Piezoresistive Pressure Transducer

Range:-1bar...0~0.2bar…1000bar

Accuracy: ±0.25%FS (Typ.)

Power Supply: 1.5mADC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM3801GRF

Used For

Process Industry Control, Gas Flowmeter Industry, Intelligent Pressure Instrument, Medical Equipment, IoT

Leave a MessageThe MPM3801GRF digital pressure transmitter uses the MPM3801 stainless steel oil-filled transducer as the sensing element. The all stainless steel construction provides excellent corrosion resistance and long-term stability. The pressure range is 0 mbar ~ 70 mbar.... ...70 bar, with outputs in standard I²C or SPI protocol. Low power consumption and fully temperature compensated to ensure good stability over the operating temperature range.

The MPM3801GRF is an IIC digital pressure transmitter for volume corrector applications such as gas pressure monitoring, volume corrector gas flow meters, Roots flow meters, turbine flow meters, solenoid water meters, etc. The MPM3801GRF is a digital pressure transmitter for volume corrector applications.

Features

• Standard I²C or SPI protocols

• Suitable for gas roots flowmeter, waistwheel flowmeter

• RoHS approved

Specifications

• Range: 0mbar ~ 70mbar/200mbar/350mbar/700mbar/1bar/2bar/3.5bar/5bar/7bar/10bar/16bar/20bar/35bar/70bar

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute, sealed gauge

Image:

The MPM3801GRF digital pressure transmitter uses the MPM3801 stainless steel oil-filled transducer as the sensing element. The all stainless steel construction provides excellent corrosion resistance and long-term stability. The pressure range is 0 mbar ~ 70 mbar.... ...70 bar, with outputs in standard I²C or SPI protocol. Low power consumption and fully temperature compensated to ensure good stability over the operating temperature range.

The MPM3801GRF is an IIC digital pressure transmitter for volume corrector applications such as gas pressure monitoring, volume corrector gas flow meters, Roots flow meters, turbine flow meters, solenoid water meters, etc. The MPM3801GRF is a digital pressure transmitter for volume corrector applications.

Features

• Standard I²C or SPI protocols

• Suitable for gas roots flowmeter, waistwheel flowmeter

• RoHS approved

Specifications

• Range: 0mbar ~ 70mbar/200mbar/350mbar/700mbar/1bar/2bar/3.5bar/5bar/7bar/10bar/16bar/20bar/35bar/70bar

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute, sealed gauge

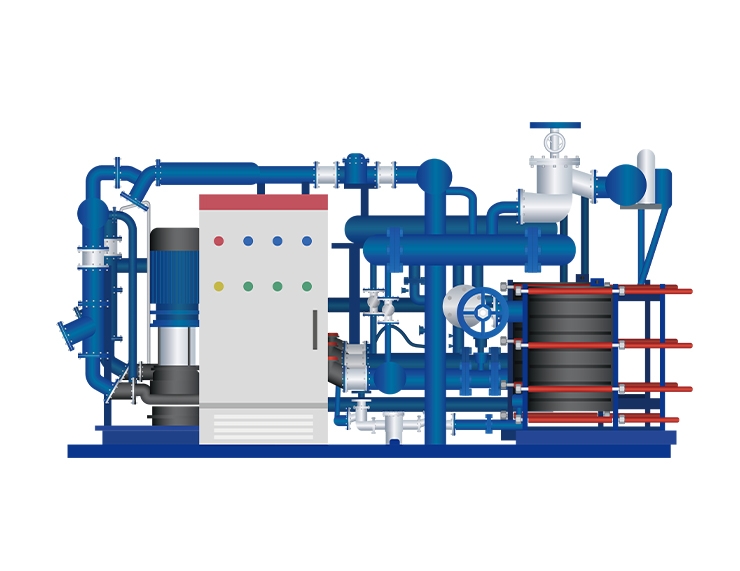

Pressure transmitters, temperature tranmitters and electromagnetic flowmeters are installed in the marine water circulation cooling system to ensure the heat exchange efficiency of the central cooler. By optimizing seawater flow control, energy saving effects are maximized and stable operation of the cooling system is ensured.

more info...

