Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

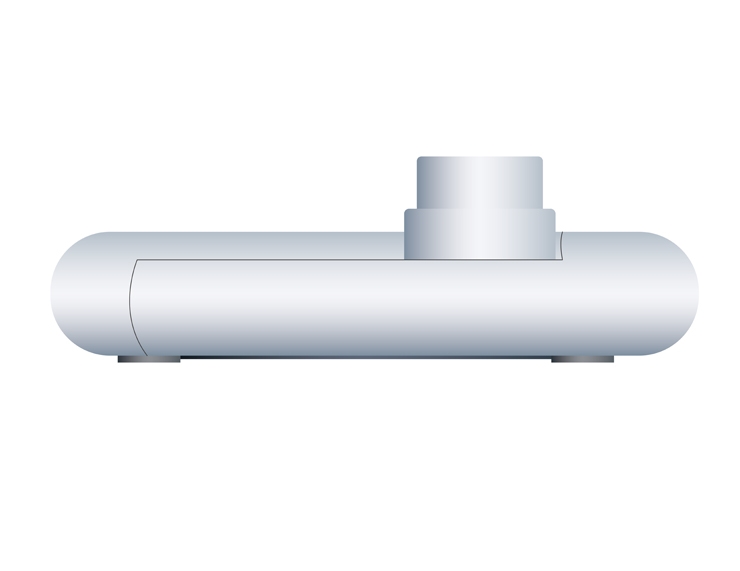

MPM4700

Used For

Pharmaceutical and Metallurgical Industries, Power Generation and Mining Industry, Urban Water Supply and Drainage

Leave a MessageMPM4700 Intelligent Level Transmitter is a two-wire liquid level measurement sensor with RS485 communication interface or HART communication protocol. This digital level sensor can be directly thrown into liquid for long-term use. MPM4700 adopts precision digital temperature compensation technology and nonlinear correction technology. The integrated structure provides convenience for on-site installation and use. It has obtained ROHS certification and complies with CCS requirements.

The MPM4700 pressure level transmitter provides precise and reliable level measurements for a wide range of tanks, silos, and vessels.

Feature

• Integrated fully sealed structure resistant to harsh environments

• Compatible with various output signals and communication protocols

• 0m~200m wide level measurement range

• CE, RoHS, CCS, and DNV approved

Specifications

• Range: 0mH2O ~ 1mH2O…200mH2O

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute

• Accuracy: ±0.1%FS, ±0.25%FS, ±0.5%FS

• Long-term Stability: ≤ ±0.2% FS/ year

• Compensated Temperature: -10℃ ~ 70℃

• Application Temperature:

-20℃ ~ 60℃ (Intrinsic safety type)

-20℃ ~ 70℃ (cable material: PE, PVC)

-20℃ ~ 80℃ (cable material: PUR)

Image:

MPM4700 Intelligent Level Transmitter is a two-wire liquid level measurement sensor with RS485 communication interface or HART communication protocol. This digital level sensor can be directly thrown into liquid for long-term use. MPM4700 adopts precision digital temperature compensation technology and nonlinear correction technology. The integrated structure provides convenience for on-site installation and use. It has obtained ROHS certification and complies with CCS requirements.

The MPM4700 pressure level transmitter provides precise and reliable level measurements for a wide range of tanks, silos, and vessels.

Feature

• Integrated fully sealed structure resistant to harsh environments

• Compatible with various output signals and communication protocols

• 0m~200m wide level measurement range

• CE, RoHS, CCS, and DNV approved

Specifications

• Range: 0mH2O ~ 1mH2O…200mH2O

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute

• Accuracy: ±0.1%FS, ±0.25%FS, ±0.5%FS

• Long-term Stability: ≤ ±0.2% FS/ year

• Compensated Temperature: -10℃ ~ 70℃

• Application Temperature:

-20℃ ~ 60℃ (Intrinsic safety type)

-20℃ ~ 70℃ (cable material: PE, PVC)

-20℃ ~ 80℃ (cable material: PUR)

