Differential Pressure Transmitter

0bar~0.4bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4841A

Used For

Mechanical Manufacturing, Petroleum and Petrochemical Industry, Hydraulic Pressure and Pneumatic Field, Energy and Water Treatment

Leave a MessageMPM4841A pressure transmitter designed for general industrial applications stands out not only due to its compact design but also its exceptional quality, all offered at remarkably competitive prices. The piezoresistive pressure-sensitive element cooperates with a unique conditioning circuit to provide a variety of output signals to meet the needs of different customers. The high-cost performance of the product is very suitable for general industry use. With CE, RoHS certificated, the pressure transmitter is suitable for hydraulic pressure and pneumatic field, energy and water treatment, etc.

Feature

• Compact Structure

• Economically applicable

• Output Signals Optional

• CE, RoHS Certified

Image:

MPM4841A pressure transmitter designed for general industrial applications stands out not only due to its compact design but also its exceptional quality, all offered at remarkably competitive prices. The piezoresistive pressure-sensitive element cooperates with a unique conditioning circuit to provide a variety of output signals to meet the needs of different customers. The high-cost performance of the product is very suitable for general industry use. With CE, RoHS certificated, the pressure transmitter is suitable for hydraulic pressure and pneumatic field, energy and water treatment, etc.

Feature

• Compact Structure

• Economically applicable

• Output Signals Optional

• CE, RoHS Certified

0bar~0.4bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

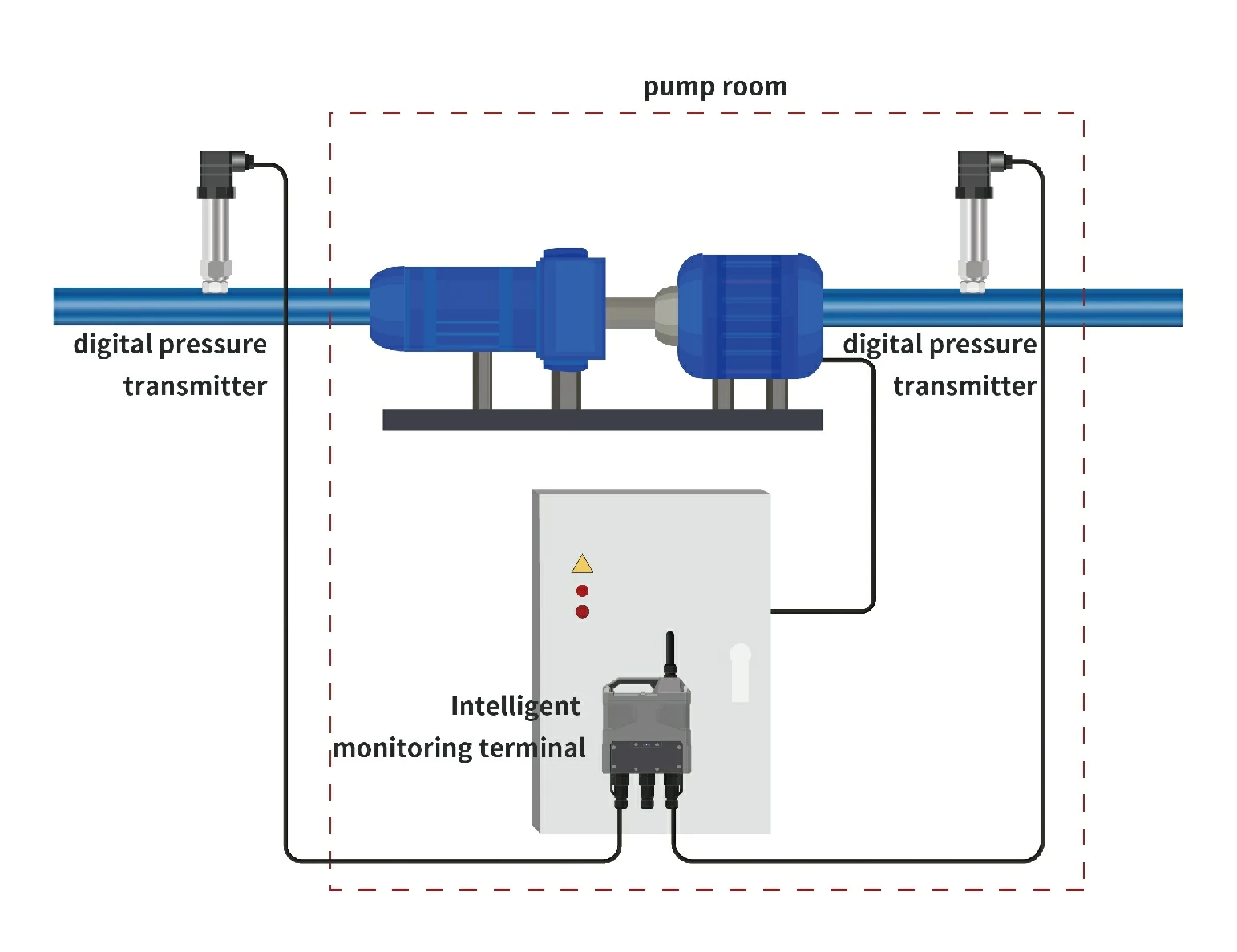

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

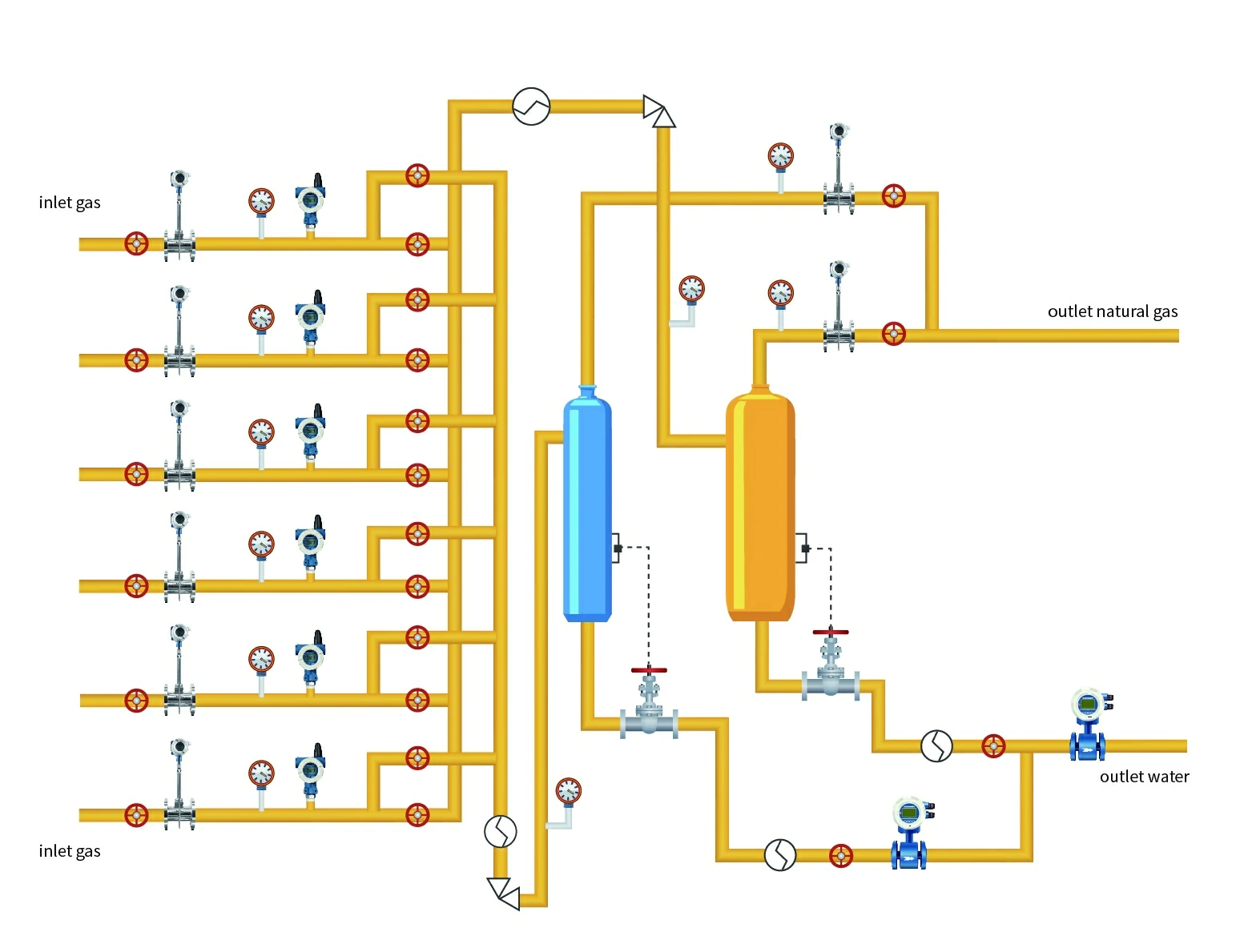

Gas gathering stations gather and process natural gas from multiple wells. Instruments in the pipeline monitor real-time data changes, such as gas or liquid flow. It helps control the water injection for the purpose of measuring and transporting oil and gas.

more info...

