirements. To ensure product quality for large quantity production, Micro Sensor strict adhere to the ISO9001:2015 management system. Along with mature production techniques, the pressure transducer's long-term stable performance is guaranteed. Also, the price is very attractive for bulk orders! The MPM289 sensor is widely used in various fields for pressure measurement, thanks to its constant current power supply and isolated construction, which enables measurement of various media.

Features

• Pressure range 0bar~ 0.35bar…1000bar

• standard Φ19mm OEM pressure sensor

• All stainless steel 316L

• Wide temperature compensation 0℃~70℃

Specifications

• Power Supply: ≤2.0mA DC

• Output Impedance: 3.5kΩ~6kΩ

• Insulation Resistor: 100MΩ@100V DC

• Overpressure: 2 times FS or 1100bar(min.value is valid)

Φ19x11.5mm

Pressure range -1bar…0bar~0.07bar… 1000bar

Silicone/Fluorocarbon oil filling options

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

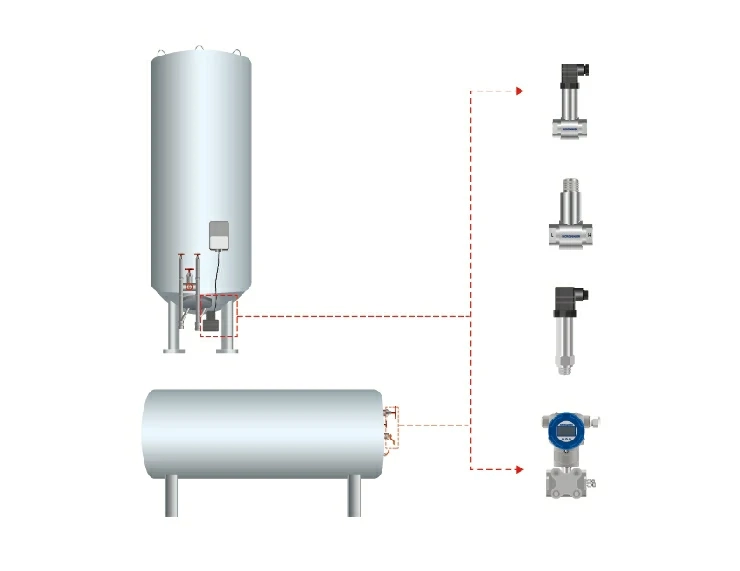

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

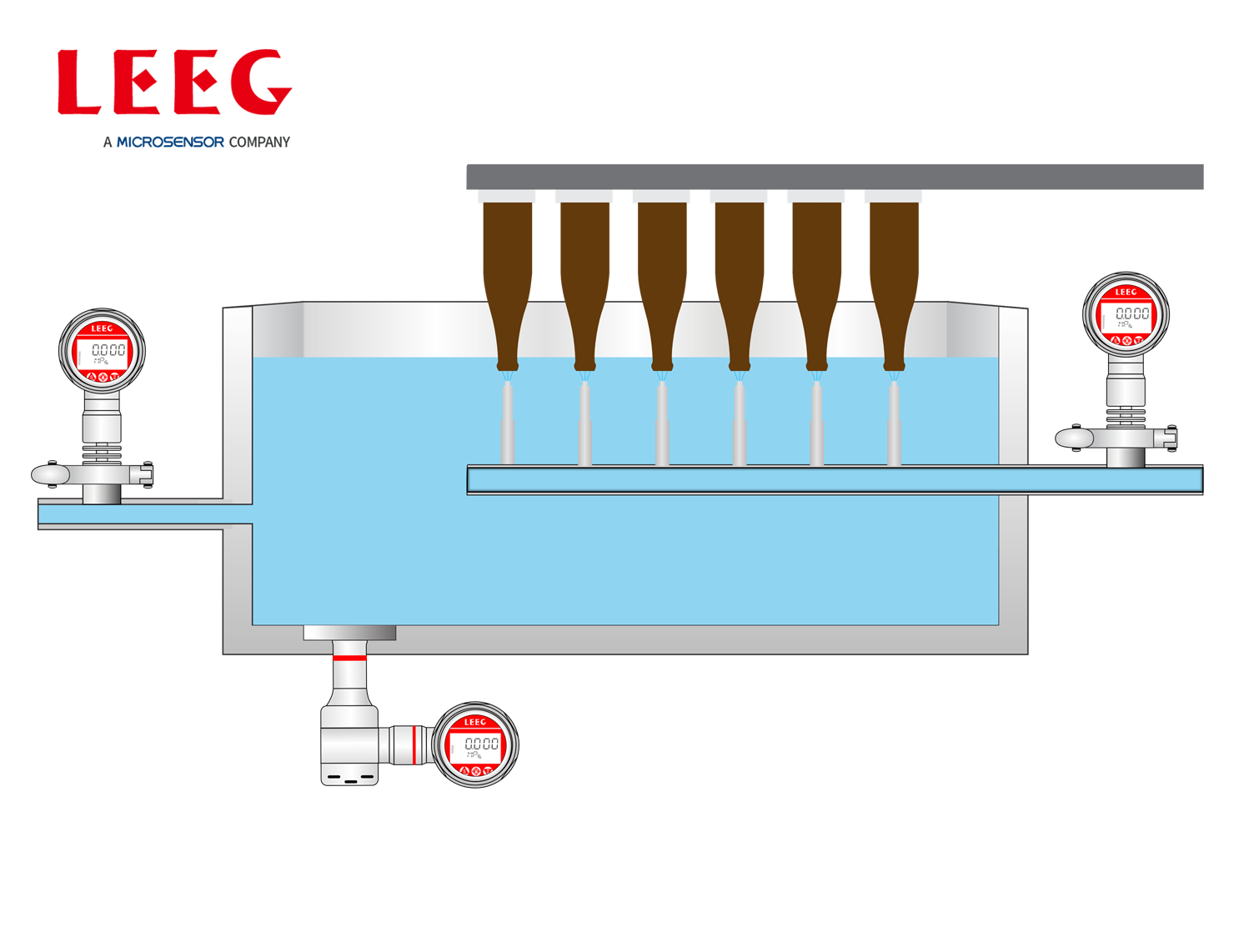

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...

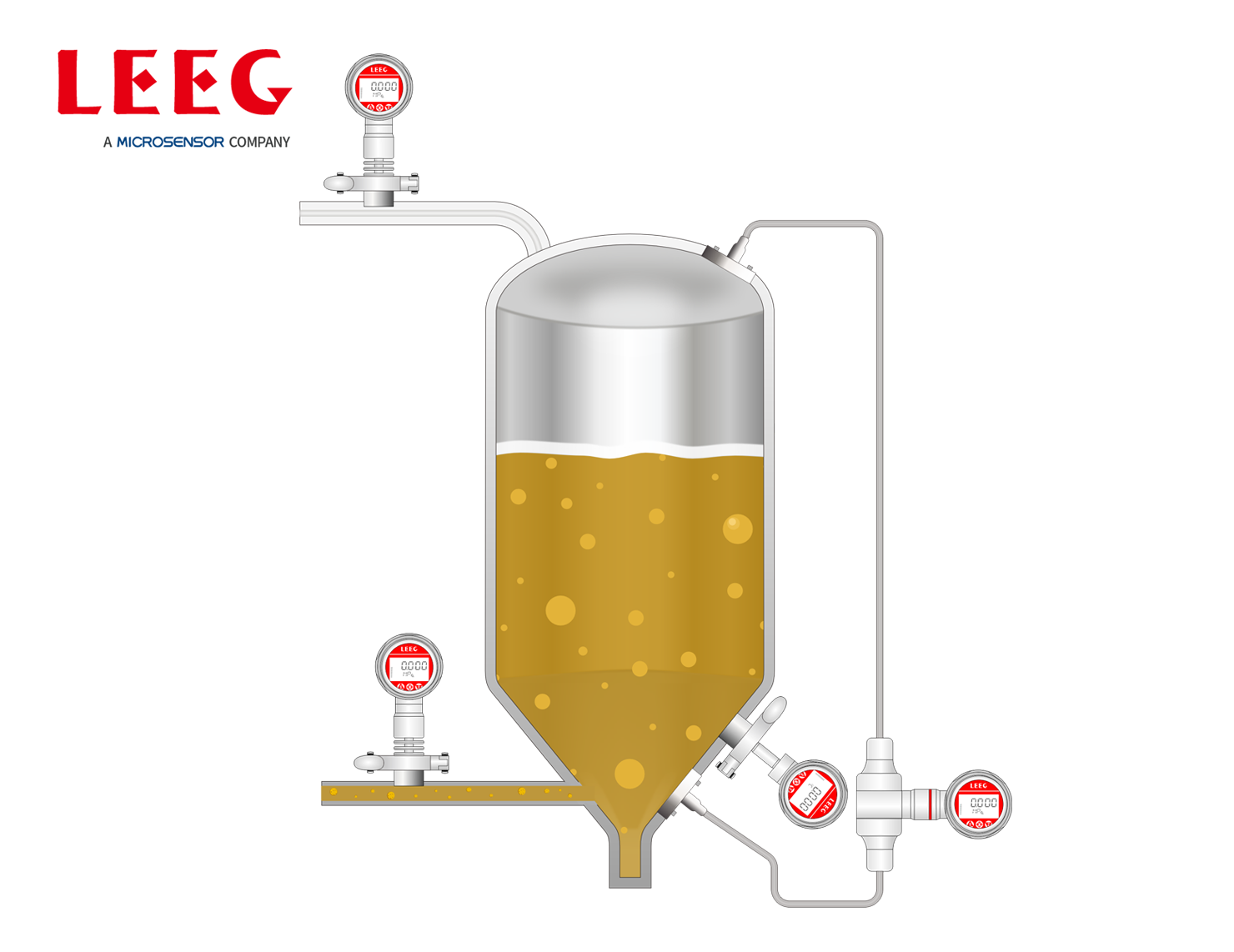

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

more info...