The installation of an electromagnetic flowmeter is a complex process that requires careful consideration to ensure accuracy and long-term stable operation of electromagnetic flow measurement.

Precautions for installing electromagnetic flowmeter

1. The electromagnetic flowmeter must be guaranteed to work under full pipe conditions. If the pipe is not full or empty, the flowmeter will not work normally.

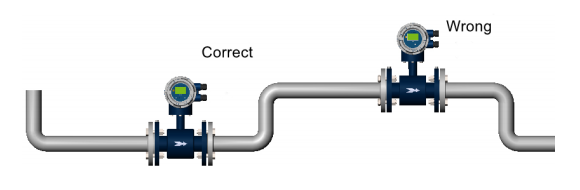

2. The electromagnetic water flow meter cannot be installed at the high point of the pipe. As shown in the Figure 1:

3. During installation, the direction of liquid flow should generally be consistent with the direction of the arrow on the product.

4. The electromagnetic flowmeter can be installed horizontally and vertically. Generally, when installed horizontally, the axis of the measuring electrode should be kept approximately horizontal.

5. There should be no large vibration source near the installation site. Reinforcement measures should be taken on both sides of the instrument to stabilize the nearby pipelines to prevent the flowmeter from receiving stress due to pipeline vibration, impact and contraction.

6. The electromagnetic flowmeter cannot be installed near sources that are prone to inductive interference or strong interference, such as motors, transformers, pumps, etc.

What are the straight pipe requirements for a magnetic flow meter?

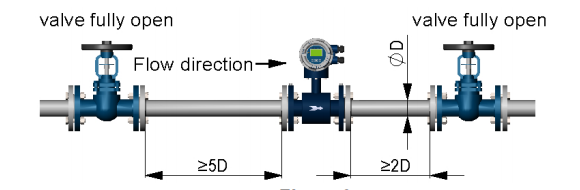

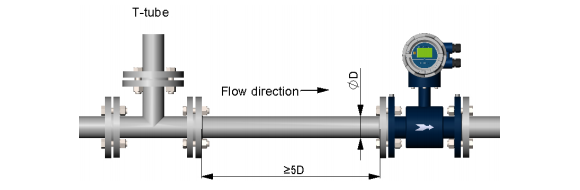

The straight pipe requirements depend on the different installation location. The electromagnetic flowmeter is recommended to be installed in the pipeline as below:

| Installation Location | Installation Requirements |

| installed between two valves |

|

| installed at the back end of the T-tube |

|

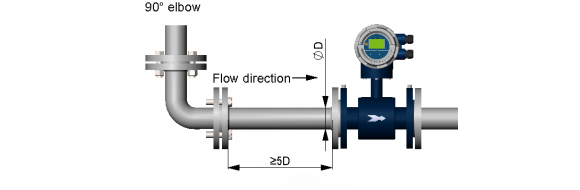

| installed at the back end of the 90°elbow pipe |

|

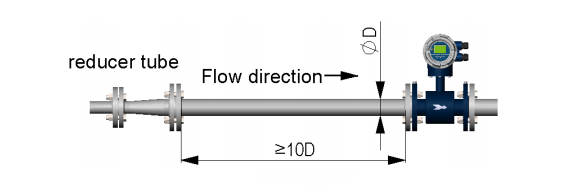

| at the back end of the expanded diameter pipe |

|

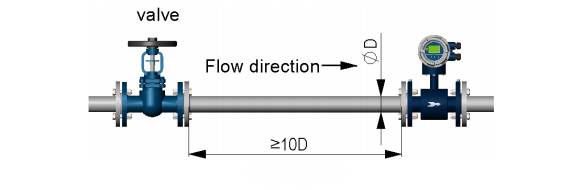

| installed at the back end of the valve (the valve is not fully open) |

|

Can threaded electromagnetic flowmeters use internal threads?

A: No. The default is external threads. Internal threads will cause the lining to come off. Adapters can meet this requirement.

Can inline-type electromagnetic flowmeters be used in a negative pressure environment?

A: It is generally not recommended to use inline type electromagnetic flowmeters in a negative pressure environment. Excessive negative pressure may cause the electrode to come off the lining and contact the housing to form a circuit conduction.

How to protect electromagnetic flowmeters from lightning?

1. Grounding: This is the most basic and important lightning protection measure. Ensure that both ends of the electromagnetic flowmeter sensor are well grounded. This prevents voltage transients and surges caused by lightning from damaging the instruments.

2. Shielding: The signal cable of the electromagnetic flowmeter must be sheathed with a galvanized pipe. The length cannot exceed 50 meters. This can reduce the interference and damage caused by lightning through the signal line.

3. Equipotential connection: Connect all potentially energized parts (such as sensors, transmitters, etc.) to a common low-impedance ground wire. These parts can be at the same potential level when lightning strikes, thereby avoiding the generation of local high voltage.

4. Lightning arrester: Installing lightning arresters on the power cable and signal cable of the electromagnetic flowmeter. The length of the lightning arrester grounding wire cannot exceed 1 meter, and the cross-sectional area should be greater than 6 square millimeters of multi-strand copper core insulated wire.

The above comprehensive measures effectively improve the safety and stability of the electromagnetic flowmeter under severe weather conditions.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD