Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4810

Used For

Hot Spring Level & Temperature Measurement, Under-Ground Hot Water Measurement

Leave a MessageMPM4810 High Temperature Level Transmitter is a high-precision high temperature resistant liquid level measurement product. The whole machine adopts fully sealed stainless steel welding structure. The liquid level transmitter can work for a long time in a high-temperature environment of 125°C for pressure and temperature measurement. The stainless steel cap at the bottom of the product is detachable, which can prevent accidental damage to the diaphragm and facilitate regular cleaning.

MPM4810 Level Transmitter is an input measurement method, mainly used for the measurement of hot spring water and groundwater.

Feature

• High precision & high-temperature resistance

• Measurement of liquids temperature up to 125 ℃

• Compatible with stainless steel material

• Digital temperature compensation and non-linearity correction

Specification

• Range Level: 0m~5m…200m H2O

• Temperature: 0℃ ~125℃

• Overpressure: 1.5 times FS

• Pressure Type: Absolute

• Accuracy: Level:±0.5%FS (including nonlinearity, repeatability and hysteresis); Temperature:±2℃

• Power Supply: 10V~30V DC

• Output Signal: 4mA~20mA DC

• Operation Temp.: 0℃ ~125℃

• Temp.Compensation: 0℃ ~125℃

• Long Term Stability: ±0.35%FS/Year

Image:

MPM4810 High Temperature Level Transmitter is a high-precision high temperature resistant liquid level measurement product. The whole machine adopts fully sealed stainless steel welding structure. The liquid level transmitter can work for a long time in a high-temperature environment of 125°C for pressure and temperature measurement. The stainless steel cap at the bottom of the product is detachable, which can prevent accidental damage to the diaphragm and facilitate regular cleaning.

MPM4810 Level Transmitter is an input measurement method, mainly used for the measurement of hot spring water and groundwater.

Feature

• High precision & high-temperature resistance

• Measurement of liquids temperature up to 125 ℃

• Compatible with stainless steel material

• Digital temperature compensation and non-linearity correction

Specification

• Range Level: 0m~5m…200m H2O

• Temperature: 0℃ ~125℃

• Overpressure: 1.5 times FS

• Pressure Type: Absolute

• Accuracy: Level:±0.5%FS (including nonlinearity, repeatability and hysteresis); Temperature:±2℃

• Power Supply: 10V~30V DC

• Output Signal: 4mA~20mA DC

• Operation Temp.: 0℃ ~125℃

• Temp.Compensation: 0℃ ~125℃

• Long Term Stability: ±0.35%FS/Year

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

High-speed paper mills use a vacuum system with turbine blowers to facilitate dewatering. The vacuum level, which is controlled by motor speed, must be continuously monitored. In addition, to ensure safe vacuum pump/blower operation, the lubrication status of bearings is maintained by measuring lubricant pressure and reservoir level.

more info...

