22mm Submersible Level Transmitter

Φ22mm

1m, 2m, 5m, 7mH2O

Accuracy: ±1%FS

MPM489WZ1

Used For

Underground Water, Deep Well, Borehole

Leave a MessageMPM489WZ1 Thin Type Level Transmitter has a smaller diameter than conventional products. Therefore, MPM489WZ1 is more suitable for field application scenarios where space is limited. Inside the outer diameter of 19mm is a stable and reliable piezoresistive pressure sensing element and a dedicated PCB element. The long-term use of the MPM489WZ1 in liquids compatible with the transmitter's material of construction is due to the vented cable attached to the transmitter housing. The standardized signal output dramatically facilitates the operation and automatic control of the work site. Standardized signal output matches low-power operation scenarios to meet the diversity of customer application requirements. This is also very beneficial to the operation and automation control of the work site. MPM489WZ1 Level Transmitter is suitable for liquid level measurement in groundwater, deep well, drilling and other fields.

Features

• Φ19 Dia, compact size

• Cost-effective, long-term stability

• Integrated structure and adjustment-free

• Construction material optional, more compatible

Specification

• Pressure Range: 10m, 20m, 50m, 100m, 200m H2O

• Overpressure: 1.5 times FS

• Accuracy: ±0.5%FS

• Stability error: Range>20mH2O, ±0.2%FS/year; Range≤20mH2O, 20mmH2O

• Temperature error: ±0.02%FS/℃ (Zero) ±0.05%FS/℃ (Span)

• Operation temp.: -10℃ ~70℃

• Storage Temp.: -20℃ ~85℃

• Power Supply: 11V~28V DC

• Output Signal: 4mA~20mA DC (2-wire)

Image:

MPM489WZ1 Thin Type Level Transmitter has a smaller diameter than conventional products. Therefore, MPM489WZ1 is more suitable for field application scenarios where space is limited. Inside the outer diameter of 19mm is a stable and reliable piezoresistive pressure sensing element and a dedicated PCB element. The long-term use of the MPM489WZ1 in liquids compatible with the transmitter's material of construction is due to the vented cable attached to the transmitter housing. The standardized signal output dramatically facilitates the operation and automatic control of the work site. Standardized signal output matches low-power operation scenarios to meet the diversity of customer application requirements. This is also very beneficial to the operation and automation control of the work site. MPM489WZ1 Level Transmitter is suitable for liquid level measurement in groundwater, deep well, drilling and other fields.

Features

• Φ19 Dia, compact size

• Cost-effective, long-term stability

• Integrated structure and adjustment-free

• Construction material optional, more compatible

Specification

• Pressure Range: 10m, 20m, 50m, 100m, 200m H2O

• Overpressure: 1.5 times FS

• Accuracy: ±0.5%FS

• Stability error: Range>20mH2O, ±0.2%FS/year; Range≤20mH2O, 20mmH2O

• Temperature error: ±0.02%FS/℃ (Zero) ±0.05%FS/℃ (Span)

• Operation temp.: -10℃ ~70℃

• Storage Temp.: -20℃ ~85℃

• Power Supply: 11V~28V DC

• Output Signal: 4mA~20mA DC (2-wire)

3.5, 7, 10, 20, 35, 70, 100, 200mH2O

Accuracy: ±0.1%FS (Typ.)

