Flow Switch

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

MFE600C

Used For

Chemical Industry, Water Supply and Drainage, Sewage Treatment

Leave a MessageMFE600C Insert Type Electromagnetic Flow Meter is a new type of flow measuring instrument based on the advantages of pipeline installation electromagnetic flow. MFE600C electromagnetic meter avoids the defects of difficult installation and high cost in large-diameter pipelines. The characteristics of opening under pressure and installation under pressure can realize construction and installation without stopping water.

MicroSensor has a professional electromagnetic flowmeter production equipment line with an annual production capacity of nearly 10,000 flowmeters. There are two sets of flow calibration devices on the production line. MFE600C has CE certification. Split and one-piece structures are optional. The MFE600C Insert Type Flow Meter finds extensive application in the chemical industry, as well as in water supply, drainage, sewage treatment, and various other sectors.

Features

• Split type and integrated type optional

• IP65 and IP68 degree of protection optional

• Widescreen LCD on-site display

• Flow upper limit, lower limit alarm output

Image:

MFE600C Insert Type Electromagnetic Flow Meter is a new type of flow measuring instrument based on the advantages of pipeline installation electromagnetic flow. MFE600C electromagnetic meter avoids the defects of difficult installation and high cost in large-diameter pipelines. The characteristics of opening under pressure and installation under pressure can realize construction and installation without stopping water.

MicroSensor has a professional electromagnetic flowmeter production equipment line with an annual production capacity of nearly 10,000 flowmeters. There are two sets of flow calibration devices on the production line. MFE600C has CE certification. Split and one-piece structures are optional. The MFE600C Insert Type Flow Meter finds extensive application in the chemical industry, as well as in water supply, drainage, sewage treatment, and various other sectors.

Features

• Split type and integrated type optional

• IP65 and IP68 degree of protection optional

• Widescreen LCD on-site display

• Flow upper limit, lower limit alarm output

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

Flange type: DN6~DN1600

Flange, Sanitary, Threaded, Clamping type available

Battery-powered, solar-powered optional

Diameter: DN25 ~ DN400

Nominal pressure: 0.6MPa/1.6MPa/4.0MPa

Lining material: Neoprene, Polyurethane Rubber, F4, F46

Electrode material: 316L, Ti, HB/HC, Ta, WC, Pt

Structure type: separated type, integrated type

The measurement accuracy will not be influenced by changes of fluid density, viscosity, temperature, pressure and electrical conductivity

