IIC Pressure Sensor

Range:0bar~0.07bar…1000bar

Accuracy: ±0.25%FS

Digital IIC output

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM3801A

Used For

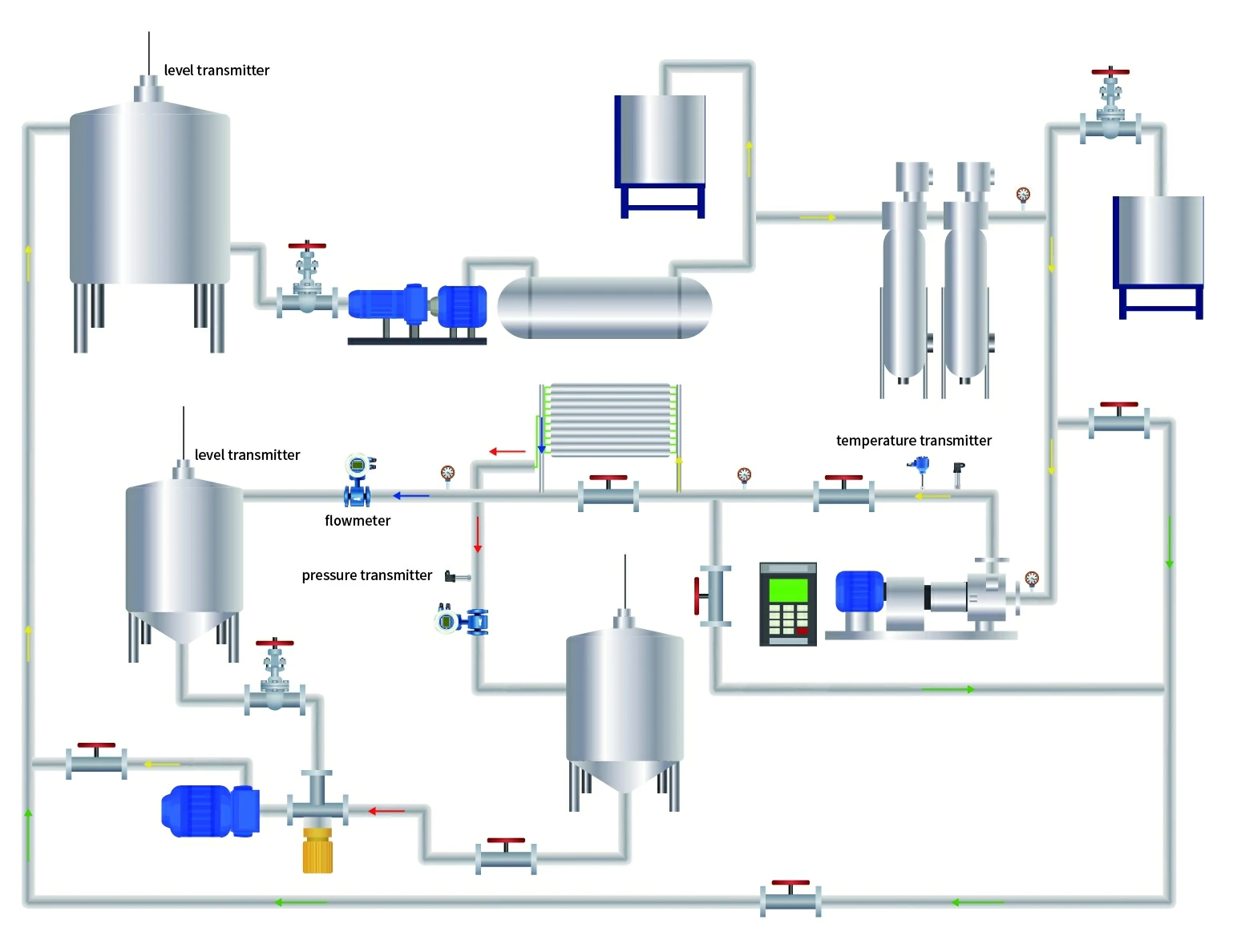

Flowmeter, IoT, Natural gas industry, Electricity industry, Petroleum and chemical industry

Leave a MessageMPM3801A digital pressure transmitter is a pressure transducer with a digital output product suitable for the general industry. The general-purpose structure of this product can cover more industrial application scenarios. The internal sensor and base of MPM3801A are assembled structures, and the measuring range can reach 100MPa.