HART Protocol

DNV approved for ship use

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.5%FS

ModBus-RTU Protocol

MDM7000-DGP Accuracy: ±0.075%,±0.1%,±0.2%URL

MDM7000-DAP Accuracy: ±0.1%、±0.2%URL

MDM7000-DGP Range:60mbar ~400bar

MDM7000-DAP Range: 0.4bar~100bar

Long-term stability: ±0.2% SPAN/10 years

Maximum turndown ratio: 100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

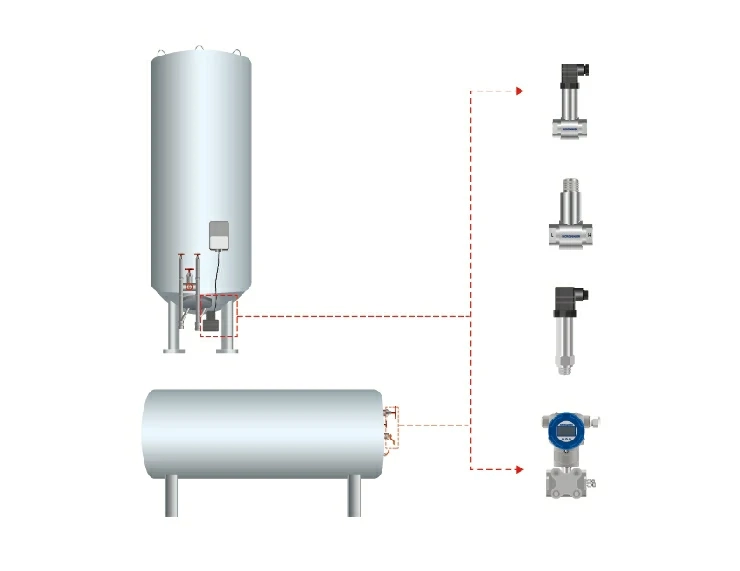

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

