Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

MPM4841B

Used For

Mechanical Manufacturing, Petroleum and Petrochemical Industry, Measurement and Control Technology, Hydraulic Pressure and Pneumatic Field, Energy and Water Treatment

Leave a MessageMPM4841B Economical Pressure Transmitter adopts stable and reliable piezoresistive pressure sensor. It has a unique conditioning circuit that produces a standard current or voltage signal. The compact design of this pressure transducer is CE and RoHS certified for stable and reliable performance. The 0-10v pressure transducer offers a wide range of output signals to meet the needs of different customers and is ideal for a variety of industrial applications. Moreover, it offers excellent quality at extremely competitive pricing.

Specifications

• Range:

A Type: 0bar ~ 0.35bar…200bar

B Type: 0bar ~ 250bar…600bar

• Overpressure: ≤2 times FS

• Pressure Type: Gauge, absolute, sealed gauge

• Long-term Stability : ±0.3%FS/year

• Operation Temperature:

-30℃ ~ 80℃ (B1 type , B4 type)

-20℃ ~ 70℃ (B2 type, cable material: PE, PVC)

Image:

MPM4841B Economical Pressure Transmitter adopts stable and reliable piezoresistive pressure sensor. It has a unique conditioning circuit that produces a standard current or voltage signal. The compact design of this pressure transducer is CE and RoHS certified for stable and reliable performance. The 0-10v pressure transducer offers a wide range of output signals to meet the needs of different customers and is ideal for a variety of industrial applications. Moreover, it offers excellent quality at extremely competitive pricing.

Specifications

• Range:

A Type: 0bar ~ 0.35bar…200bar

B Type: 0bar ~ 250bar…600bar

• Overpressure: ≤2 times FS

• Pressure Type: Gauge, absolute, sealed gauge

• Long-term Stability : ±0.3%FS/year

• Operation Temperature:

-30℃ ~ 80℃ (B1 type , B4 type)

-20℃ ~ 70℃ (B2 type, cable material: PE, PVC)

