Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM426W Series

Used For

Fuel storage tanks like gasoline, diesel, kerosene. Chemical storage tanks like methanol, ethanol, lubricating oil, diesel exhaust fluid.

Leave a MessageMPM426W SERIES submersible level transmitter is designed for Fuel and Chemicals Measurement. MPM426W Series is a stable, accurate, real-time monitoring liquid level, pressure and temperature in storage tank multi-parameter measurement throw-in type liquid level meter. The measurement of fuels and chemicals requires the level meter to be resistant to aggressive media. The fully welded structure of the MPM426W Series ensures super tightness and medium compatibility.

MPM426W Series includes two models, MPM426WPC and MPM426WPF. MPM426WPC is mostly used in chemical liquid level monitoring scenarios. MPM426WPF is more suitable for fuel or oil level monitoring. These two products can also be widely used in applications requiring high corrosion resistance, explosion-proof performance, and protection performance, such as petroleum and petrochemical, vehicles, mining, and chemical industries. This fuel pressure transmitter provides an effective solution for tank level monitoring, control and overflow protection.

Features

• Special for fuel and chemicals measuring

• Support pressure, liquid level, temperature measurement

• Various output formats are optional

• Low power consumption, low maintenance cost

• CSA, IECEX, ATEX international explosion-proof certification

Image:

MPM426W SERIES submersible level transmitter is designed for Fuel and Chemicals Measurement. MPM426W Series is a stable, accurate, real-time monitoring liquid level, pressure and temperature in storage tank multi-parameter measurement throw-in type liquid level meter. The measurement of fuels and chemicals requires the level meter to be resistant to aggressive media. The fully welded structure of the MPM426W Series ensures super tightness and medium compatibility.

MPM426W Series includes two models, MPM426WPC and MPM426WPF. MPM426WPC is mostly used in chemical liquid level monitoring scenarios. MPM426WPF is more suitable for fuel or oil level monitoring. These two products can also be widely used in applications requiring high corrosion resistance, explosion-proof performance, and protection performance, such as petroleum and petrochemical, vehicles, mining, and chemical industries. This fuel pressure transmitter provides an effective solution for tank level monitoring, control and overflow protection.

