Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM380

Used For

Food, Medicine, Sanitation Fields

Leave a MessageMPM380 piezoresistive pressure transducer is a general-purpose gas and liquid medium measurement pressure sensor. Using silicon piezoresistive pressure sensitive elements, MPM380 has stable performance and high precision. The stainless steel shell has good compatibility with the interface medium. The pressure port is M20×1.5 external thread, and the end face of the gasket is sealed. MPM380 piezoresistive pressure sensor is suitable for pressure measurement of various dynamic and static gas and liquid media. MPM380 is also available with flush diaphragm type, G1/2 external thread pressure port and Viton gasket. The dynamic pressure transducer is more suitable for occasions where the measurement medium may be fouled, such as food, medicine, hygiene and other industries. According to the needs of actual application scenarios, MicroSensor provides you with a variety of customized products.

Features

• Solid state piezoresistive pressure sensor, high reliability and stability

• All stainless steel construction

• Standard thread pressure measurement method

• Cable or connector lead way

Image:

MPM380 piezoresistive pressure transducer is a general-purpose gas and liquid medium measurement pressure sensor. Using silicon piezoresistive pressure sensitive elements, MPM380 has stable performance and high precision. The stainless steel shell has good compatibility with the interface medium. The pressure port is M20×1.5 external thread, and the end face of the gasket is sealed. MPM380 piezoresistive pressure sensor is suitable for pressure measurement of various dynamic and static gas and liquid media. MPM380 is also available with flush diaphragm type, G1/2 external thread pressure port and Viton gasket. The dynamic pressure transducer is more suitable for occasions where the measurement medium may be fouled, such as food, medicine, hygiene and other industries. According to the needs of actual application scenarios, MicroSensor provides you with a variety of customized products.

Features

• Solid state piezoresistive pressure sensor, high reliability and stability

• All stainless steel construction

• Standard thread pressure measurement method

• Cable or connector lead way

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

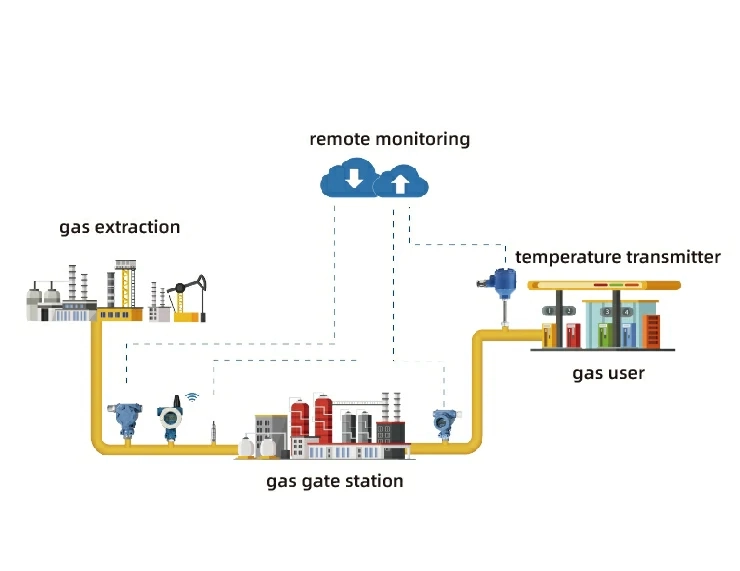

Natural gas undergoes a long process of transportation pipeline transmission, filtration, odorization, and pressure regulation from extraction to end-user consumption. In this process, monitoring the pressure and temperature within the pipeline is critical to ensuring the proper operation of the system.

more info...