Open flow without moving parts in measuring pipe, no pressure loss

Corrosion- and wear-resistant electrode and lining materials available

Multi-electrode structure, high precision

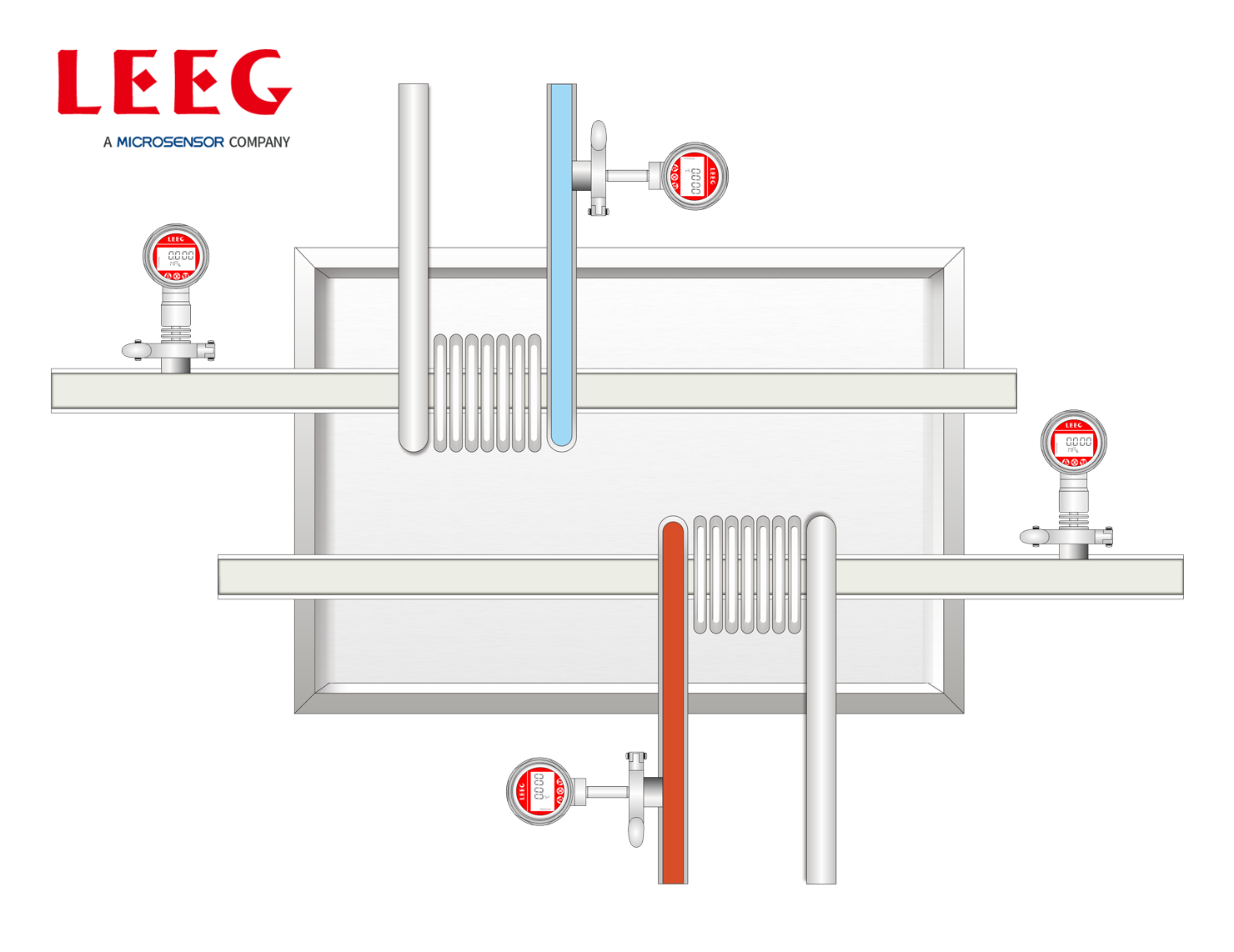

In beverage production and dairy processing, liquids are heated to specified temperatures through heat exchange, followed by rapid cooling to eradicate pathogens and prolong shelf life. Multiple stages such as heating and cooling of wort ensure that beer reaches the appropriate temperature for yeast cultivation. Both the cooler and preheater require monitoring of temperatures in the cooling and preheating tubes, as well as the pressure in the food pipelines.

more info...