There are two types of MPM3801A, Type I and Type II. Type I has slightly larger dimensions and is suitable for industries such as mechanical equipment matching and hydraulic systems. Type II is a component type, and its structure has a standard thread of M20 or M27 at the outlet end. This thread can be installed in the equipment or gauge heads. Therefore, Type II products can be applied to secondary instruments, IoT terminals, etc.

Feature

• I²C digital air pressure sensor

• Low power consumption

• Accuracy: ±0.25%FS

• General industrial application

Specification

• Range: 0mbar~1000bar

• Overpressure: ≤2 times FS or 1100 bar (minimum value is valid)

• Pressure Type: gauge, absolute, sealed gauge

• Pressure Accuracy: ±1%FS, ±0.5%FS, ±0.25%FS

• Temperature Accuracy: ±1.5℃ (tested in constant temperature for reference)

• Long-term Stability: ±0.2%FS/year

• Compensated Temperature: -10℃ ~ 50℃

• Application Temperature: -20℃ ~ 80℃

• Storage Temperature: -20℃ ~ 85℃

Image:

MPM3801A digital pressure transmitter is a pressure transducer with a digital output product suitable for the general industry. The general-purpose structure of this product can cover more industrial application scenarios. The internal sensor and base of MPM3801A are assembled structures, and the measuring range can reach 100MPa.

There are two types of MPM3801A, Type I and Type II. Type I has slightly larger dimensions and is suitable for industries such as mechanical equipment matching and hydraulic systems. Type II is a component type, and its structure has a standard thread of M20 or M27 at the outlet end. This thread can be installed in the equipment or gauge heads. Therefore, Type II products can be applied to secondary instruments, IoT terminals, etc.

Feature

• I²C digital air pressure sensor

• Low power consumption

• Accuracy: ±0.25%FS

• General industrial application

Specification

• Range: 0mbar~1000bar

• Overpressure: ≤2 times FS or 1100 bar (minimum value is valid)

• Pressure Type: gauge, absolute, sealed gauge

• Pressure Accuracy: ±1%FS, ±0.5%FS, ±0.25%FS

• Temperature Accuracy: ±1.5℃ (tested in constant temperature for reference)

• Long-term Stability: ±0.2%FS/year

• Compensated Temperature: -10℃ ~ 50℃

• Application Temperature: -20℃ ~ 80℃

• Storage Temperature: -20℃ ~ 85℃

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

I²C or SPI protocol

Low power consumption: standby power consumption ≤ 5μA, average working current ≤ 2.5mA

Low-voltage power supply: 3.3V, 5V, battery-powered

Secondary temperature compensation, total accuracy up to ±0.25%FS

RoHS and Reach approved

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...

