Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM416WRK

Used For

Petroleum, Chemical, Water Treatment

Leave a MessageMPM416WRK is flexible armoured protection tube submersible level transmitter. It adopts high-performance piezoresistive pressure sensor and fully sealed stainless steel structure, equipped with aluminium alloy electric junction box, which is very convenient for installation, wiring and calibration. It can accurately measure the static pressure of liquid proportional to the depth of the liquid, and convert the pressure signal into a standard current or voltage output signal through the built-in amplifying circuit board. In addition, it features high accuracy, small size and easy operation. The transmitter is explosion-proof certified and can work in harsh environments and hazardous areas.

Features

• Liquid static pressure measurement

• Fully sealed stainless steel structure

• CE & Explosion-proof certificate

Specifications

• Pressure range: 1, 2, 5, 10, 20mH2O

• Overpressure: 1.5times FS

• Accuracy: +0.25%FS(typ.) +0.5%FS(max.)

• Stability error: +0.1%FS(typ.) +0.2%FS(max.) pressure range>10mH2O+10mmH2O(typ.) +20mmH2O(max.) pressure range≤10mH2O

Image:

MPM416WRK is flexible armoured protection tube submersible level transmitter. It adopts high-performance piezoresistive pressure sensor and fully sealed stainless steel structure, equipped with aluminium alloy electric junction box, which is very convenient for installation, wiring and calibration. It can accurately measure the static pressure of liquid proportional to the depth of the liquid, and convert the pressure signal into a standard current or voltage output signal through the built-in amplifying circuit board. In addition, it features high accuracy, small size and easy operation. The transmitter is explosion-proof certified and can work in harsh environments and hazardous areas.

Features

• Liquid static pressure measurement

• Fully sealed stainless steel structure

• CE & Explosion-proof certificate

Specifications

• Pressure range: 1, 2, 5, 10, 20mH2O

• Overpressure: 1.5times FS

• Accuracy: +0.25%FS(typ.) +0.5%FS(max.)

• Stability error: +0.1%FS(typ.) +0.2%FS(max.) pressure range>10mH2O+10mmH2O(typ.) +20mmH2O(max.) pressure range≤10mH2O

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

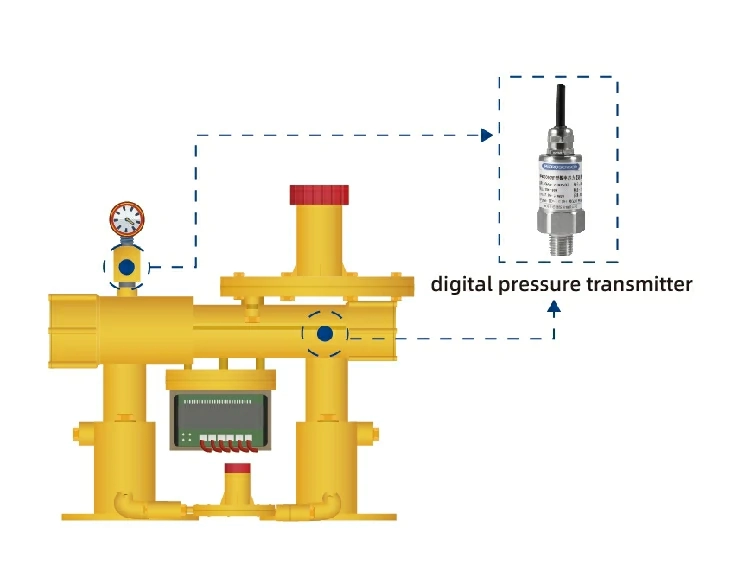

The main function of the gas regulator is to adjust the higher gas inlet pressure to the set lower gas outlet pressure. With a series of changes in gas consumption and inlet pressure, the gas regulator will automatically keep the outlet pressure value within a certain range and play a stabilising role. The pressure transmitter is the core component of the regulator.

more info...

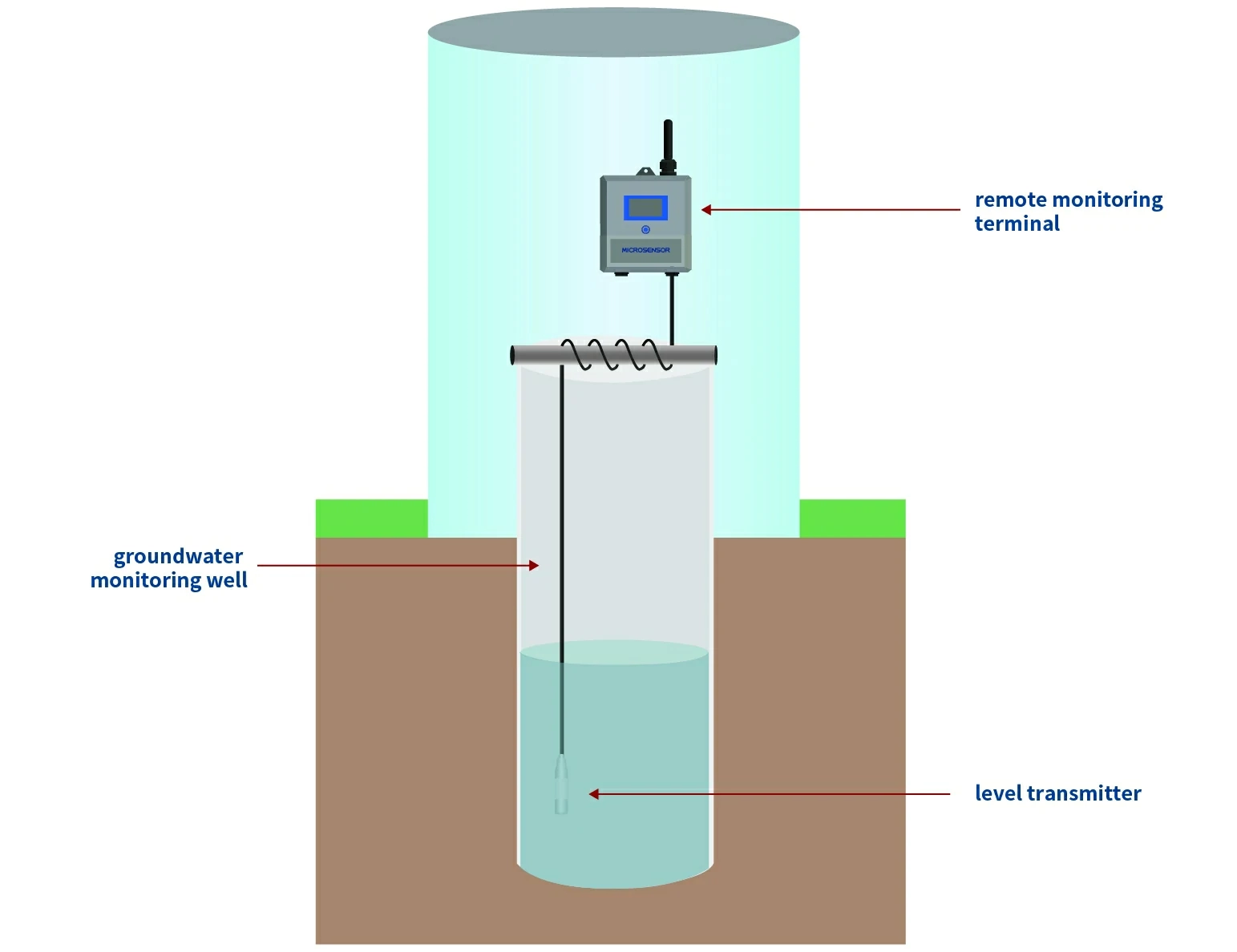

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

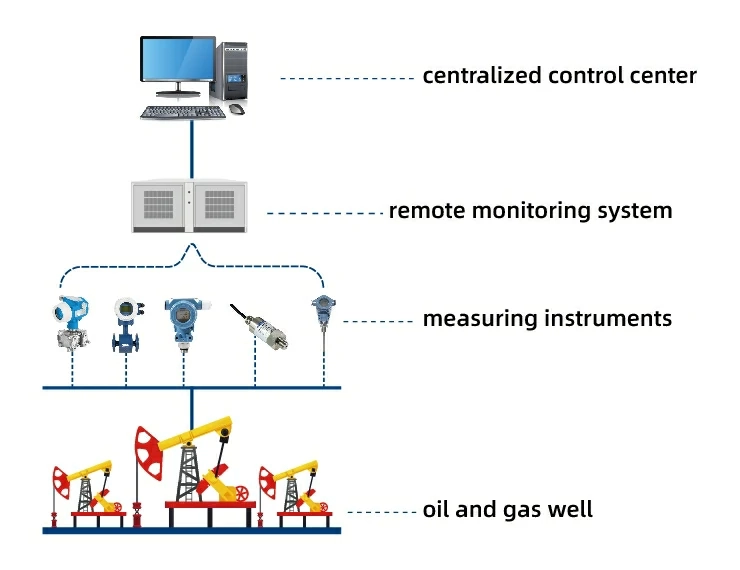

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...