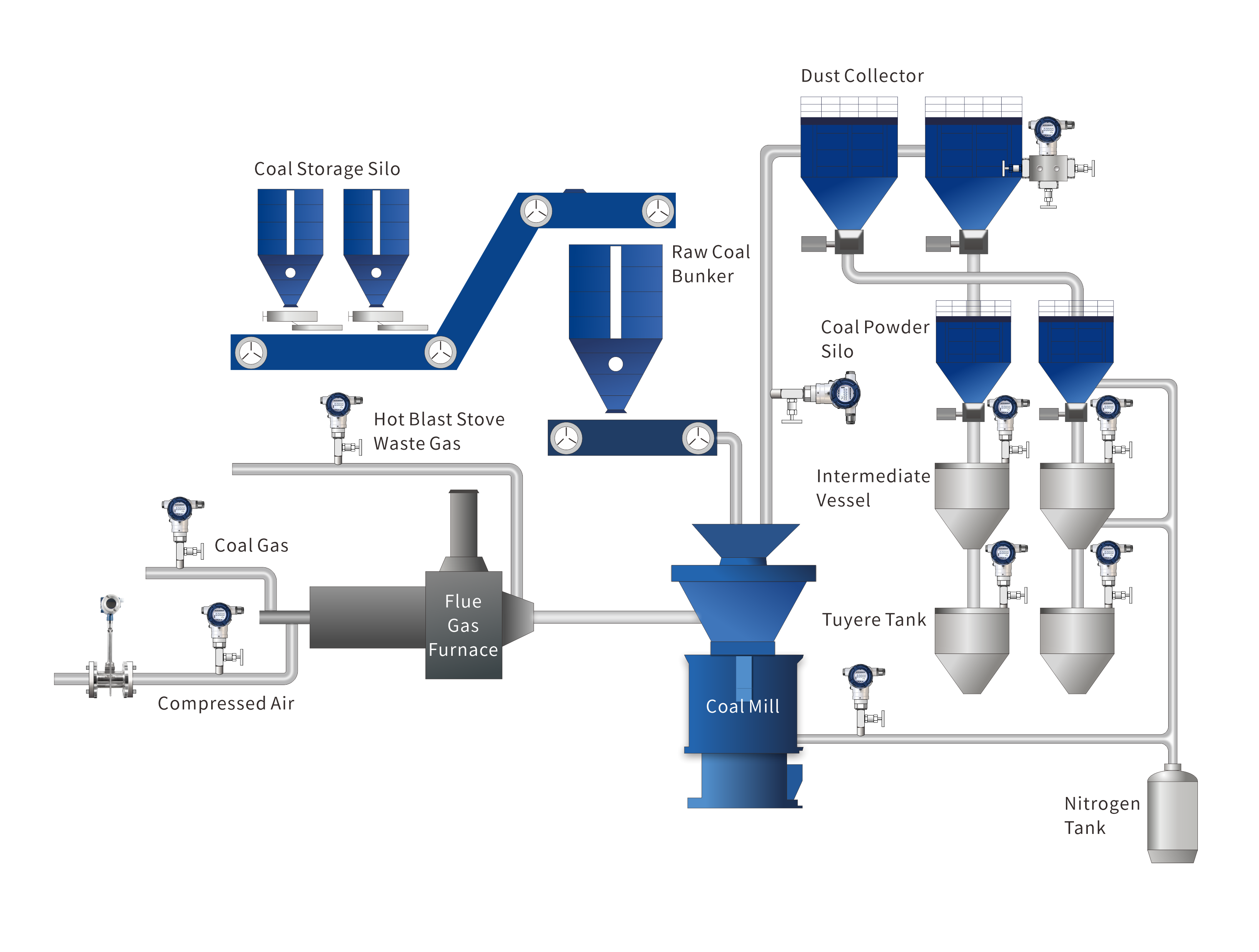

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the metallurgy industry to ensure smelting process efficiency and product quality. In the demanding high-temperature, high-pressure, and harsh environments of the metallurgy industry, Micro Sensor comprehensive monitoring solutions provide real-time data acquisition and precise regulation by integrating smart control systems and advanced sensor technologies. These systems optimize metal production processes for safe and effective operations.

more info...

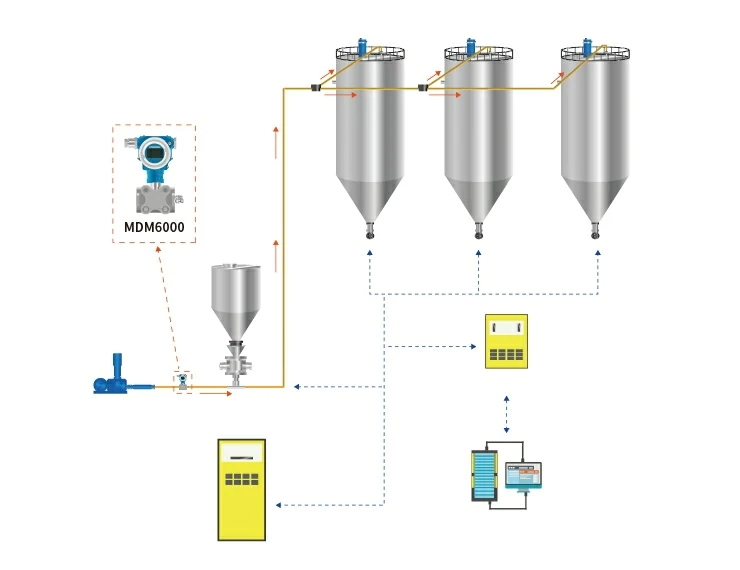

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...