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

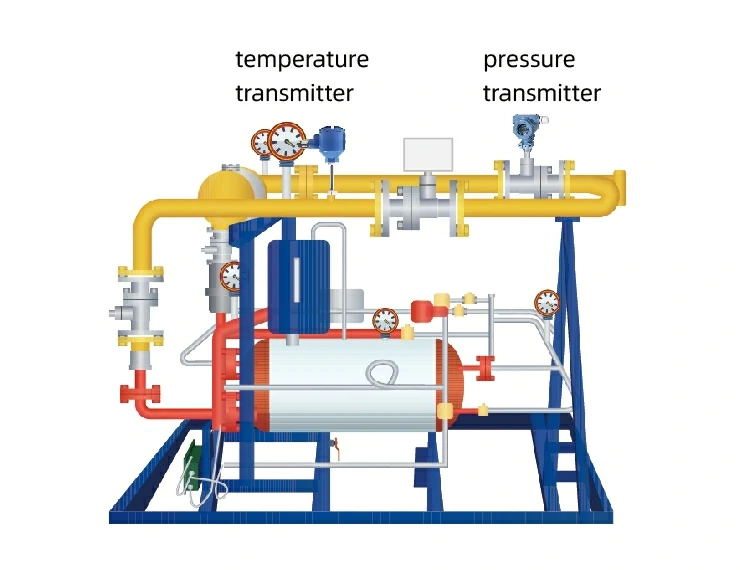

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

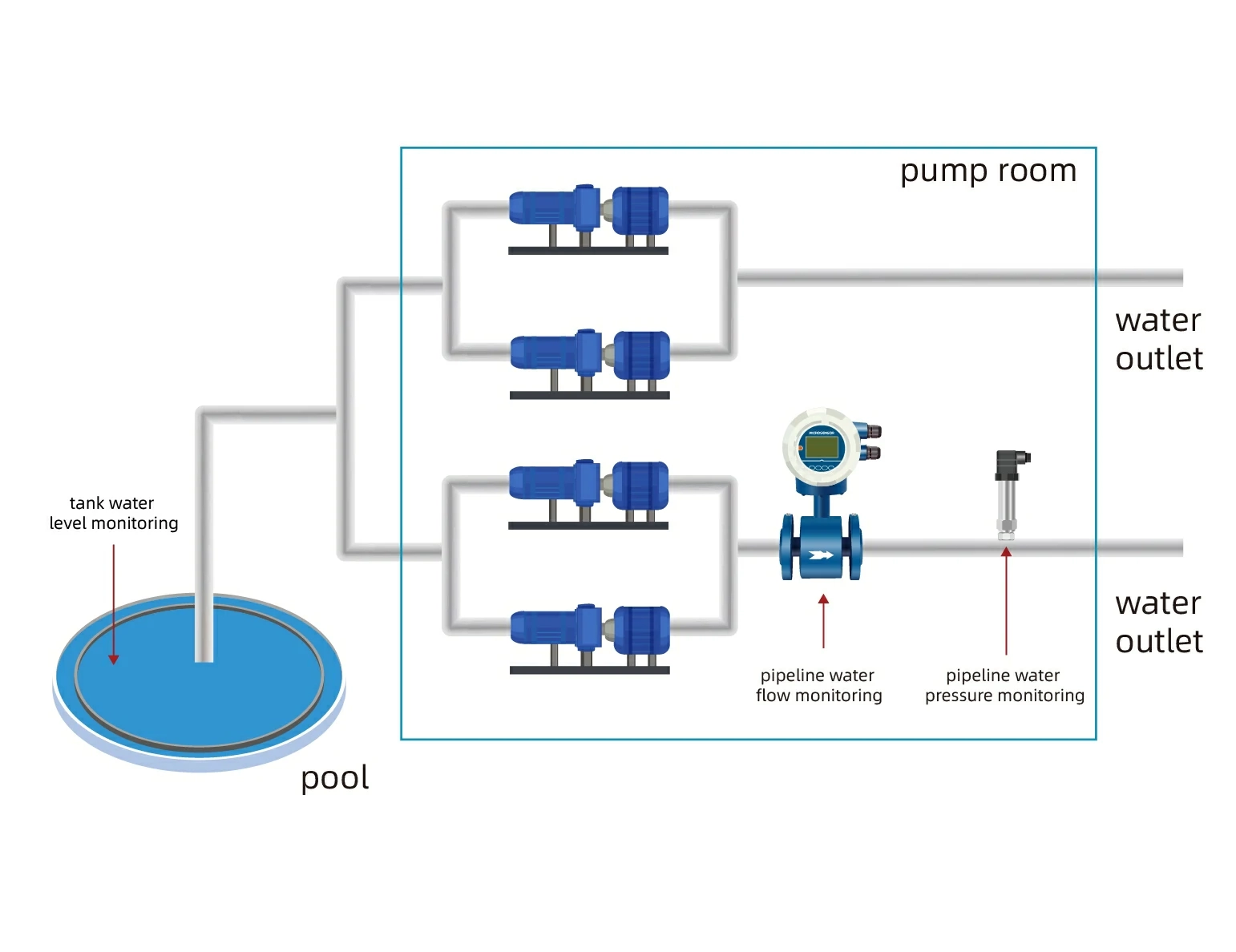

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

Perfect coffee needs pressure. Water and steam pressure monitoring of the coffee machine ensures safe and high-quality coffee production. Accurately measuring pressure is required during the coffee bean extraction, hot water delivery, and cleaning of coffee machines.

more info...