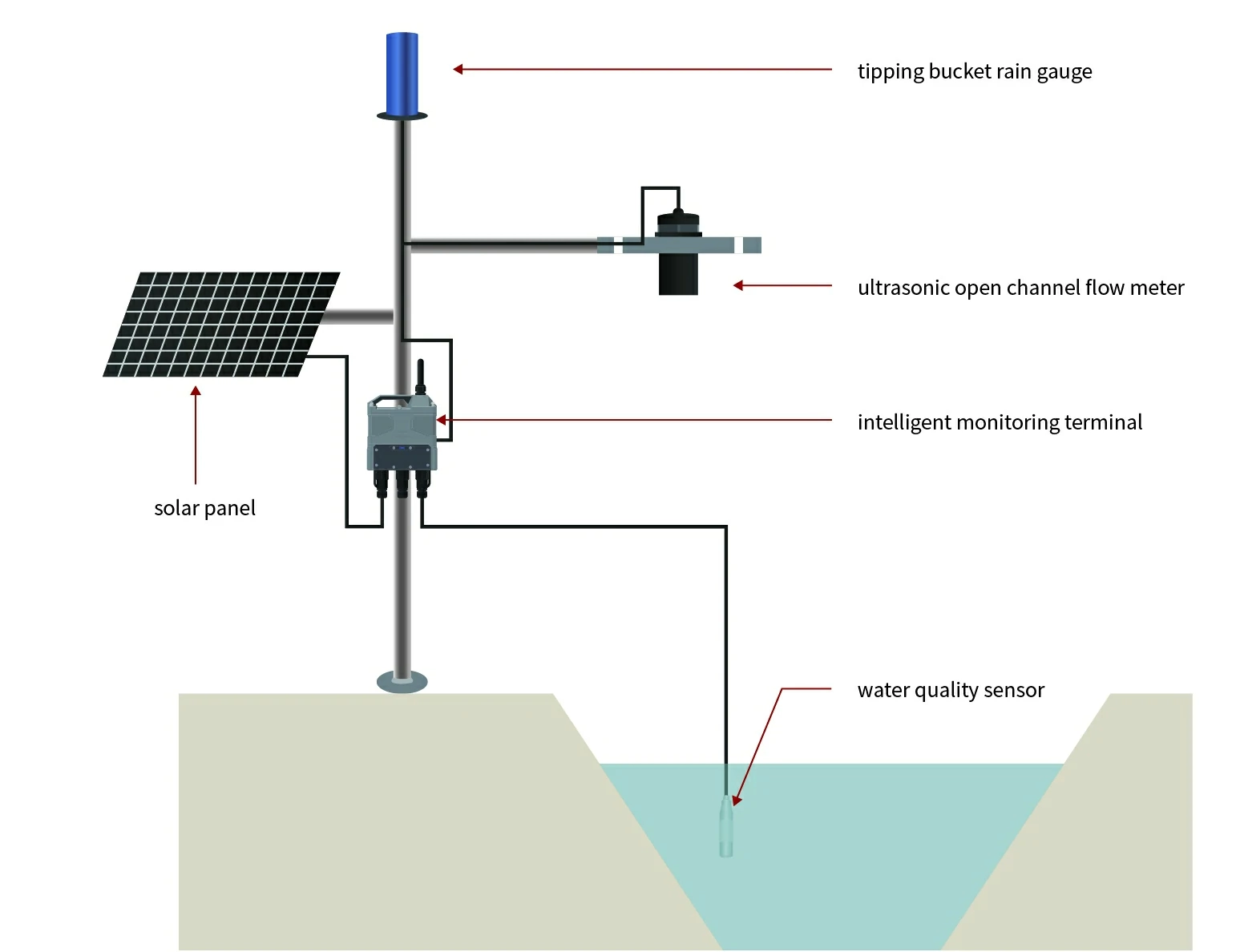

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...