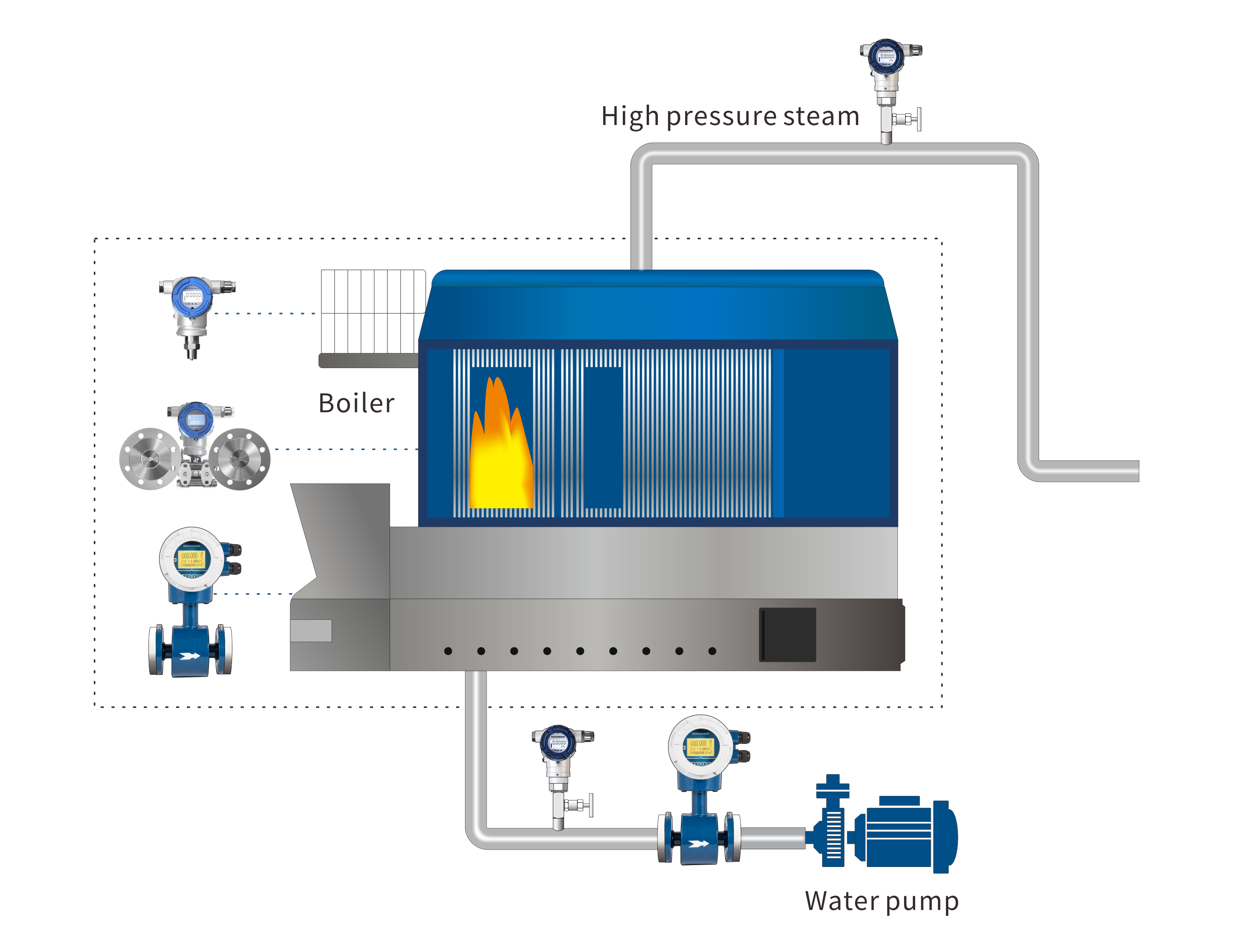

In the electric power industry, especially in power plants and transmission systems, it is very important to accurately monitor and control pressure, level, temperature and flow, because these specifications will directly affect the operating efficiency and safety of the system. Micro Sensor's monitoring instrumentation solutions integrate advanced sensor technology and intelligent control systems, which can provide accurate data and efficient control even in complex environments, and optimize the power production and transmission process.

more info...