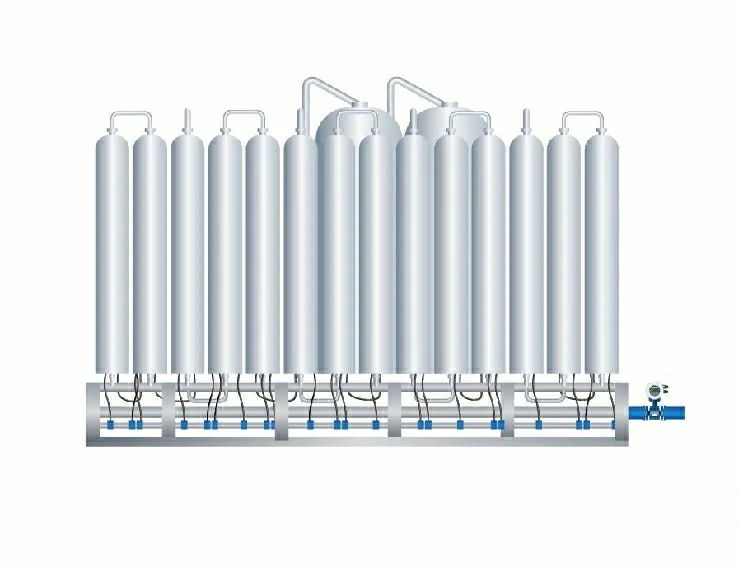

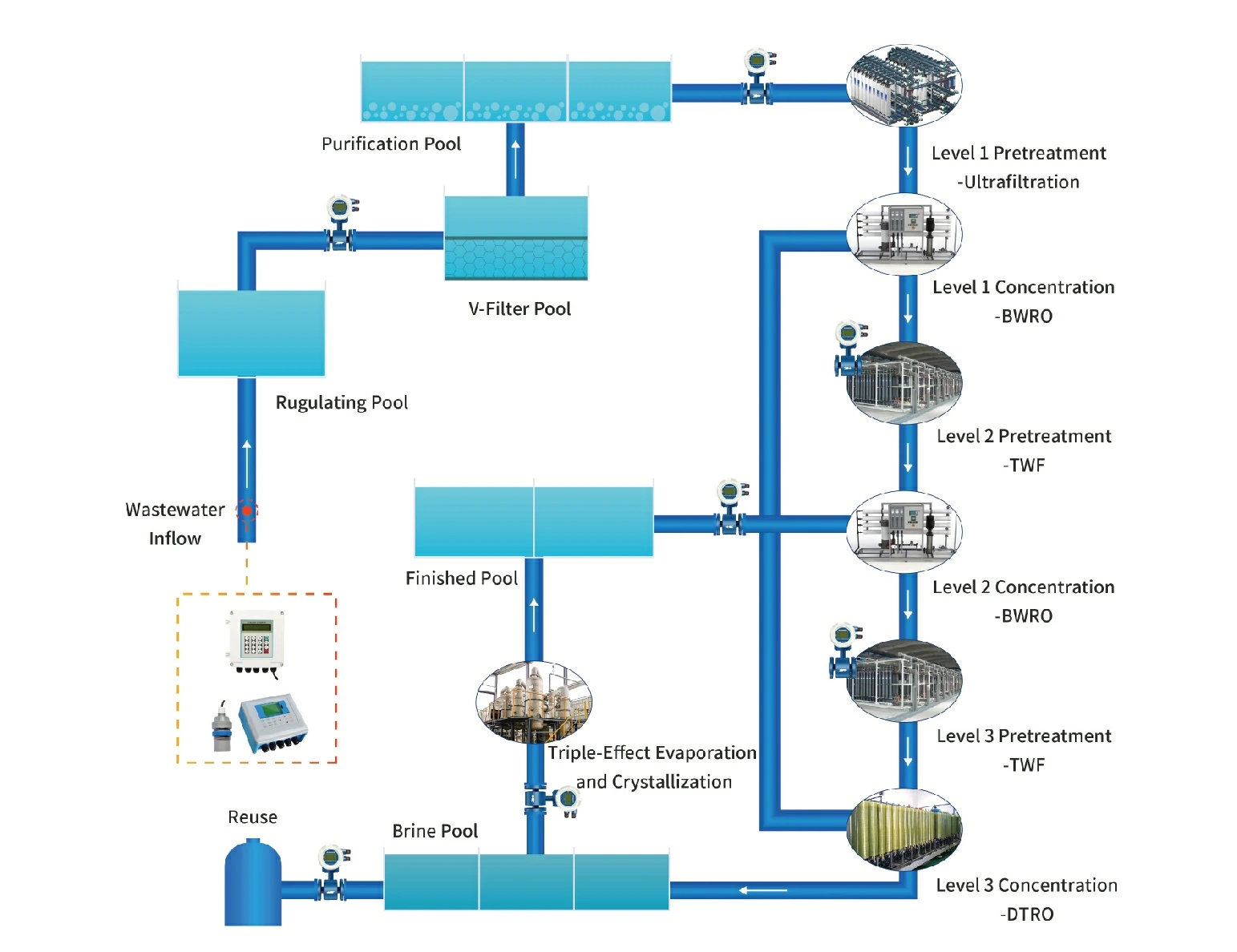

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...

In response to the national sustainable development strategy, enterprises typically install industrial wastewater treatment equipment, such as electromagnetic flowmeters and open channel flowmeters, to monitor and measure wastewater treatment and discharge.

more info...

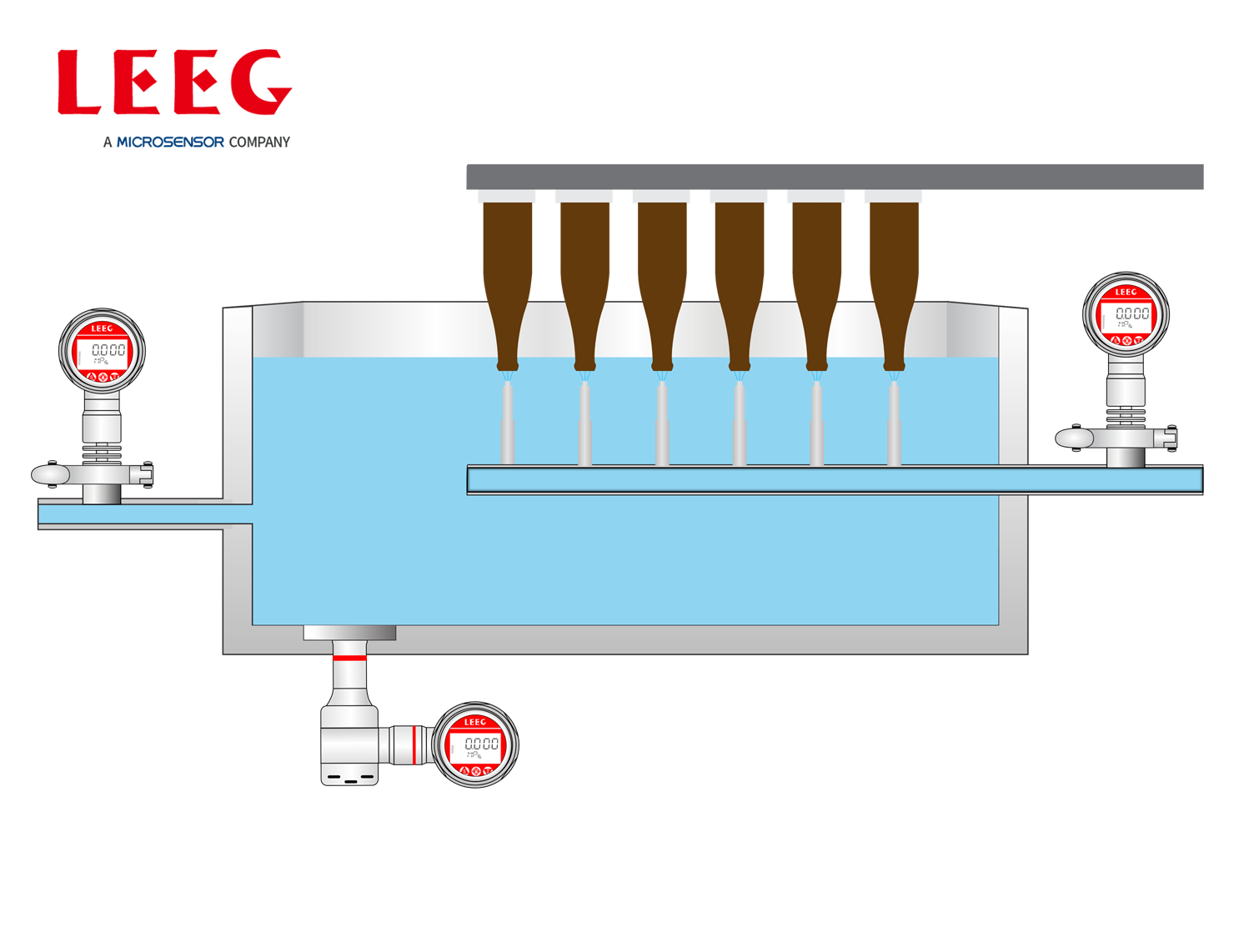

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...