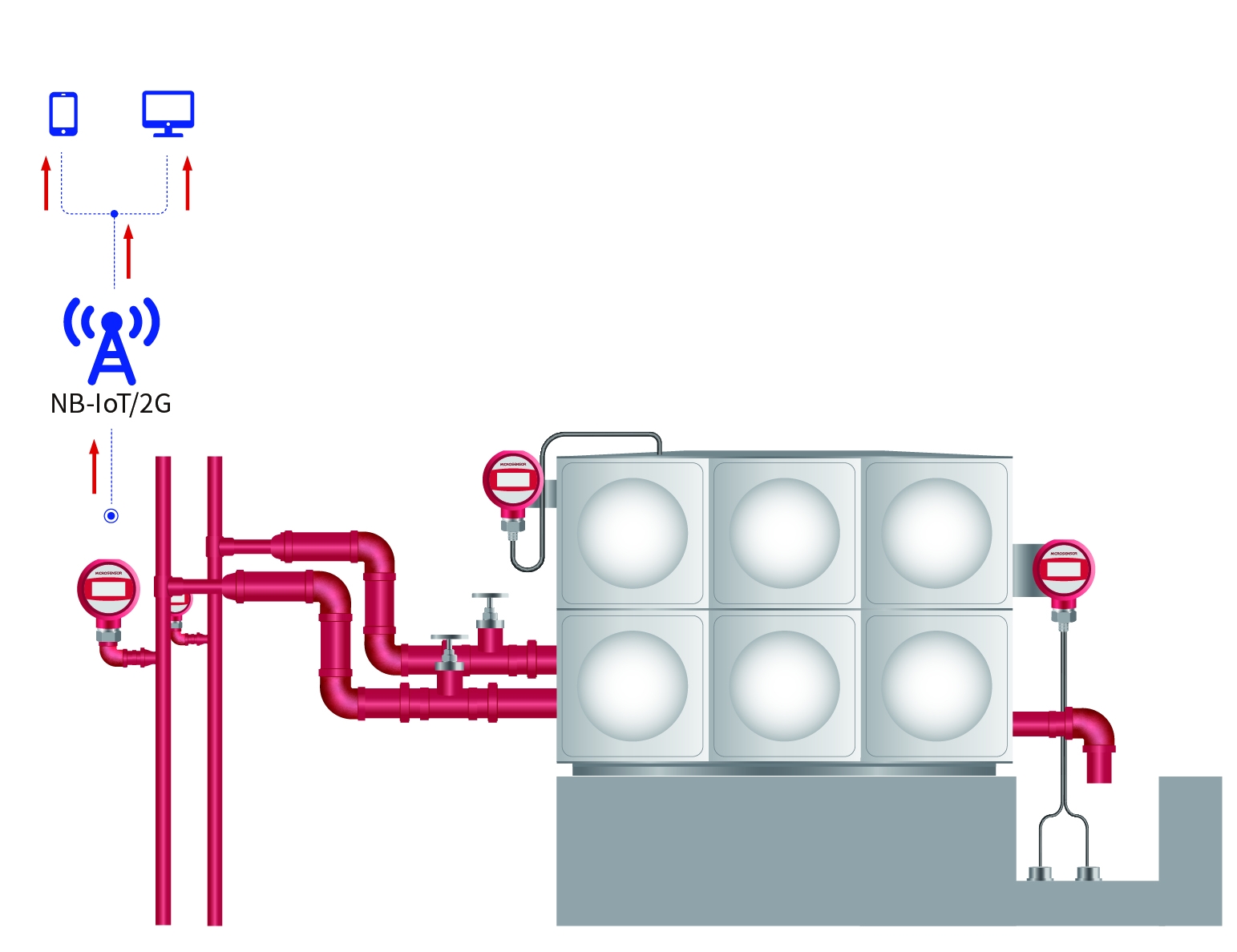

The normal operation of fire-fighting water pipeline plays an important role in safeguarding citizens' personal and property safety. Monitoring instruments are installed at each monitoring point of the fire protection pipeline to monitor pressure and level data in real time, so that when an error occurs, faults are located in time and alarms are given to facilitate staff maintenance and processing.

more info...