Features

• Special for fuel and chemicals measuring

• Support pressure, liquid level, temperature measurement

• Various output formats are optional

• Low power consumption, low maintenance cost

• CSA, IECEX, ATEX international explosion-proof certification

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

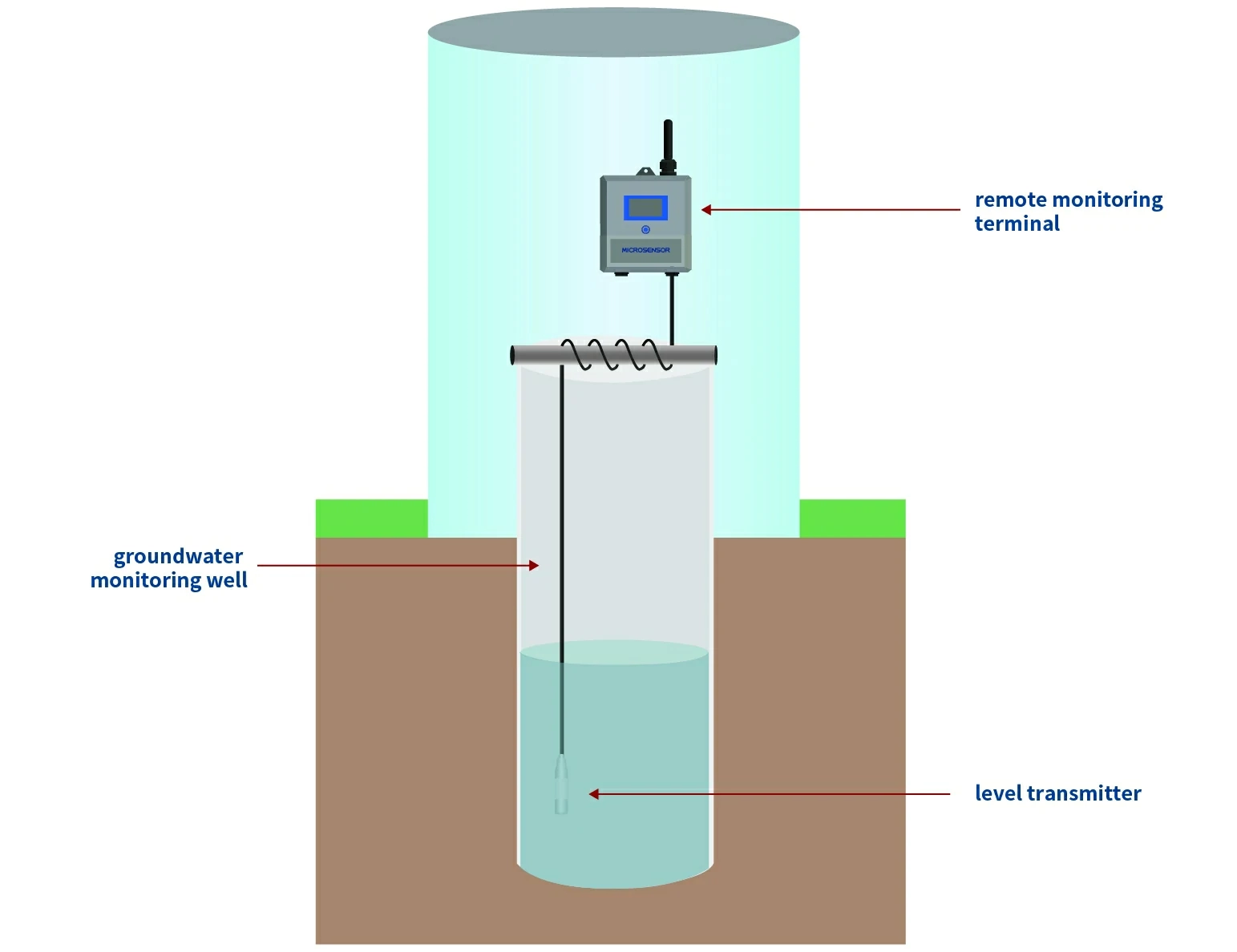

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

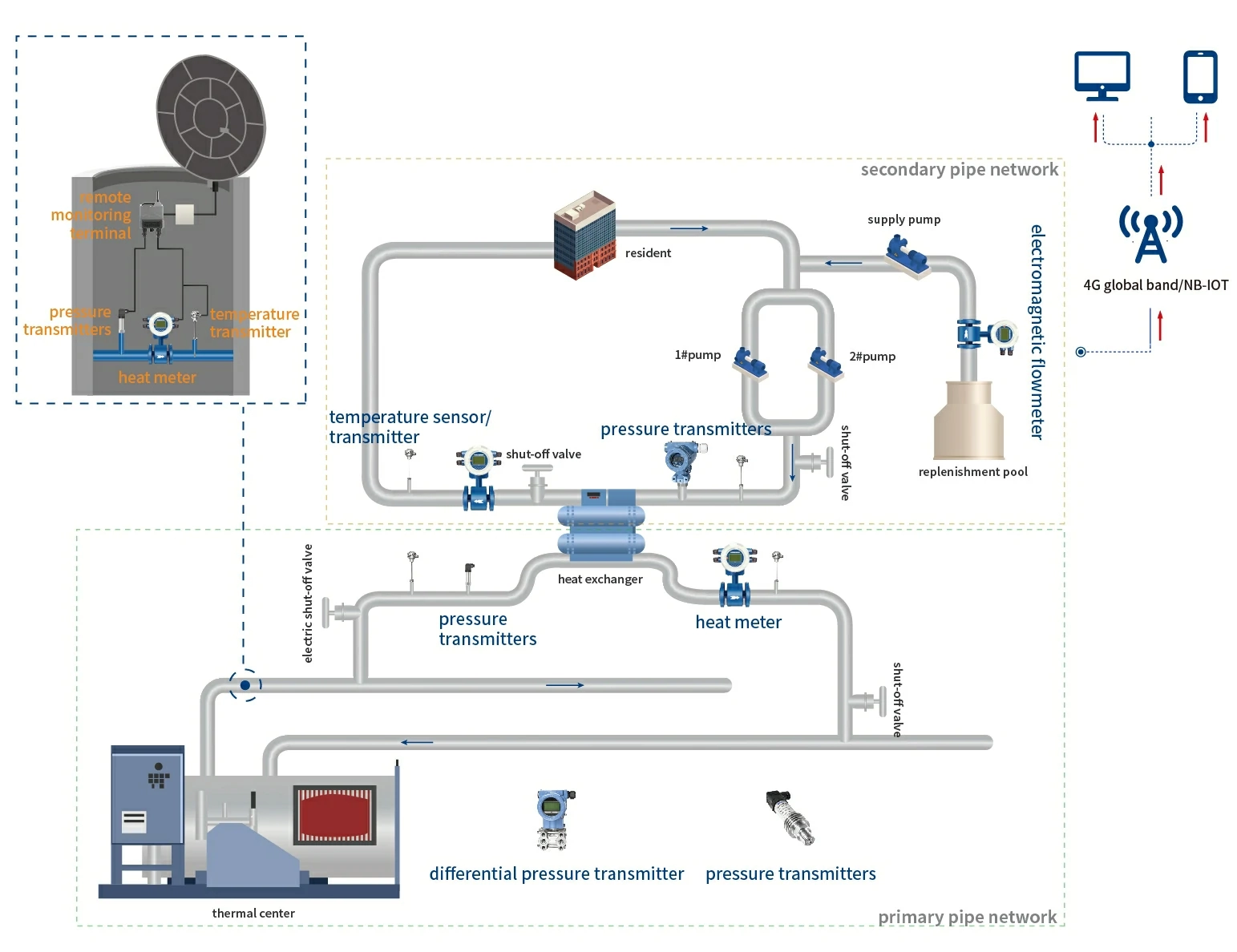

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...