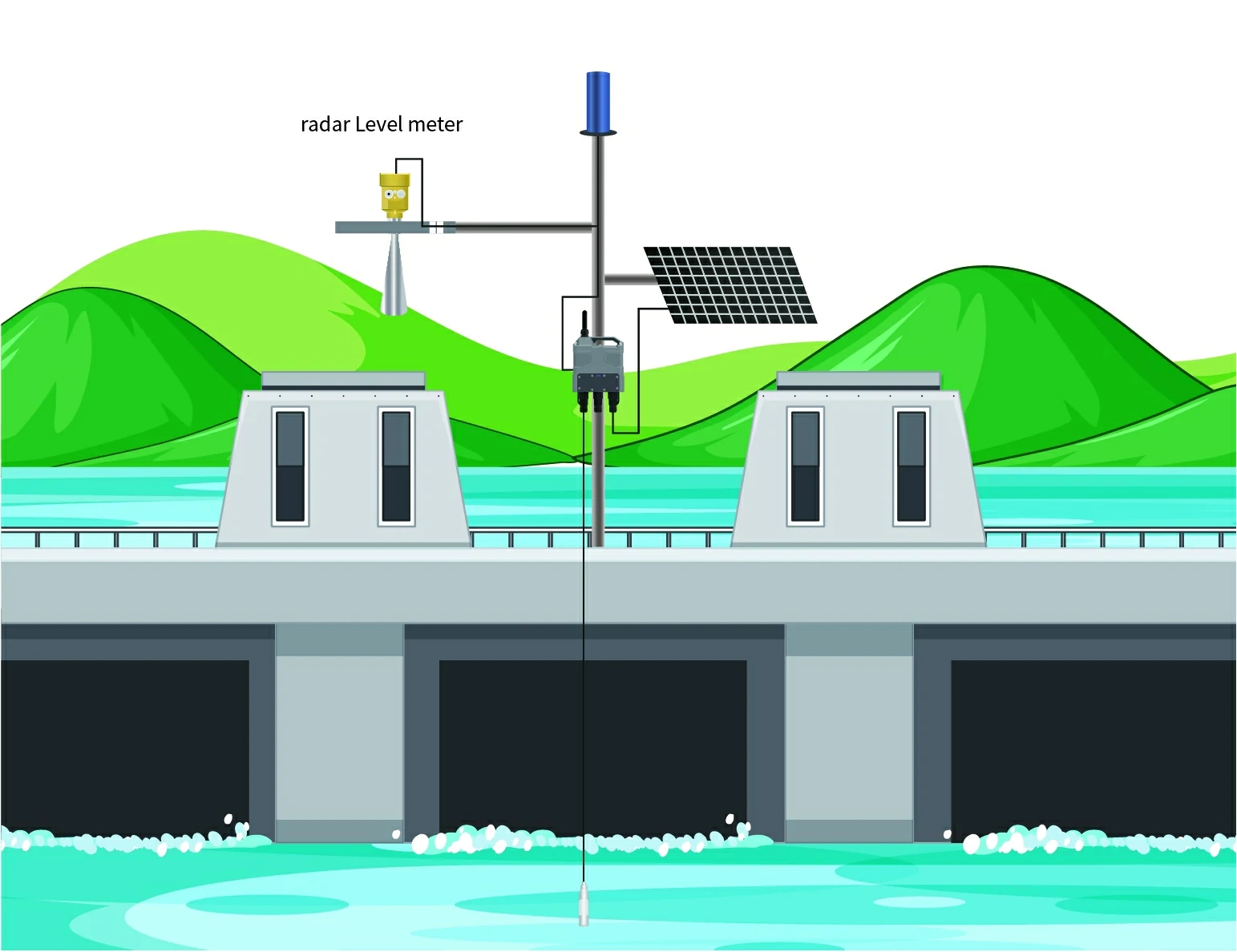

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...

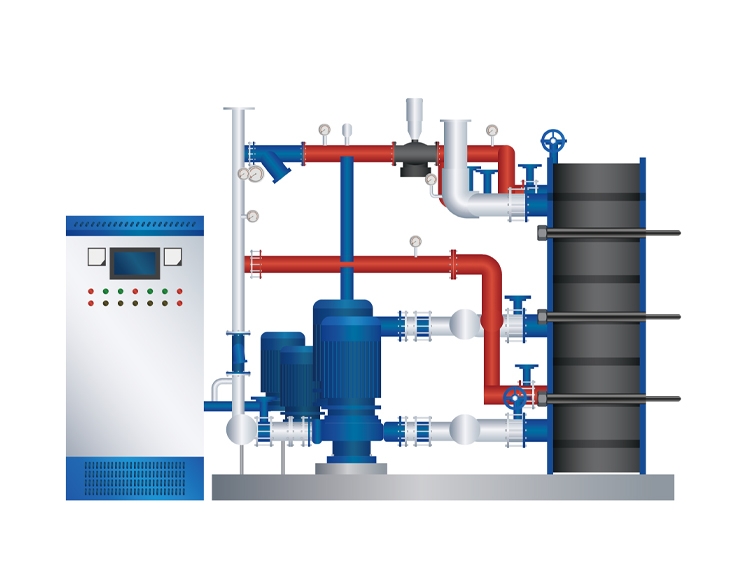

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...