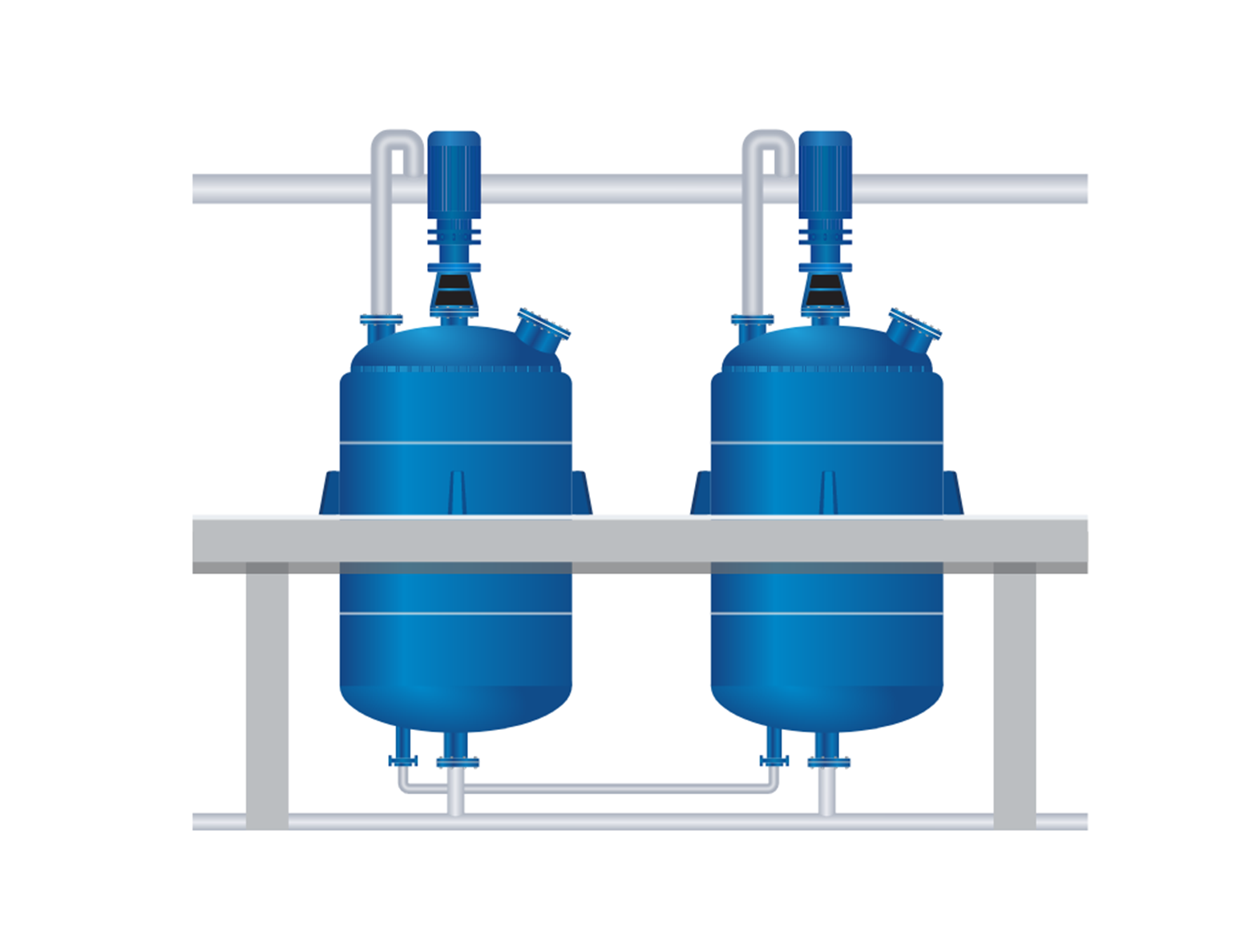

During machine downtime or product changes, the press rolls are cleaned and coated with a specialist solution to protect against adhesions and deposits, hence avoiding paper difficulties. The 50°C coating mixture is pushed through the machine. To maintain automated functioning, the tank's level and filter status must be continuously monitored.

more info...