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

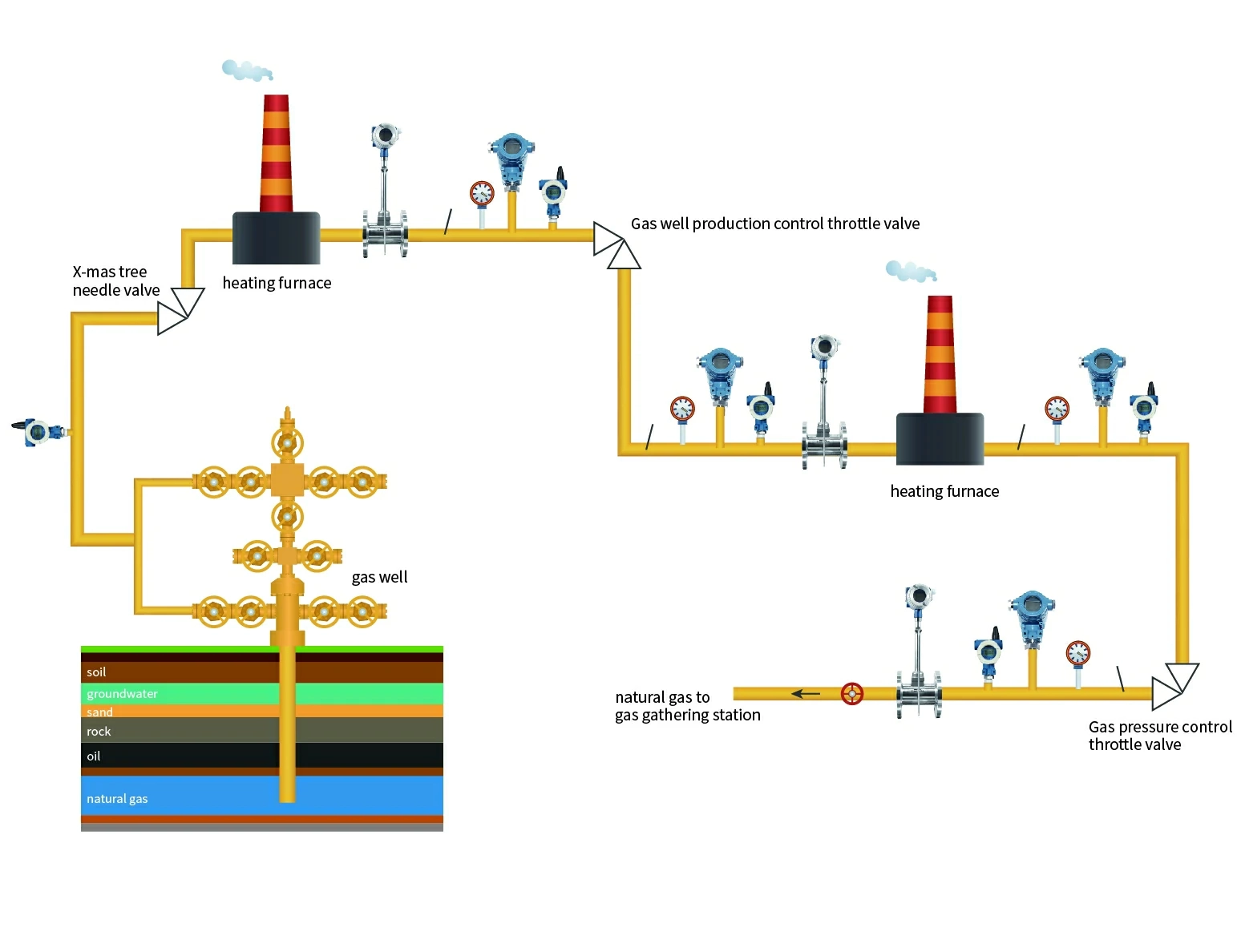

Centralizing the oil and gas produced by scattered oil wells, processing and initial processing, and exporting it after meeting the standards. The process requires multiple steps, including oil and gas separation, crude oil dehydration, and natural gas purification, thus requiring various instruments to measure production parameters.

more info...