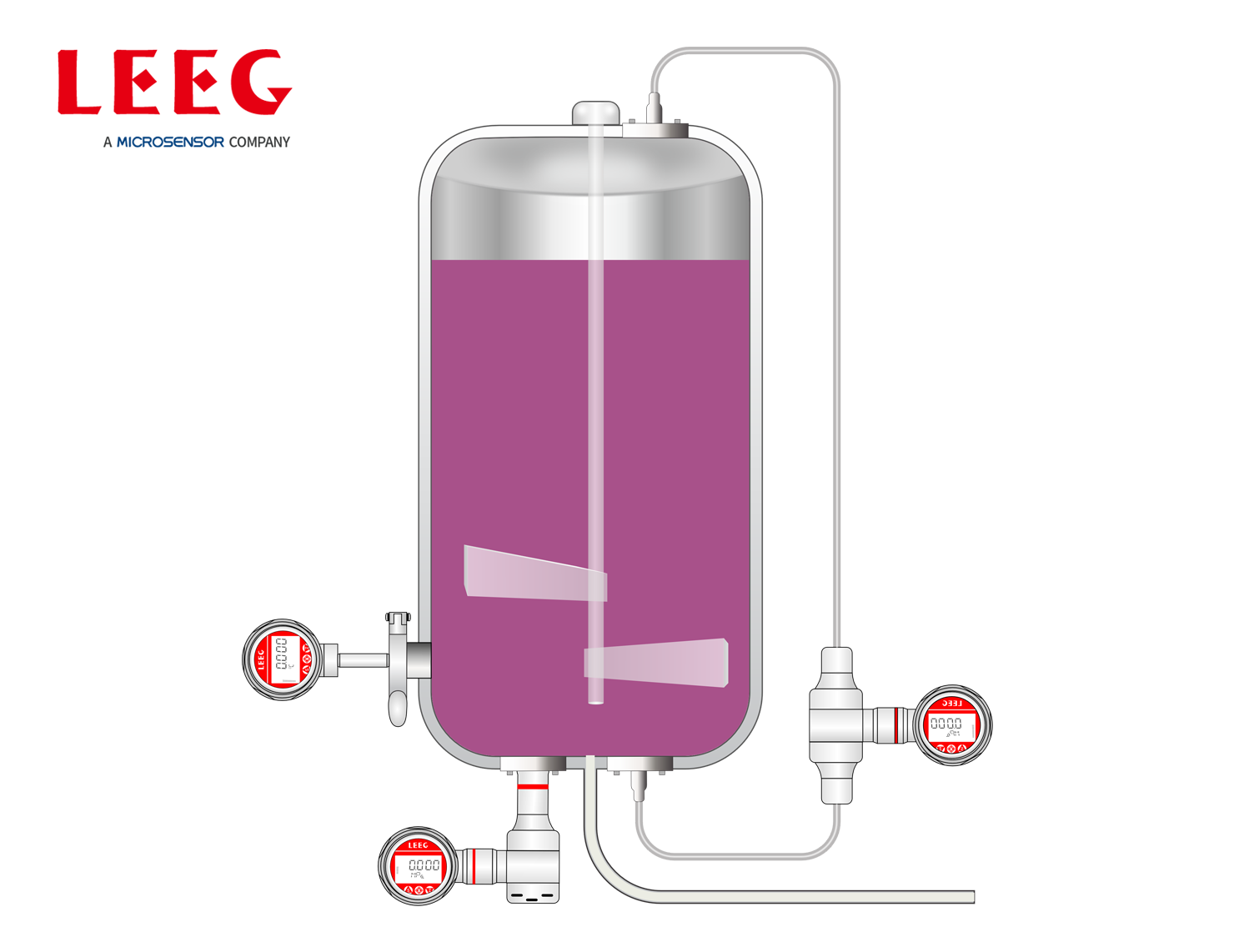

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...