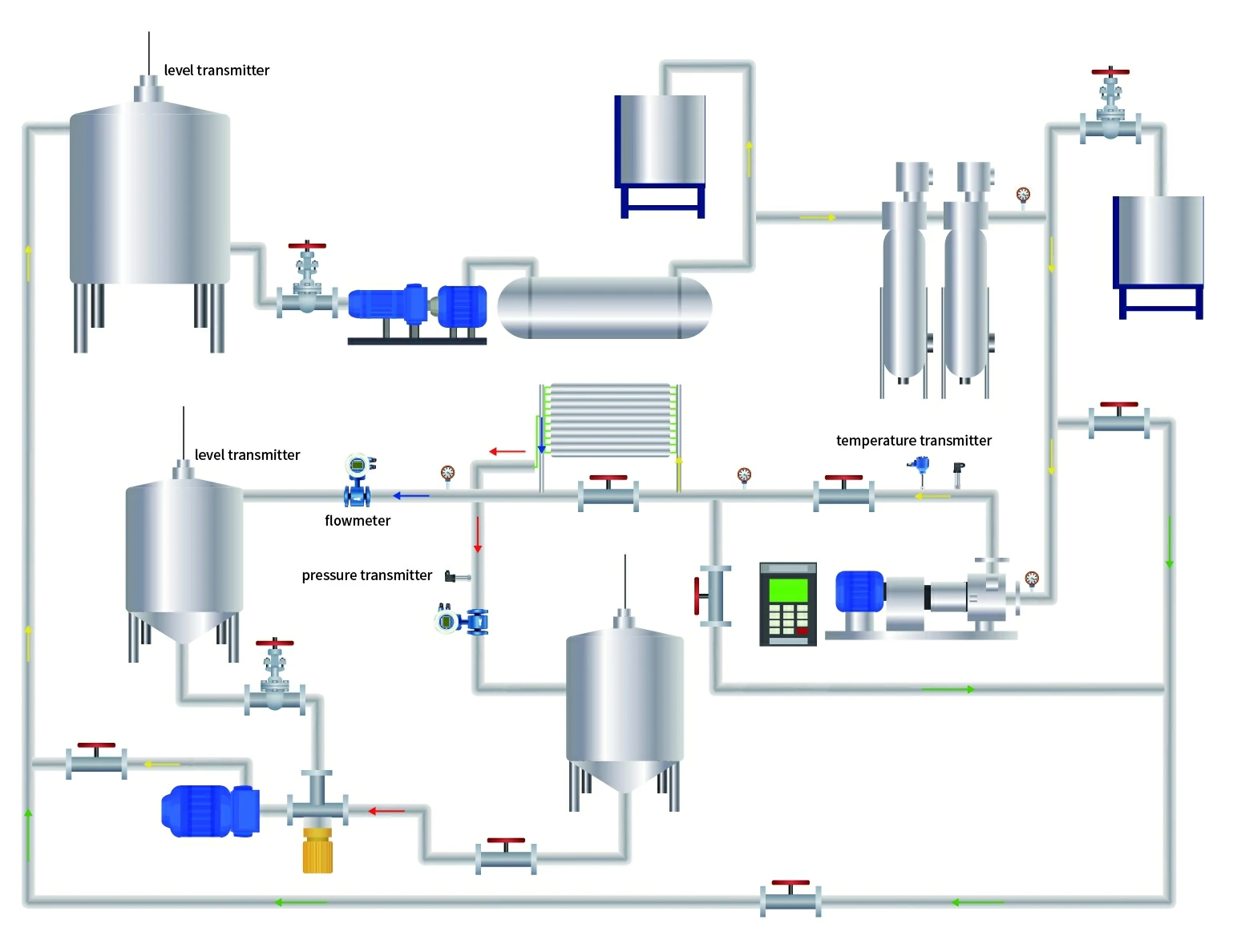

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...