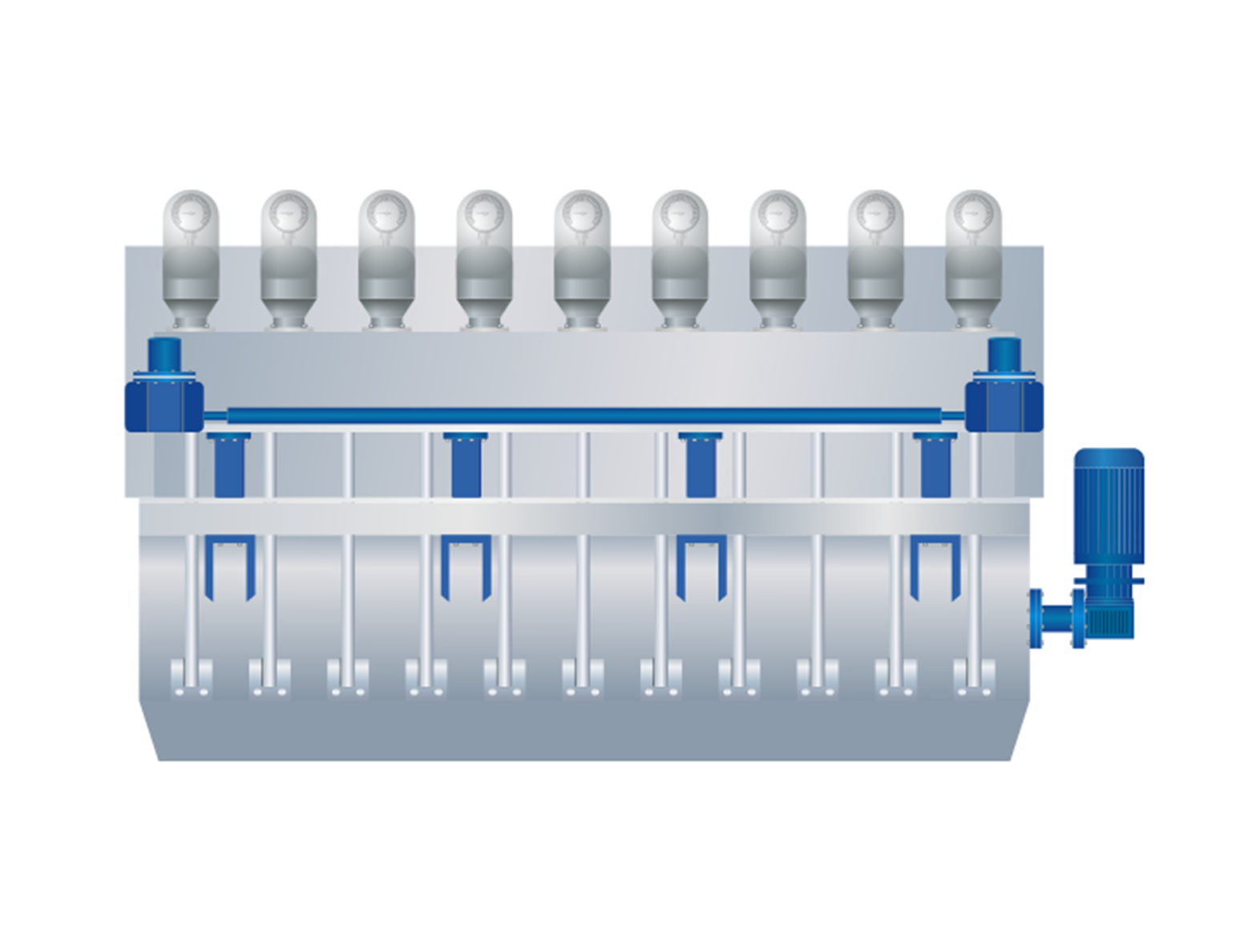

In the papermaking process, pulp is fed into the headbox of the paper machine. In the hydraulic headbox, pulp enters the weir pool via the conical distribution pipe and tube bundles, and is then sprayed onto the forming wire by the weir plate. Since the pulp jet velocity is controlled by adjusting the headbox slice pressure per the wire speed, accurate pressure measurement in the headbox is essential.

more info...