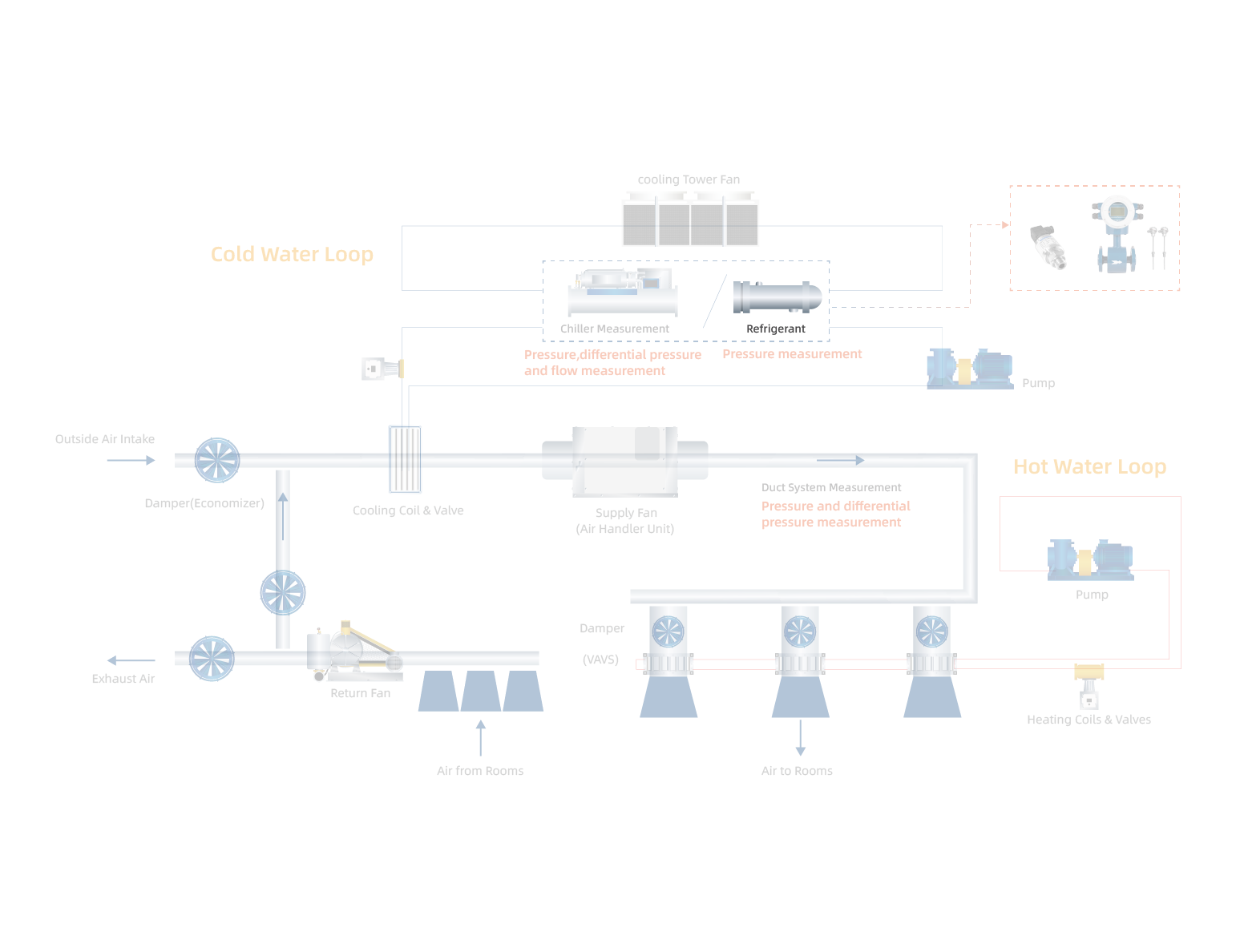

In HVAC systems, measuring the pressure of refrigerants is critical. Pressure transmitters monitor the refrigerant's pressure to ensure it operates within safe limits, preventing leaks and system failures. Accurate pressure measurement enhances system efficiency, ensures optimal cooling performance, and maintains safety by detecting potential issues early

more info...

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...