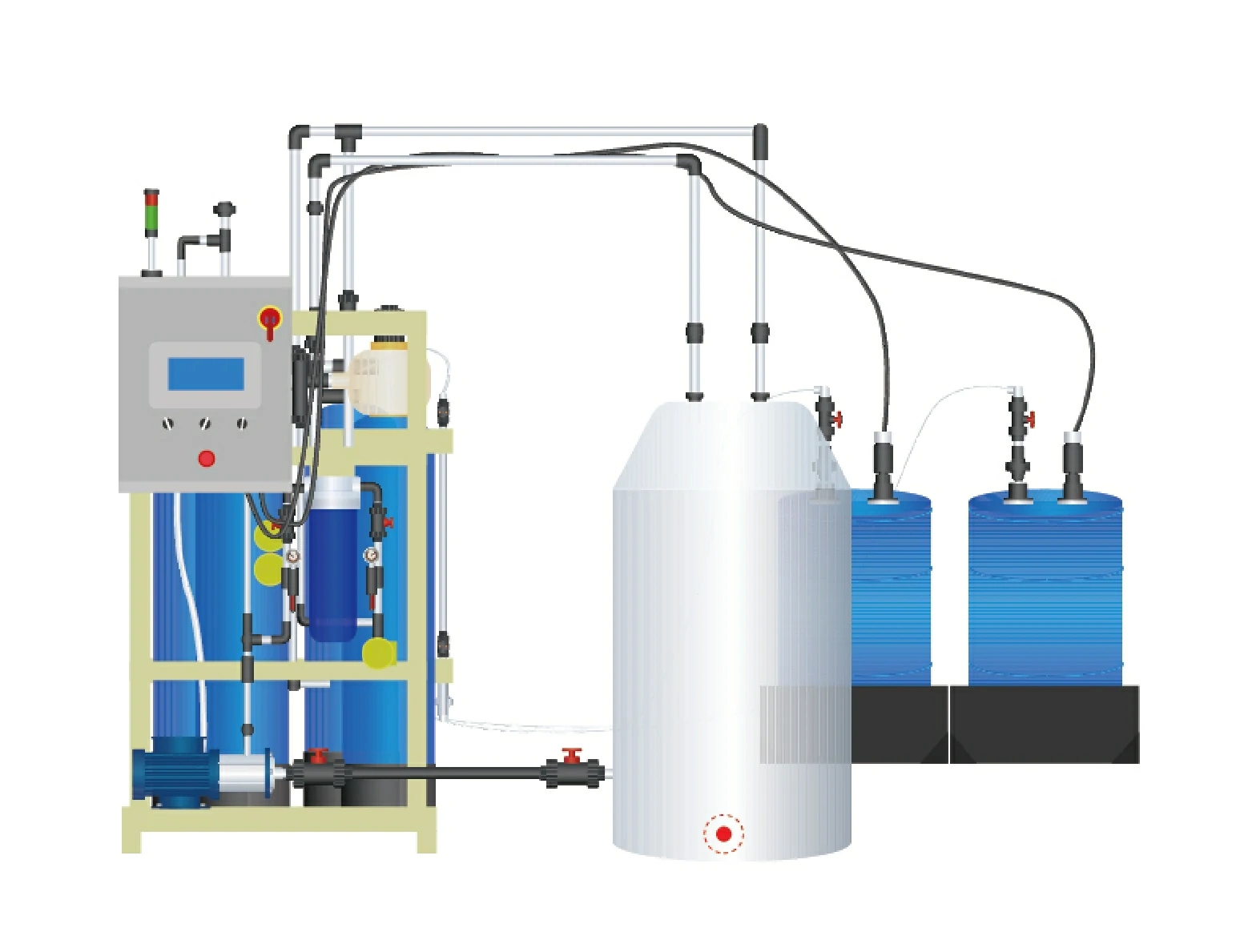

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...

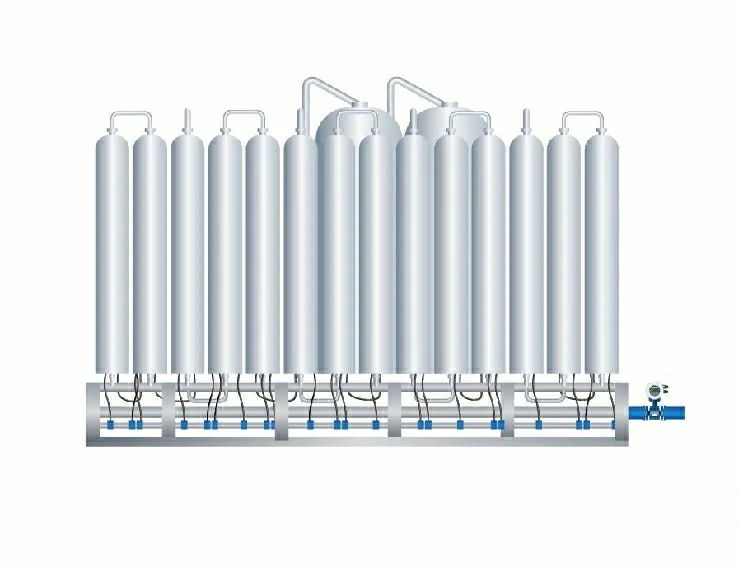

Deionized water is commonly used in industrial manufacturing cleaning processes. The target pressure values should be achieved during the production. It is necessary to monitor the pressure of the inlet and outlet. Only no blockages or leaks ensure normal operation of the production process.

more info...