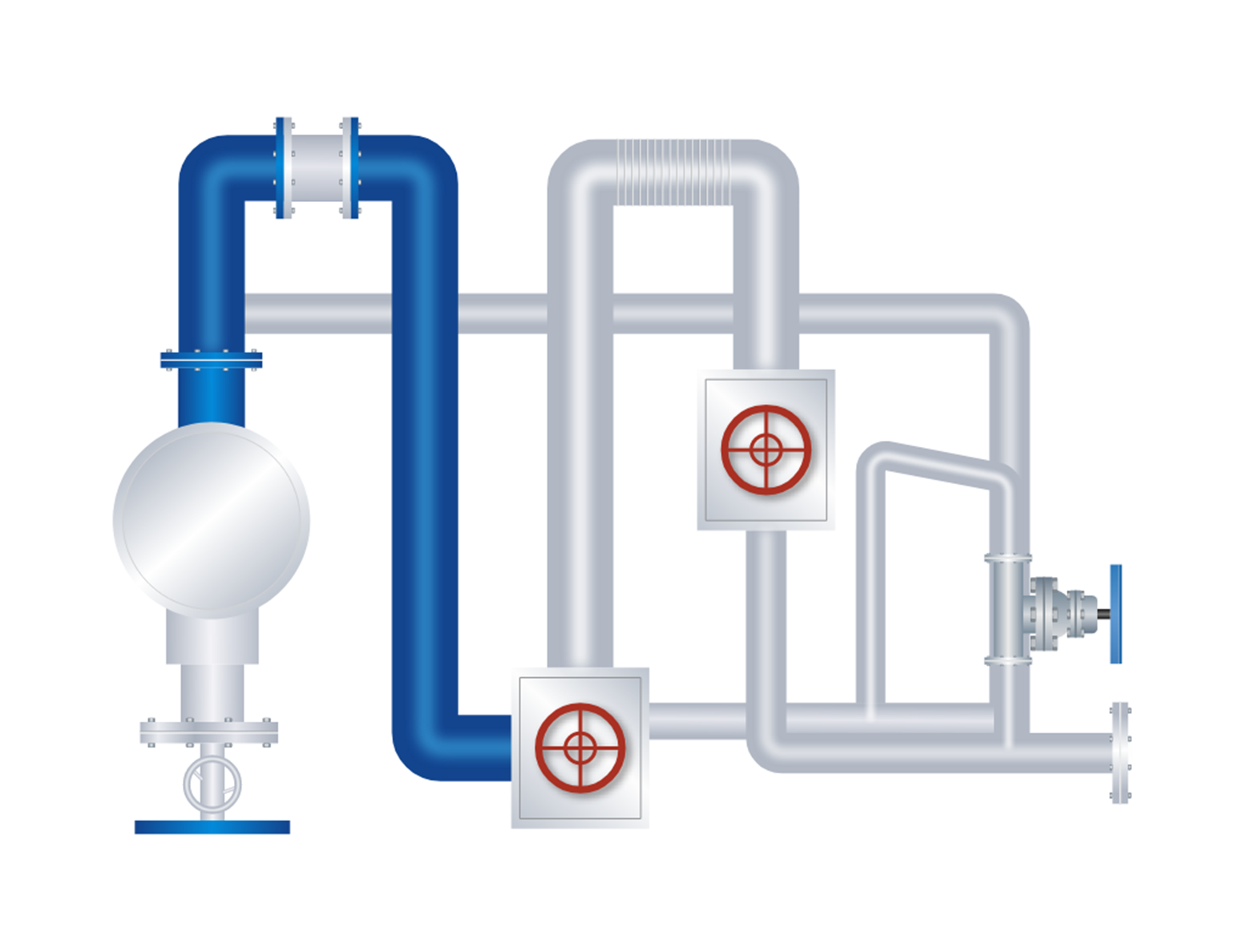

The paper machine's drying section employs steam-heated cylinders, with steam generated by a separate boiler and transported by pipelines. To ensure optimal steam supply, a differential pressure transmitter with an orifice plate is used to measure flow, allowing for accurate planning.

more info...

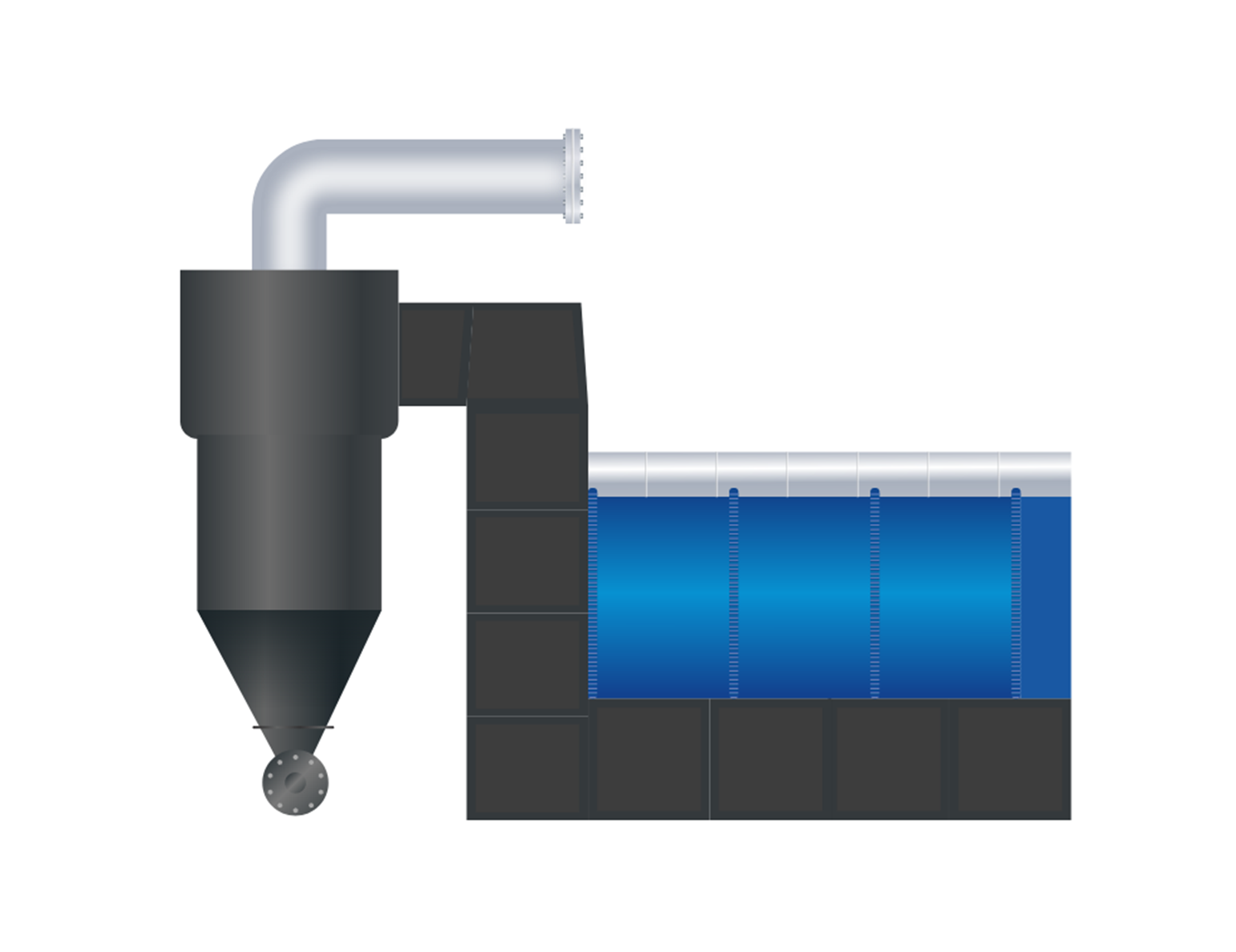

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...