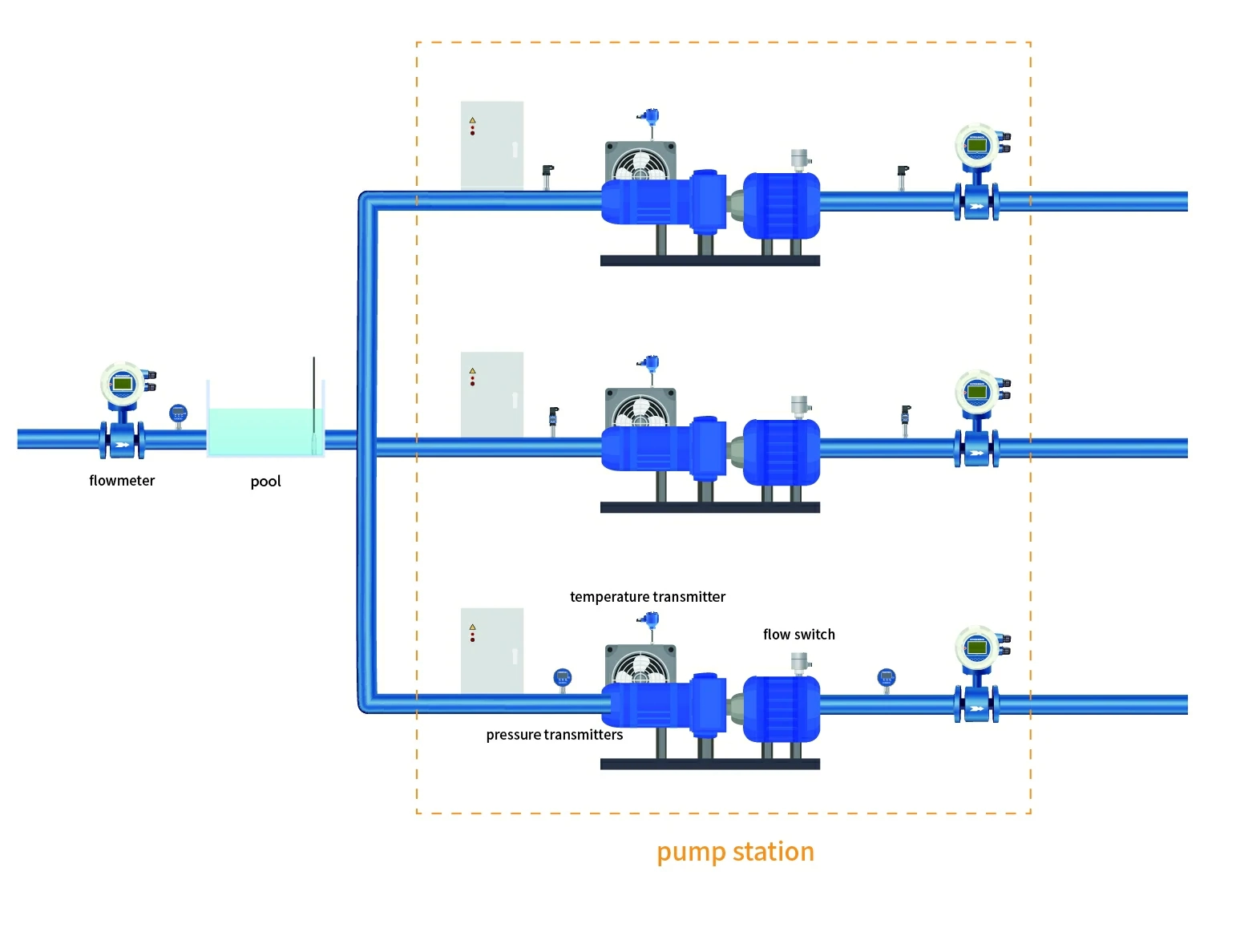

Irrigation and drainage pumping stations solve the problem of gravitational water diversion in irrigation areas, enabling cross-basin water transfer. MicroSensor provides real-time pressure and flow monitoring for inlet and outlet pipelines of these pumping stations, contributing to the accurate measurement of information-based irrigation areas and high-standard farmland construction.

more info...

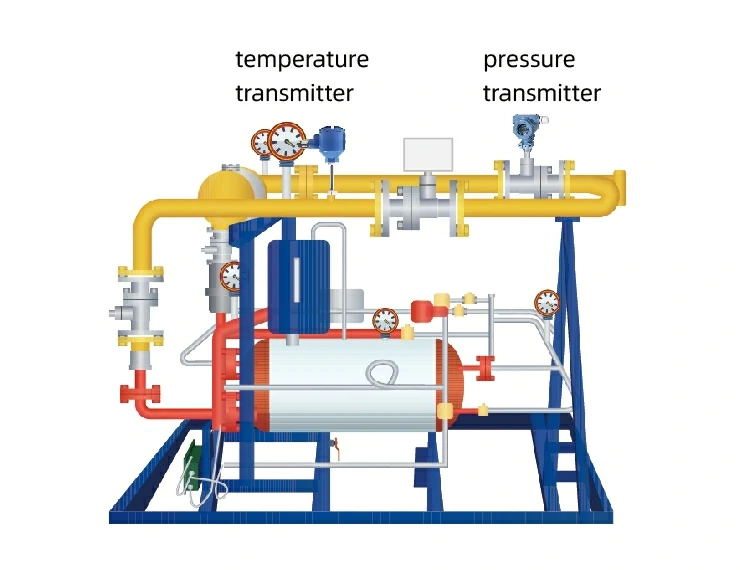

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...

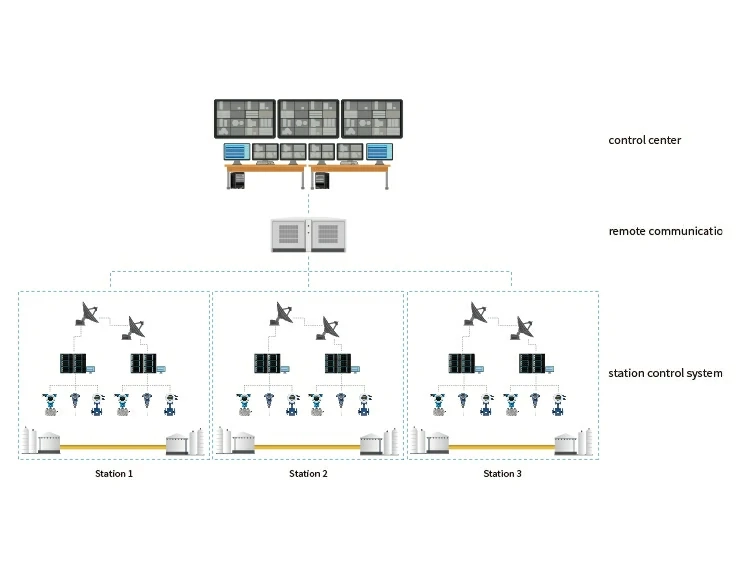

During the process of oil and gas transportation, it is necessary to collect and analyze production and security data related to pipelines and production sites, and generally a supporting SCADA system needs to be built simultaneously. The SCADA system can monitor, control and manage the flow rate, pressure and temperature of the entire pipeline in real time, in order to achieve safe transportation, reduce consumption and improve economic efficiency.

more info...